Mechanism for quickly retracting and downwardly moving die

A mold mechanism and fast technology, applied in the direction of presses, manufacturing tools, etc., can solve the problem that the main structure of the mold and the auxiliary mechanism cannot be driven synchronously, and achieve the effect of ensuring full utilization and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

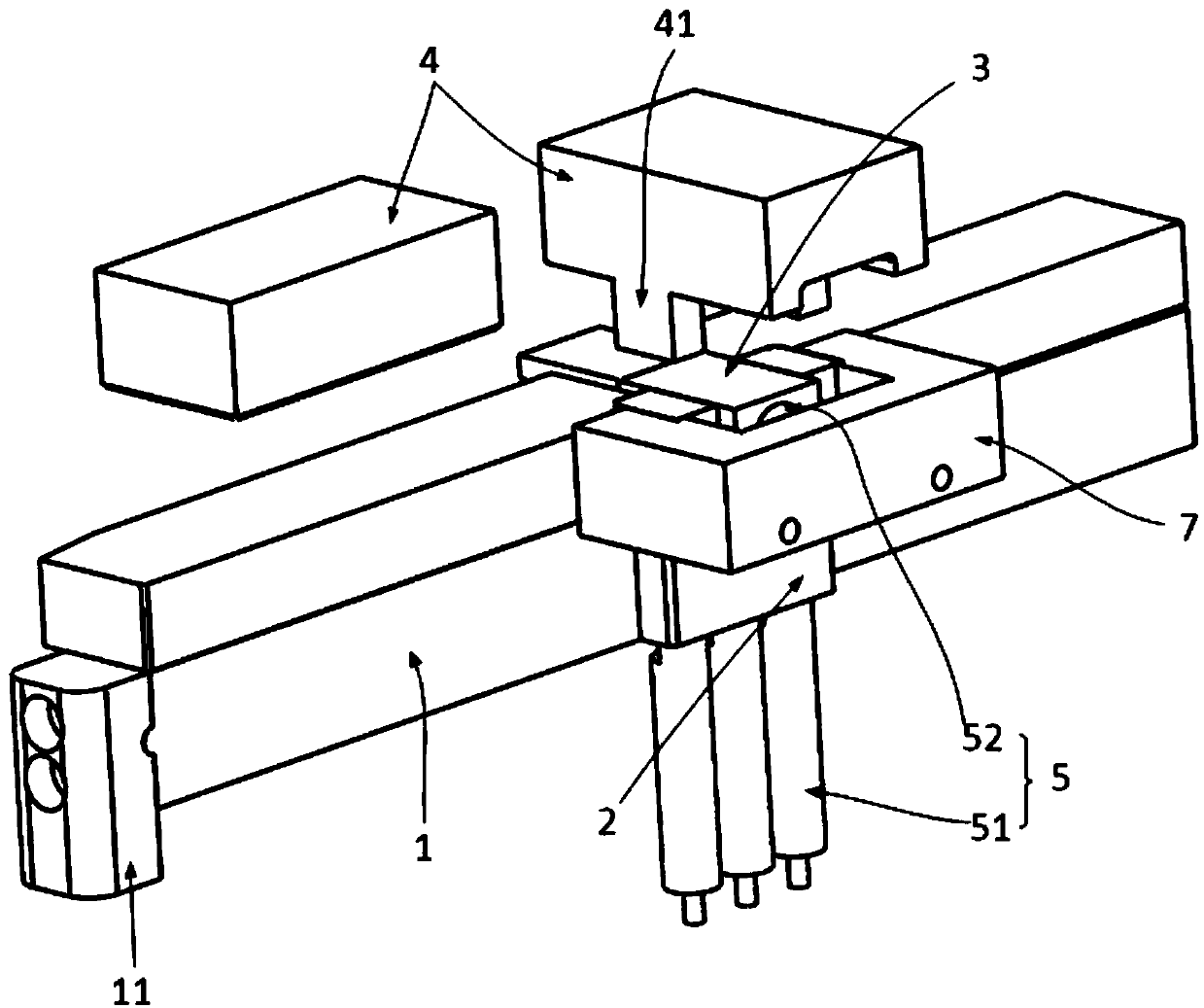

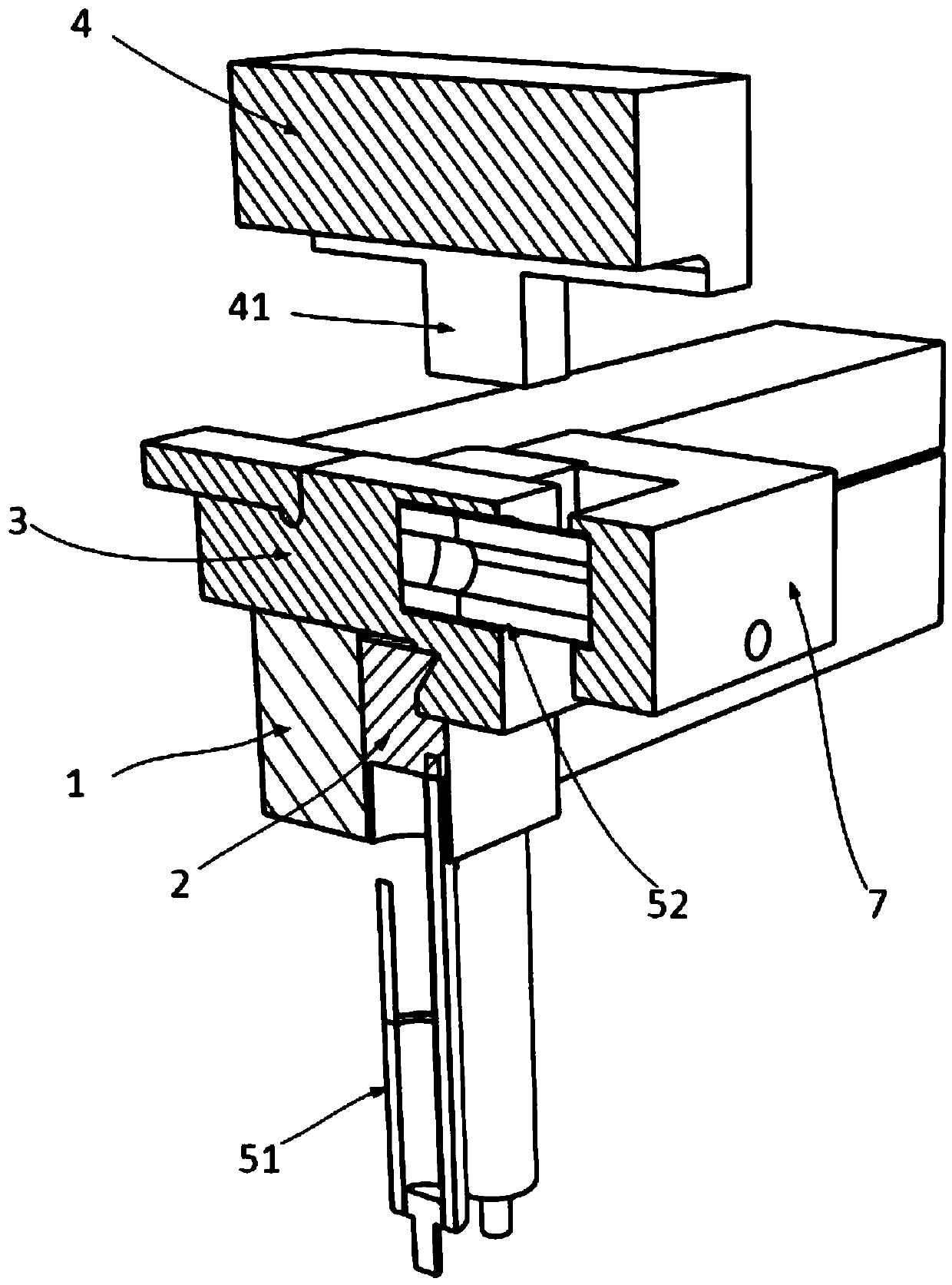

[0032] This embodiment provides a quick return and move down mold mechanism, such as Figure 1-2 shown, including:

[0033] Lifting main body 1;

