Ship square box segment structure and assembling method thereof

A segmented structure and assembly method technology, which is applied to ship parts, ship construction, transportation and packaging, etc., to achieve the effect of reducing the number of hoisting, reducing manufacturing time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the accompanying drawings.

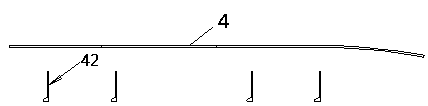

[0035] Refer to attached figure 1 And attached figure 2 , the installation method for conventional square boxes. At present, in the segmental manufacturing of the bottom of the ship, the commonly used manufacturing method is to assemble the parts after assembly. Due to the different hull structures, the plates in some areas can be made into segments, but the plates in some areas cannot be made into segments. At this time, there are fewer parts that can be installed, and not enough segments have been formed, so that the number of hoisting increases during segmental assembly, which affects the segmental manufacturing time.

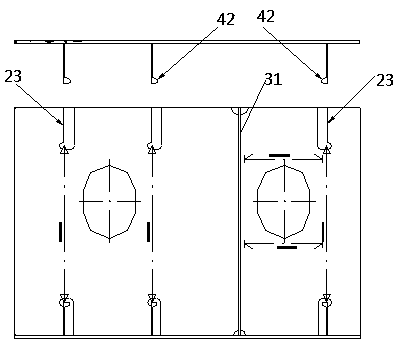

[0036] Refer to attached image 3 - attached Image 6 ,

[0037] A ship square box segmented structure, comprising an inner bottom plate segment 1, a rib plate segment 2, a girder segment 3 and an outer plate segment 4, the inner bottom plate s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com