Self-adjusting composite radiator

A radiator and self-adjusting technology, which is applied in the combined arrangement of machine/engine and power plant cooling, engine cooling, etc., can solve the problems of large radiator installation space and low heat dissipation efficiency, and achieve saving layout space and reducing Weight, the effect of optimizing the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

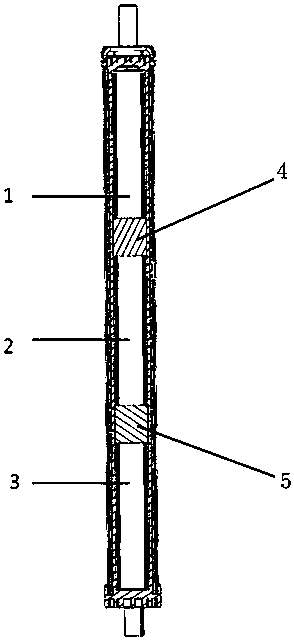

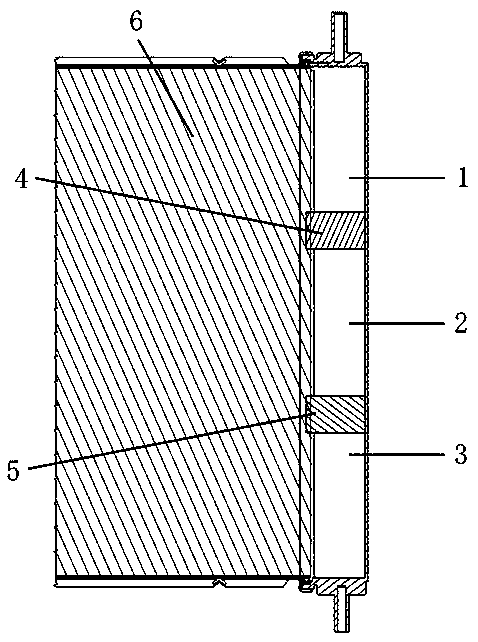

[0018] Please see attached figure 1 and attached figure 2 , a self-regulating composite radiator, comprising a first radiator water chamber 1, a second radiator water chamber 2, a third radiator water chamber 3, a radiator water chamber upper partition 4 and a radiator water chamber lower partition 5. The radiator water chamber upper partition 4 is set between the first radiator water chamber 1 and the second radiator water chamber 2, and the radiator water chamber lower partition 5 is arranged between the second radiator water chamber 2 and the third radiator water chamber. Between the radiator water chambers 3; the upper partition 4 of the radiator water chamber and the lower partition 5 of the radiator water chamber are externally connected with a temperature control device, and the temperature control device controls the opening of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com