Rear suspension balance shaft support

A technology of balancing shaft support and rear suspension, applied in the direction of suspension, interconnection system, transportation and packaging, etc., can solve the problems of unreasonable structure, weak bearing capacity, weak torsional moment capacity, etc., and achieve unit mass Small, high strength and rigidity, full-featured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

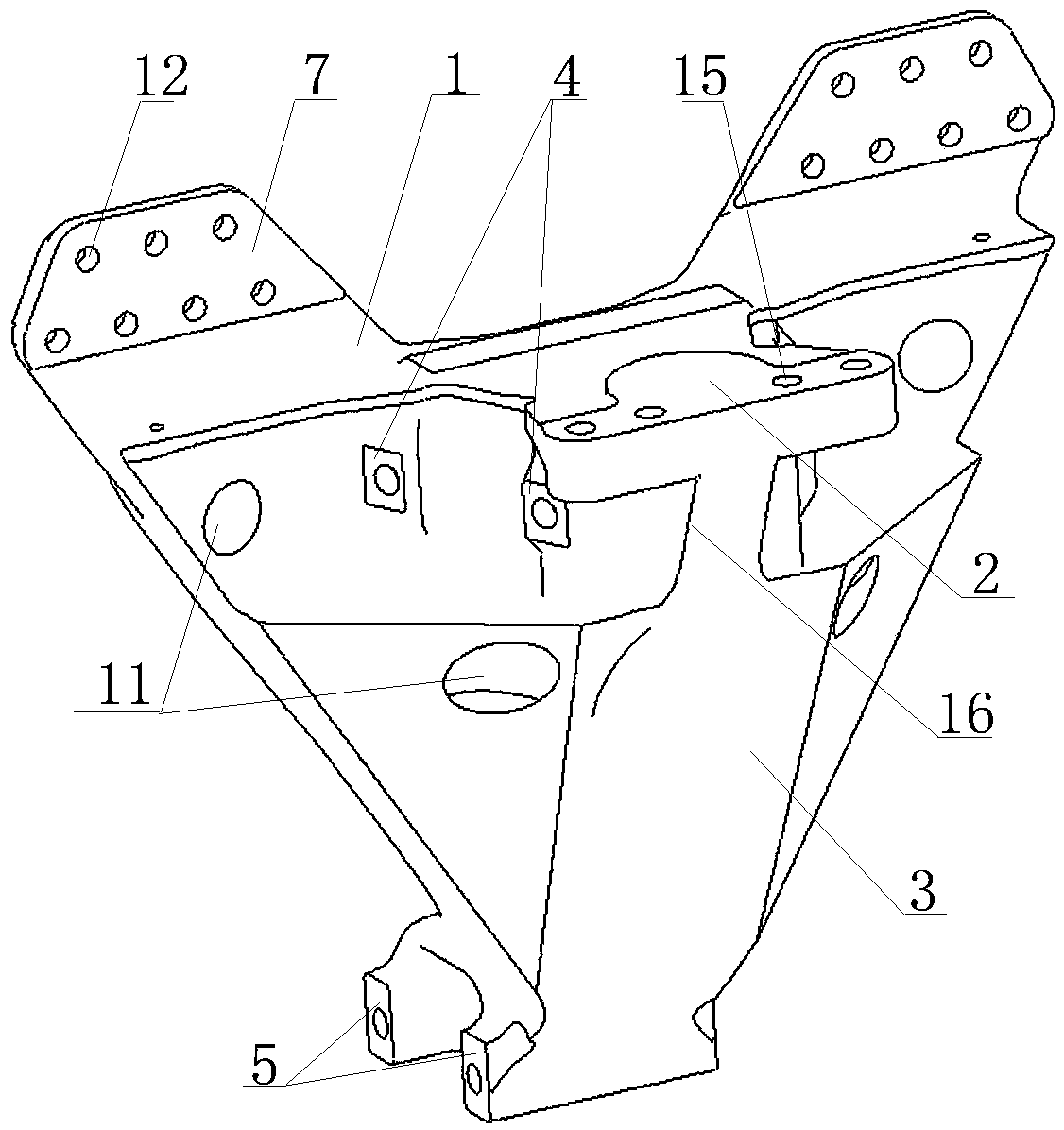

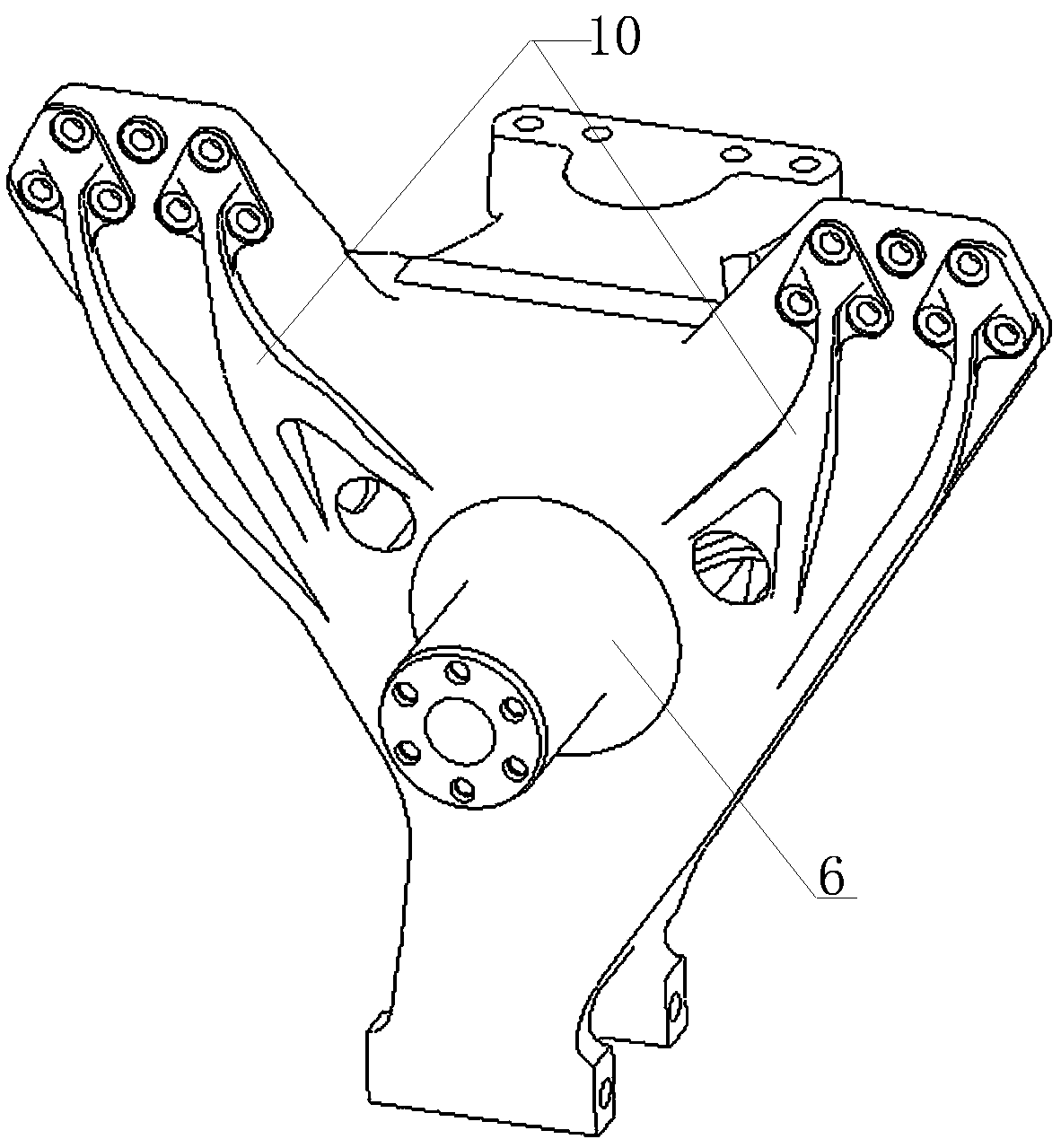

