Road surface joint-cutting machine being convenient to repair blade in road construction

A technology of slitting machine and blade is applied in the field of road slitting machines for highway construction, which can solve the problem of inconvenient maintenance of the blade, save time and effort in the disassembly process, enhance the seismic performance, and reduce the work burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

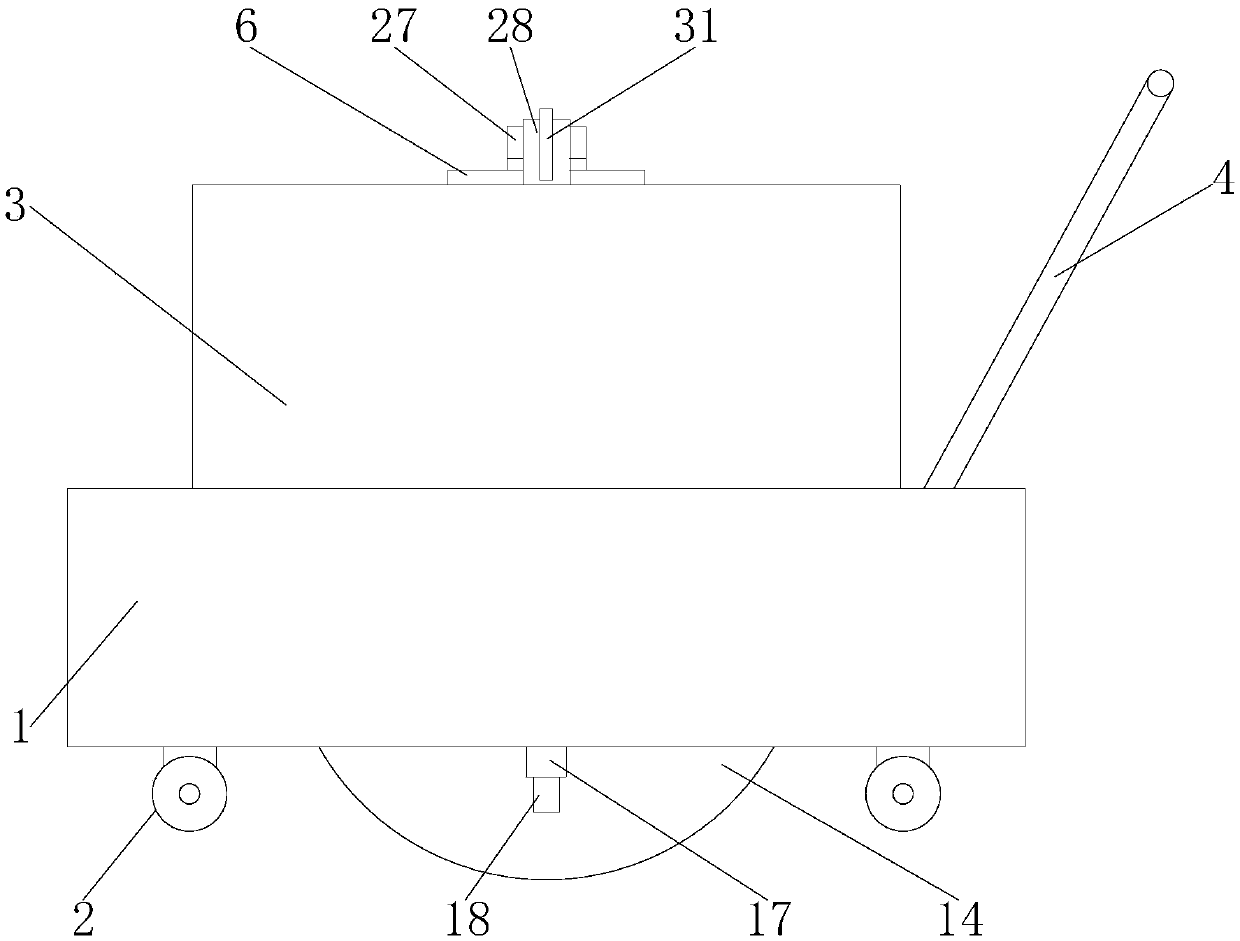

[0017] First implementation: see Figure 1-2 A road surface cutting machine for road construction that is convenient for maintaining blades, comprising a housing 1, moving wheels 2 are arranged at the four corners of the bottom of the housing 1, a water tank 3 is fixedly connected to the midpoint of the top of the housing 1, and the housing 1 The rear side of the top is fixedly connected with a push handle 4, the top of the inner wall of the water tank 3 is provided with a liquid injection port 5, and the position corresponding to the liquid injection port 5 on the top of the water tank 3 is provided with a liquid injection plug 6 used in conjunction with it, and the inner wall of the housing 1 A partition 7 is fixedly connected to the top, and a slitting motor 8 is arranged inside the housing 1 and on the left side of the partition 7. The top and bottom of the slitting motor 8 are fixedly connected with a stabilizing block 9, and the stabilizing block 9 is far away from the sl...

no. 2 approach

[0020] The second embodiment: referring to claim 1, a road surface cutting machine for road construction that is convenient for maintaining blades, including a housing 1, and four corners of the bottom of the housing 1 are provided with movable wheels 2 that can be lifted and lowered. A water tank 3 is fixedly connected to the midpoint of the top of the body 1, and a push handle 4 is fixedly connected to the rear side of the top of the housing 1. The top of the inner wall of the water tank 3 is provided with a liquid injection port 5, and the top of the water tank 3 corresponds to the injection port. The position of the liquid port 5 is provided with a liquid injection plug 6 used in conjunction with it, and a partition 7 is fixedly connected to the inner wall of the housing 1 , and a slit is provided inside the housing 1 and on the left side of the partition 7 Motor 8, the top and the bottom of described slitting motor 8 are all fixedly connected with stabilizing block 9, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com