A Large Temperature Difference Freeze-Thaw Circulation System for Improving the Effect of Ground Drilling Gas Drainage

A gas drainage and circulation system technology, applied in earthwork drilling, gas discharge, drilling equipment, etc., can solve the problems of unsatisfactory application effect, limited expansion range of cracks, and difficulty in forming long cracks, so as to increase the number of cracks. effect, improve cracking effect, good cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below.

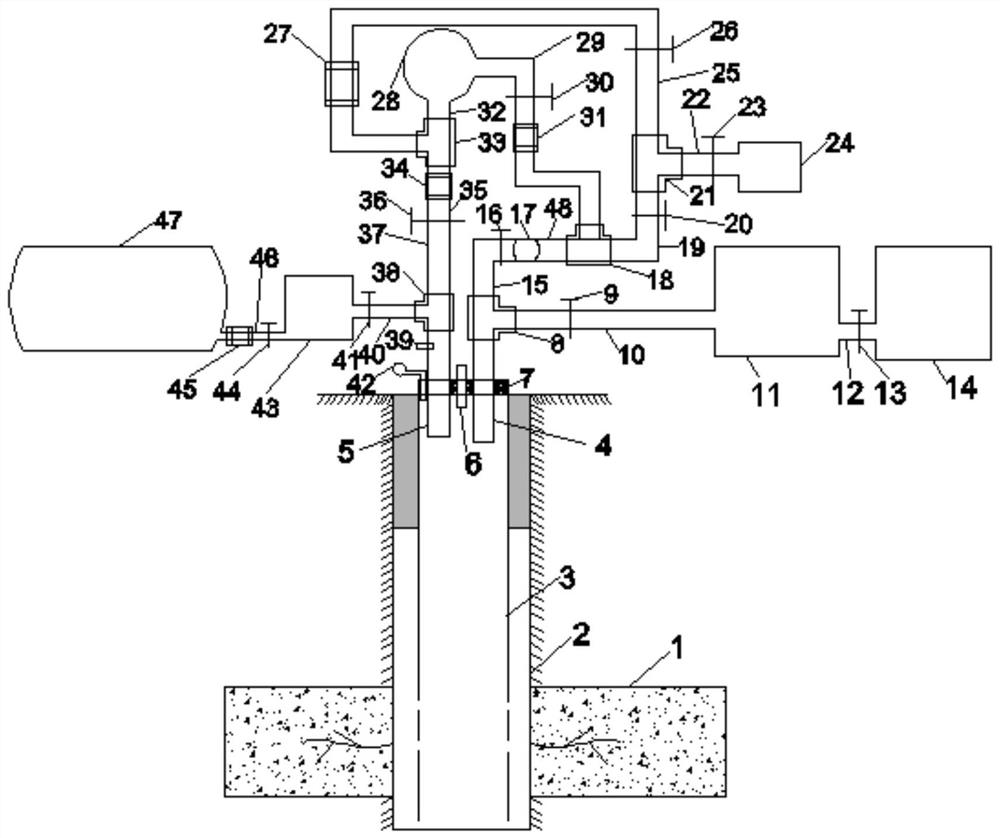

[0012] Such as figure 1 As shown, the present invention includes a first pipeline 4, a first low temperature resistant pipeline 5, a laser rangefinder 6, a drilling sealing cover 7, a first tee joint 8, a second pipeline 10, a pulsation pump 11, a third Pipeline 12, magnetized water generator 14, fourth pipeline 15, nitrogen pressurization device 17, second three-way joint 18, fifth pipeline 19, third three-way joint 21, sixth pipeline 22, nitrogen making Machine 24, seventh pipeline 25, nitrogen heating device 28, eighth pipeline 29, ninth pipeline 32, fourth tee joint 33, tenth pipeline 35, eleventh pipeline 37, liquid nitrogen tee Connector 38, second low temperature resistant pipeline 40, liquid nitrogen pulsating pump 43, third low temperature resistant pipeline 46 and liquid nitrogen tank 47, magnetized water generator 14 is connected with the inlet of pulsating pump 11 through third pipeline 12, pulsating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com