Cross beam formwork support and design and construction method thereof

A well-shaped beam and formwork technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the height difference of the main flute of the bottom formwork of vertical and horizontal well-shaped beams, which cannot meet the requirements of vertical and horizontal well-shaped beams. The requirements for the same height of the bottom formwork, damage to the main flute of the beam bottom formwork, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0168] Such as Figure 1-3 As shown, the well-shaped beam formwork support described in this embodiment includes a beam bottom formwork tray 6, a beam bottom pole 9 and a beam side pole 8, and the beam bottom formwork tray 6 includes two horizontal bars 1 and two vertical poles. Rod 3, a middle rod 5, four four-way 2 and eight extension rods 4, two horizontal bars 1 and two longitudinal bars 3 are welded into a rectangle by four four-way 2, and four four-way 2 outer interfaces are welded The extension rod 4 is welded to the center rod 5 at the midpoint of the length of the two longitudinal rods 3; the extension rod 4 is respectively overlapped with the vertical horizontal rods 14 on both sides of the vertical well-shaped beam 18 and the horizontal well-shaped beam 17, and then the rotating fastener is used 13 is firmly connected, and is firmly connected with the beam side vertical rod 8 of the horizontal well-shaped beam 17 by cross fasteners 7; The top of the pole 9 adopts t...

Embodiment 2

[0170] On the basis of Embodiment 1, this embodiment provides a method for designing and constructing a well-shaped beam formwork support, including the following steps:

[0171] 1. Construction drawing design of the well-shaped beam formwork support:

[0172] 1) On-site collection and confirmation of the material types, specifications and physical and mechanical performance indicators used for the formwork support of the well-shaped beam;

[0173] 2) Grasp the elevation, span, spacing and section size of the well-shaped beam;

[0174] 3) Understand the site foundation type and site drainage conditions;

[0175] 4) According to the above conditions and parameters, carry out the construction drawing design of the well-shaped beam formwork support according to the well-shaped beam formwork support structure;

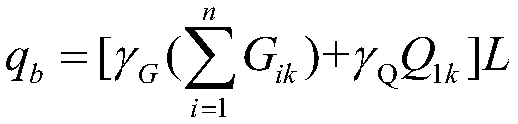

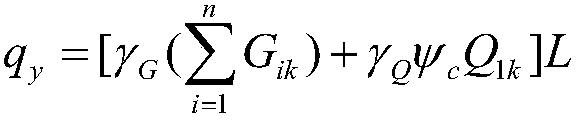

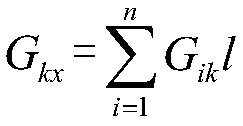

[0176] 2. Calculation of carrying capacity:

[0177] 1) Determine the calculation unit:

[0178] The maximum spacing area between the beam bottom vertical rod 9 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com