Processing method of summer-autumn tea

A processing method and tea technology, applied in the field of summer and autumn tea processing, can solve the problems of waste of fresh tea leaves, low enthusiasm of tea farmers, etc., and achieve the effects of improving utilization rate, increasing sales price and added value, and saving energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

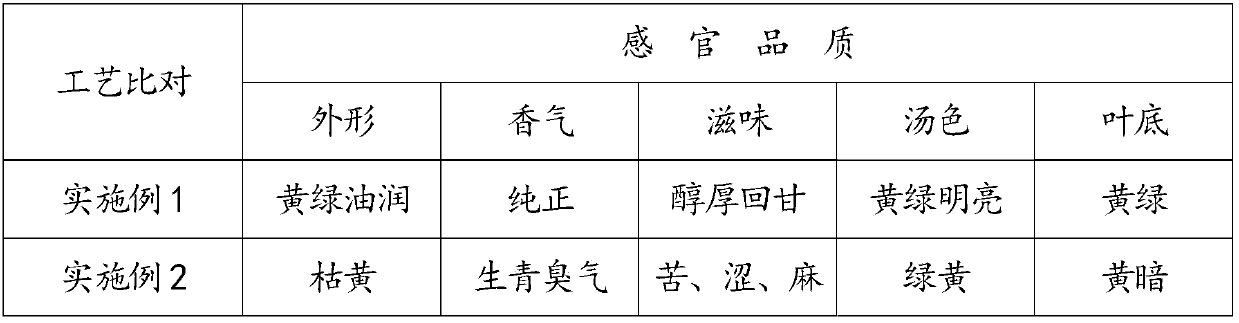

Embodiment 1

[0023] Embodiment 1: (specific embodiment)

[0024] A kind of processing method of summer and autumn tea, it comprises the following steps:

[0025] (1) Raw materials

[0026] The "one bud, two and three leaves" fresh tea picked on sunny days in summer and autumn has a water content of 75%.

[0027] (2) Raw material handling

[0028] The fresh tea leaves after plucking are only spread to cool (reducing the leaf temperature to room temperature) without spreading (spreading to dry and wither), and the moisture content is 75%.

[0029] (3) Finished

[0030] Model: Adopt 80 type drum continuous greening machine.

[0031] The temperature of the drum wall of the greening machine is 200 ° C ~ 280 ° C, the temperature of the front section (280 ° C), the middle section (250 ° C) and the rear section (200 ° C), gradually decreases with the completion of the greening process; the time is 180s ~ 210s. Finishing degree: the water content of the finished leaves is reduced to below 35%;...

Embodiment 2

[0038] Embodiment 2: (comparative example)

[0039] A kind of processing method of summer and autumn tea, it comprises the following steps:

[0040] (1) Raw materials

[0041] The "one bud, two and three leaves" fresh tea picked on sunny days in summer and autumn has a water content of 75%.

[0042] (2) Raw material handling

[0043] The picked fresh tea leaves are spread indoors with a thickness of 2.5cm to 5cm, a drying time of 12 hours, and a water content of 60%.

[0044] (3) Finished

[0045] Model: Adopt 80 type drum continuous greening machine.

[0046] The finishing temperature is 230°C-280°C, and the time is 90s-120s. Finishing degree: the water content of the finished leaves is reduced to below 50%, and the finished leaves are cooled to room temperature after they are out of the pot.

[0047] (4) kneading

[0048] Method: Twice kneading method.

[0049] Kneading machine: use 65-type kneading machine. The green leaves are quickly kneaded by the kneading machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com