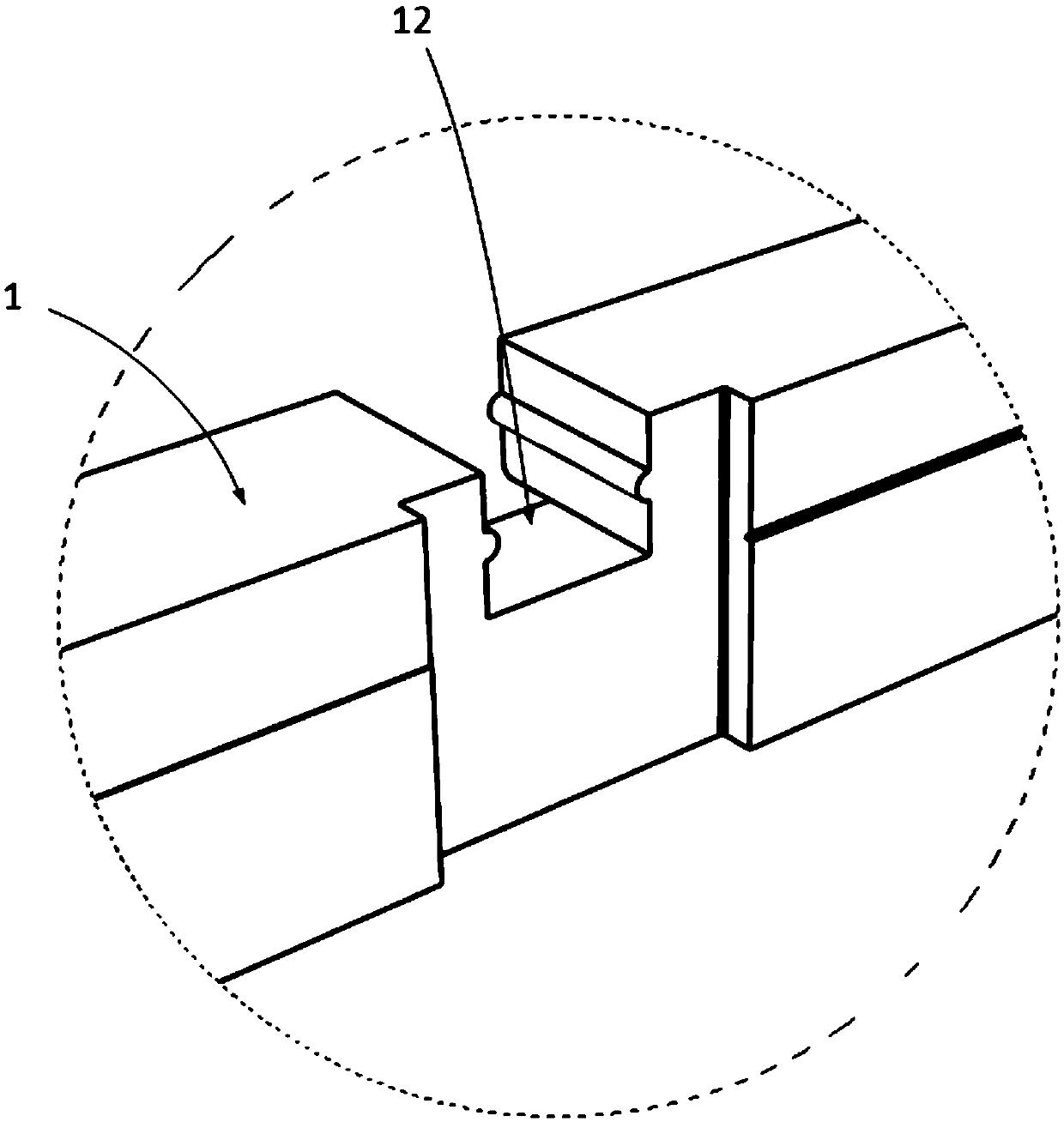

[0034] The push block 2 is installed on the side of the lifting body 1, and the side wall of the push block 2 is formed with a groove 22;

[0035] The mounting block 7 is arranged on one side of the lifting body 1, fixed on the external frame, and formed with a chute for the sliding of the pushing block 2;

[0036] The retracting component 3 is capable of reciprocating sliding, and the retracting component 3 has a bump 33;

[0037] The driving part 4 is located directly above the lifting body 1, and is provided with a claw 41 aligned with the pushing block 2, which can move up and down;

[0038] The reset mechanism 5 is connected with the pushing block 2 and the retracting part 3, and can reset the displaced pushing block 2 and the retracting part 3;

[0039] A groove wall of the groove 22 forms a first slope 221 , a side surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com