Larsen steel sheet pile cofferdam and construction method thereof

A Larsen steel sheet pile and cofferdam technology, which is applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of large water flow shock and fluctuation, reduce the service life of steel sheets, and affect the construction process, so as to ensure pollution, The effect of prolonging the service life and saving the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

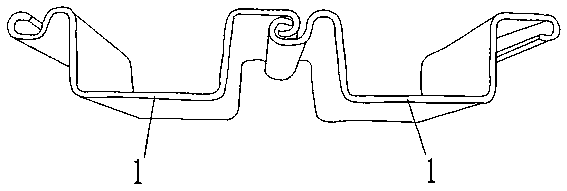

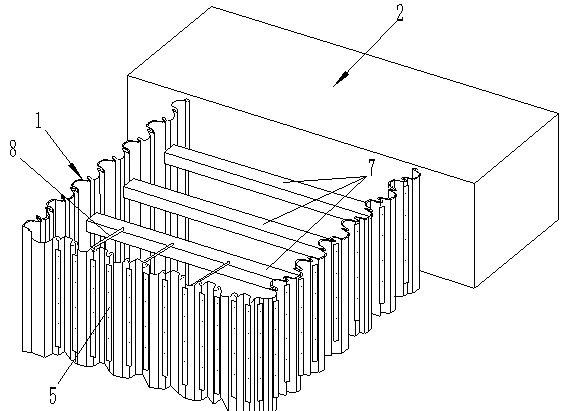

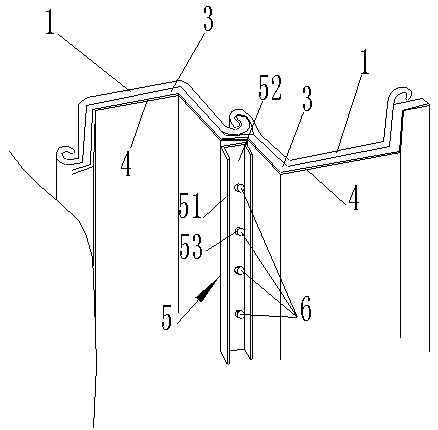

[0041] see Figure 1-6 , a Larsen steel sheet pile cofferdam, including a number of Larsen steel sheet piles 1 that are spliced adjacently, and a number of Larsen steel sheet piles 1 are surrounded by a U-shape, and the open end of the U-shape is against the river bank 2; a number of Larsen steel sheet piles 1 and bank 2 is the backwater side, and the outer side of some Larsen steel sheet piles 1 is the surface water side; some Larsen steel sheet piles 1 and river bank 2 are surrounded by backfill soil, and the top surface of the backfill soil is in contact with the Larsen steel sheet piles. The top surface of the pile 1 is flush, which constitutes the operation platform and the vehicle walking passage; the surface water side of each Larsen steel sheet pile 1 is sequentially fitted with a buffer layer 3 and an anti-corrosion plate 4; The j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com