Three-sided punched C-shaped steel channel provided with six reinforcing ribs

A technology of reinforcing ribs and C-shaped steel, applied in the direction of load-bearing elongated structural components, structural elements, building components, etc., can solve the problems of unreasonable structural design, affecting the strength of steel grooves, poor section performance, etc., to achieve self-weight The effect of light weight, material saving and excellent cross-sectional performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Now the present invention is further described in conjunction with description of drawings and embodiments:

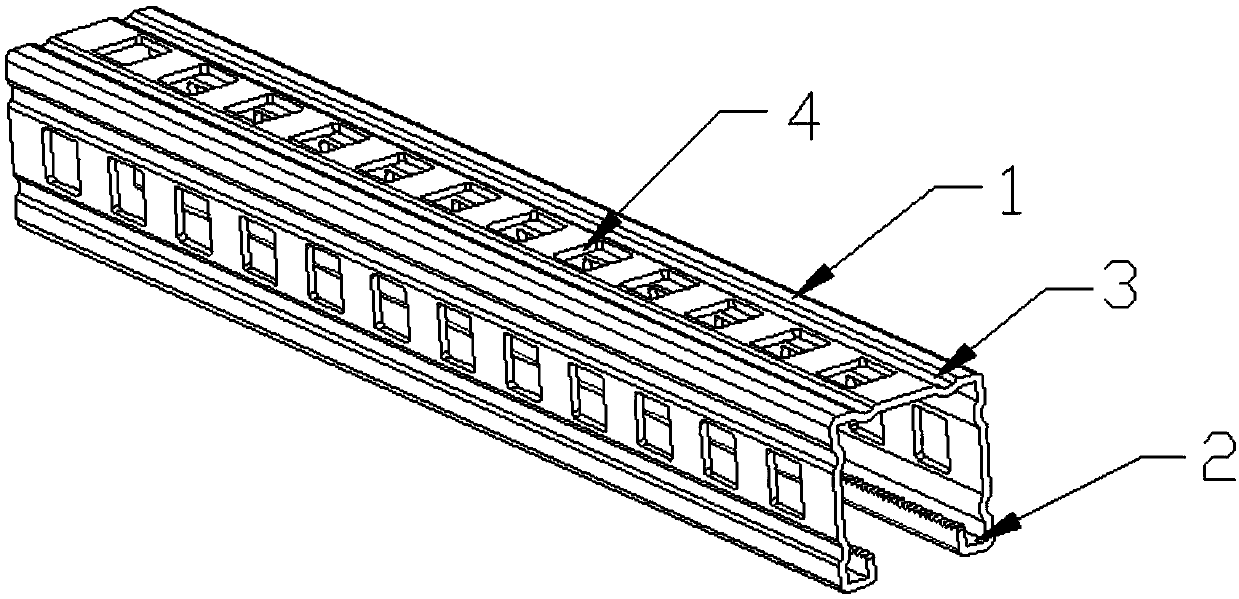

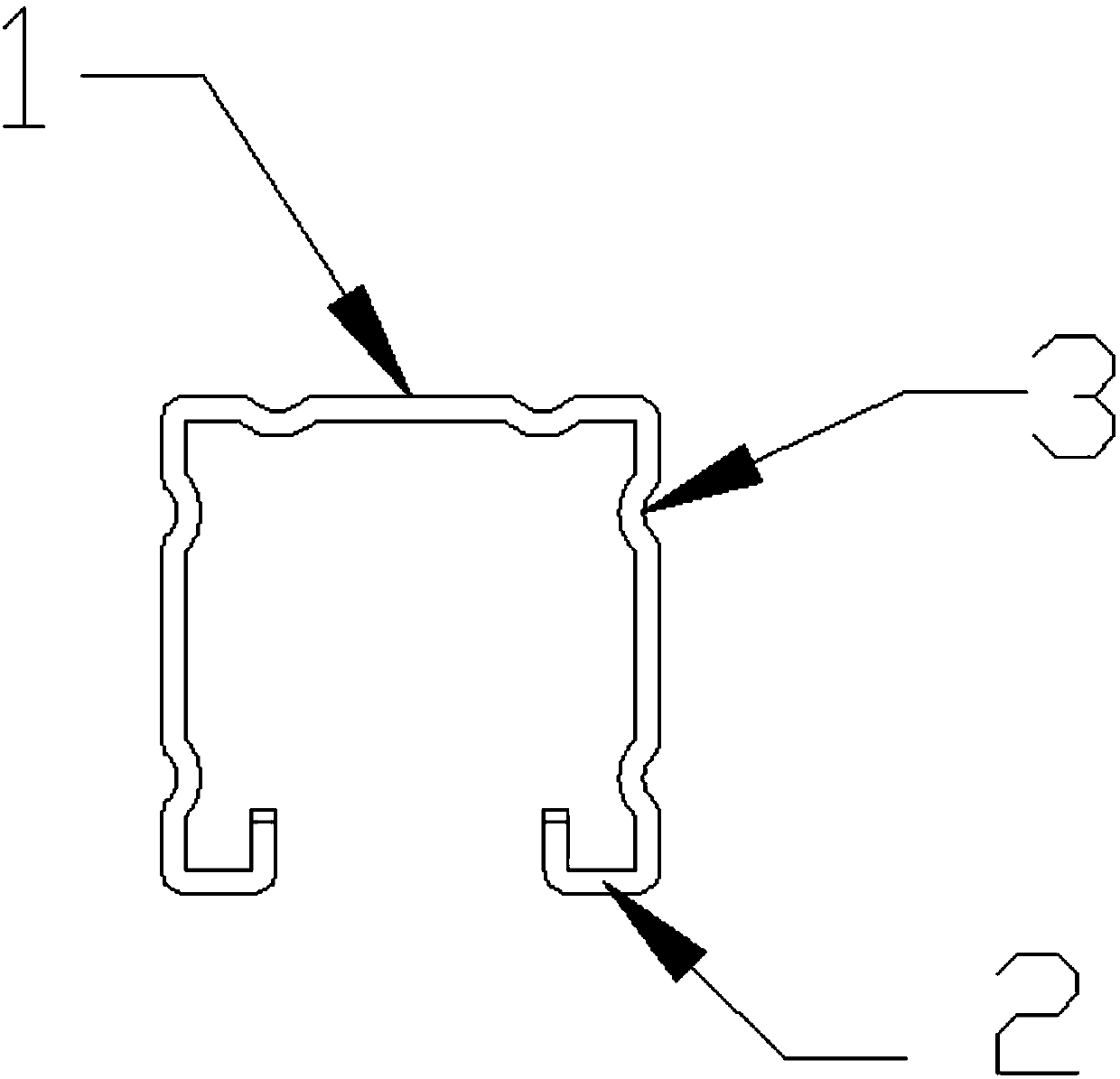

[0022] refer to figure 1 with figure 2 , a three-side perforated C-shaped steel channel with six reinforcing ribs, wherein: the cross-sectional shape of the channel steel 1 is a "C"-shaped structure, and the two side edges of the channel steel continue to bend inwards to form two The second "乚" type structure 2 has a sawtooth structure at the end of the side. The channel steel is provided with three surfaces, and each surface is provided with two parallel reinforcing ribs 3, and the two reinforcing ribs 3 are provided with a There are several through holes 4 .

[0023] refer to Figure 3-6 , a three-sided perforated C-shaped steel channel with six reinforcing ribs, also includes the following production steps:

[0024] The steel plate is conveyed and fed, and the steel plate is sent into the punching and shearing equipment, and the positioning and limit cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com