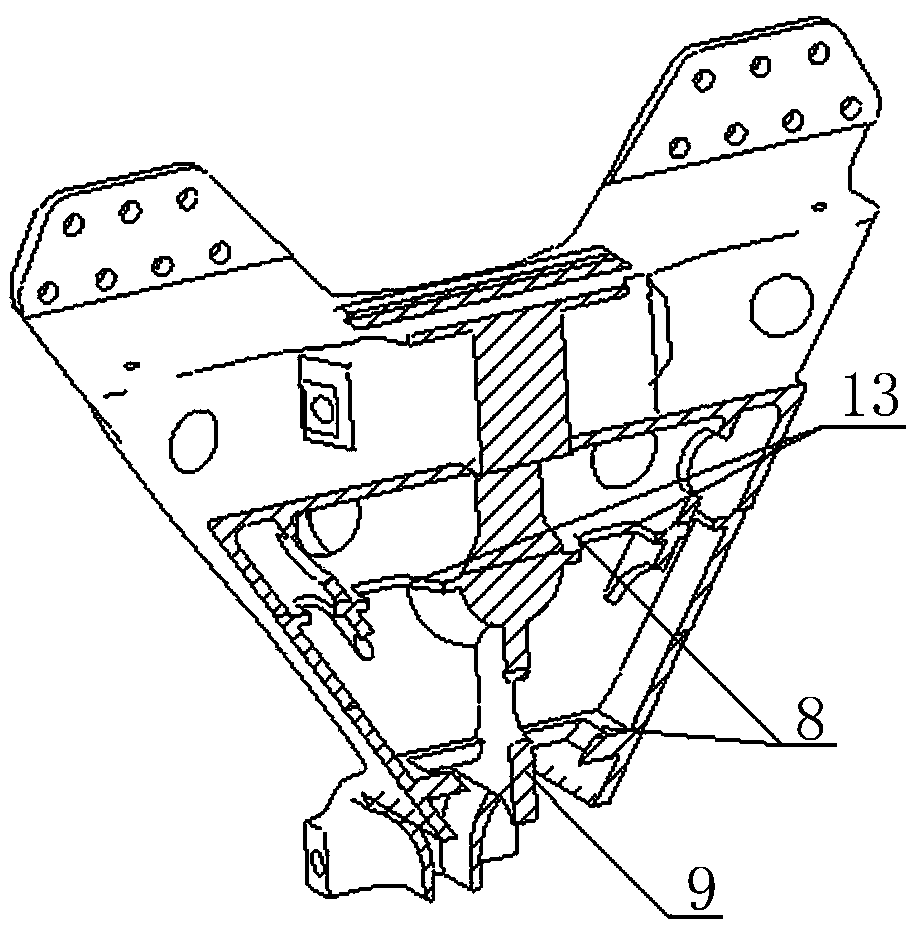

[0025] Attached below Figure 1-5 Specific embodiments illustrate the present invention in further detail.

[0026] Such as Figure 1-5 The rear suspension balance shaft support shown mainly includes a plane base plate 1 distributed vertically in a flat plate structure, a beam mounting plate 2 perpendicular to the upper front side of the plane base plate 1, and a cavity forming a closed cavity structure with the plane base plate 1 body body 3.

[0027] Two support ears 7 are symmetrically connected to the left and right sides of the upper part of the plane base plate 1, and each support ear 7 is provided with a total of seven vehicle frame longitudinal beam mounting holes 12 distributed three times up and down four. 7 are provided with support ear reinforcing ribs 10, and the two support ears 7 are fixedly connected to the vehicle frame longitudinal beam by bolts.

[0028] The crossbeam mounting plate 2 is provided with a frame crossbeam mounting hole 15 for installation an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com