An all-in-one machine for lifting and feeding precoded paper and printing machine

A pre-coded paper and all-in-one machine technology, which is applied in thin material processing, object separation, transportation and packaging, etc., can solve problems such as difficult consistency control of the adjustment amount on both sides, inability to automatically adjust, inaccurate position, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

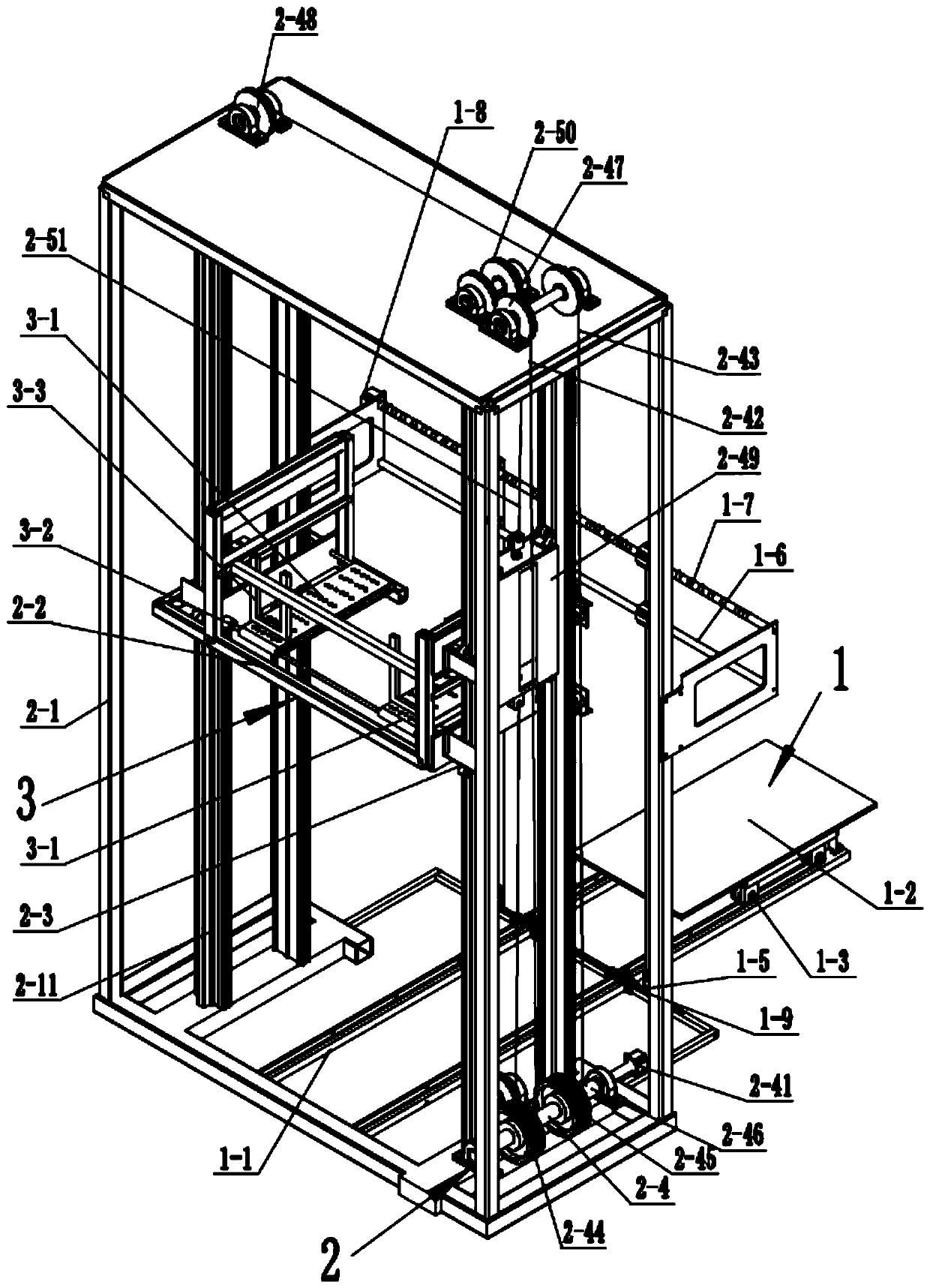

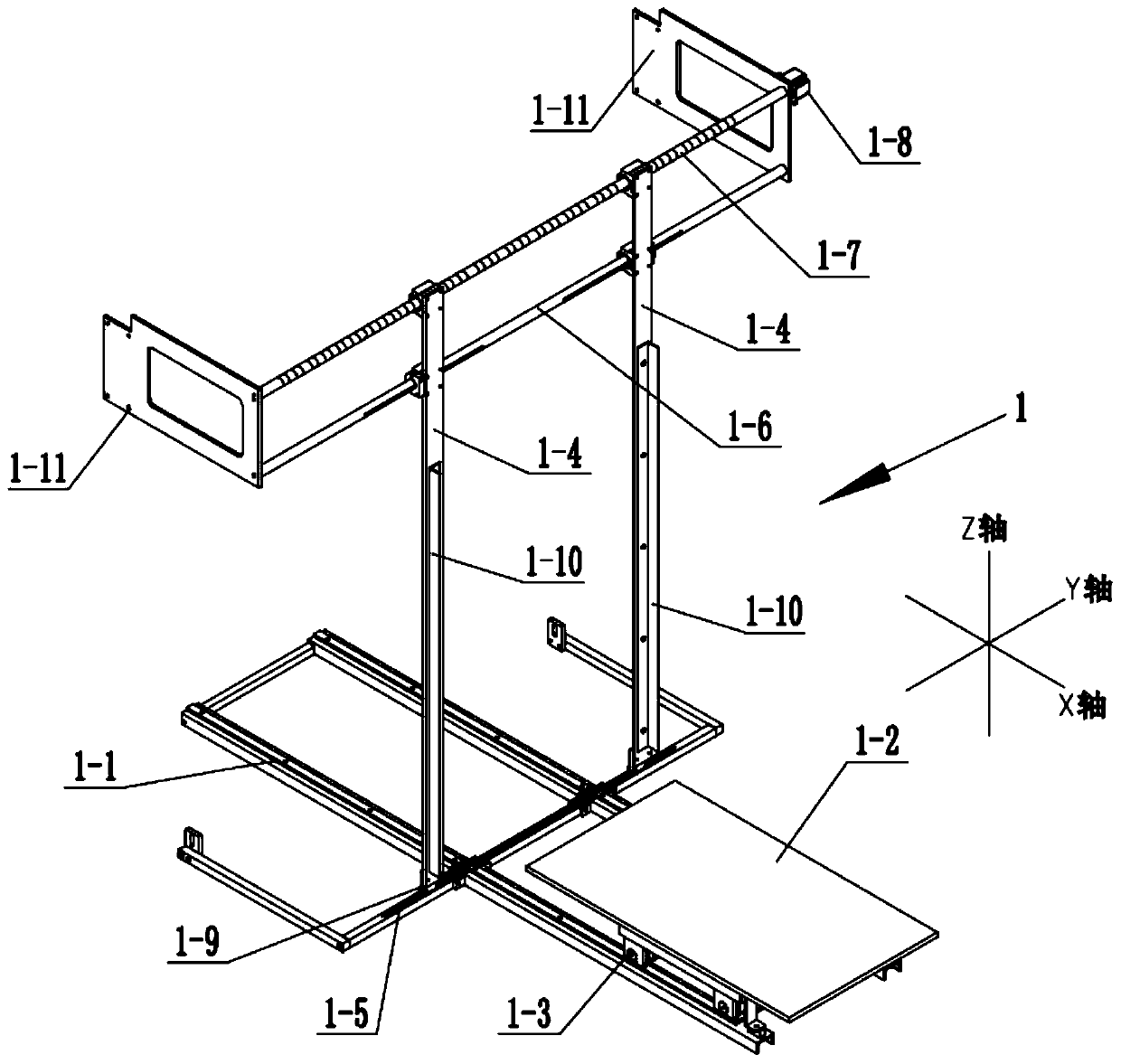

[0065] Embodiment one: see Figure 1-11 , an all-in-one machine for lifting and feeding pre-coded paper, which includes a pre-coded paper device 1 , a paper lifting device 2 and a paper feeding device 3 .

[0066] The pre-packing device 1 includes an X-guiding rail 1-1, a paper support plate 1-2, a wheel 1-3, two Z-directing beams 1-4, a Y-guiding groove 1-5, and a Y-guiding rod 1-6. , Y direction screw mandrel 1-7 and first motor 1-8.

[0067] Preferably, there are two X-guiding rails 1-1.

[0068] A wheel 1-3 is arranged below the paper supporting vehicle plate 1-2, and the wheel 1-3 matches the X-direction rail 1-1.

[0069] Preferably, the X guide rail 1-1 is equipped with a rail car, and the rail car has a paper support plate 1-2 and wheels 1-3.

[0070] Preferably, the railcar is driven automatically.

[0071] The wheel 1-3 is mated with the X-guiding rail 1-1, and the Y-guiding groove 1-5 is vertically crossed with the X-guiding rail 1-1.

[0072] The two Z-directi...

Embodiment 2

[0109] Embodiment 2: A printing machine, which includes the integrated machine for lifting and feeding pre-coded paper described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com