Wearproof cutting device for liquid crystal glass plate processing

A technology for cutting devices and glass plates, which is applied in the direction of glass cutting devices, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of unfavorable plate processing, plate wear, and inflexible device structure design, and achieve good safety protection effect and location Adjust the smooth effect

Inactive Publication Date: 2019-04-09

深圳市新世纪拓佳光电技术有限公司

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] A cutting device disclosed in the Chinese invention patent application publication specification CN 105946125 A, although a cutting device has a wide range of applications and the setting of the scale can make the movement accurate and meet the cutting requirements, but when processing liquid crystal glass plates, Since different plates have different shapes and structures, the cutting device needs to be more flexible, and the structural design of the general device body is often not flexible enough, so that there are many disadvantages in the processing of the plate, and because the plate is relatively fragile, the general device body There is no protective structure, which will cause the plate to be subject to different degrees of wear during processing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

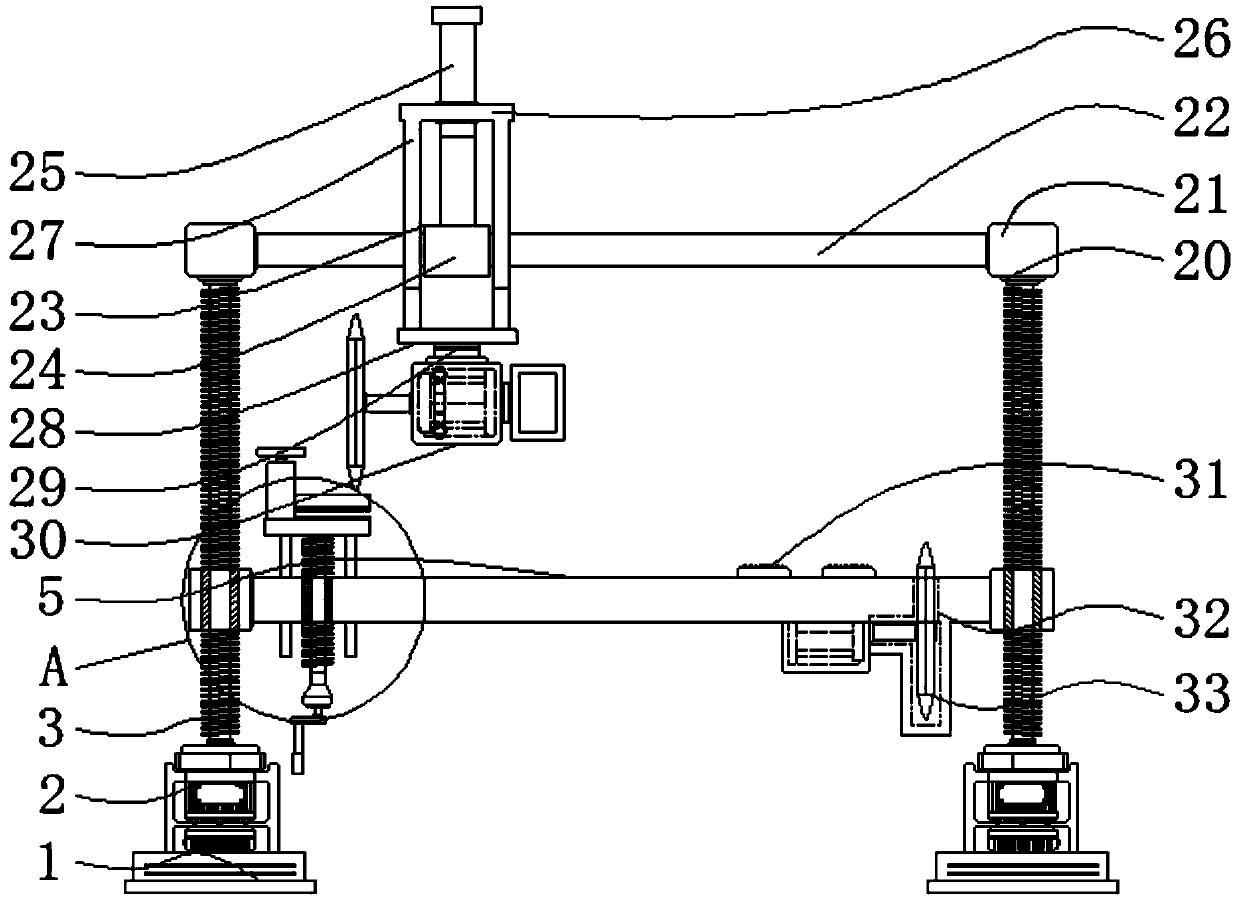

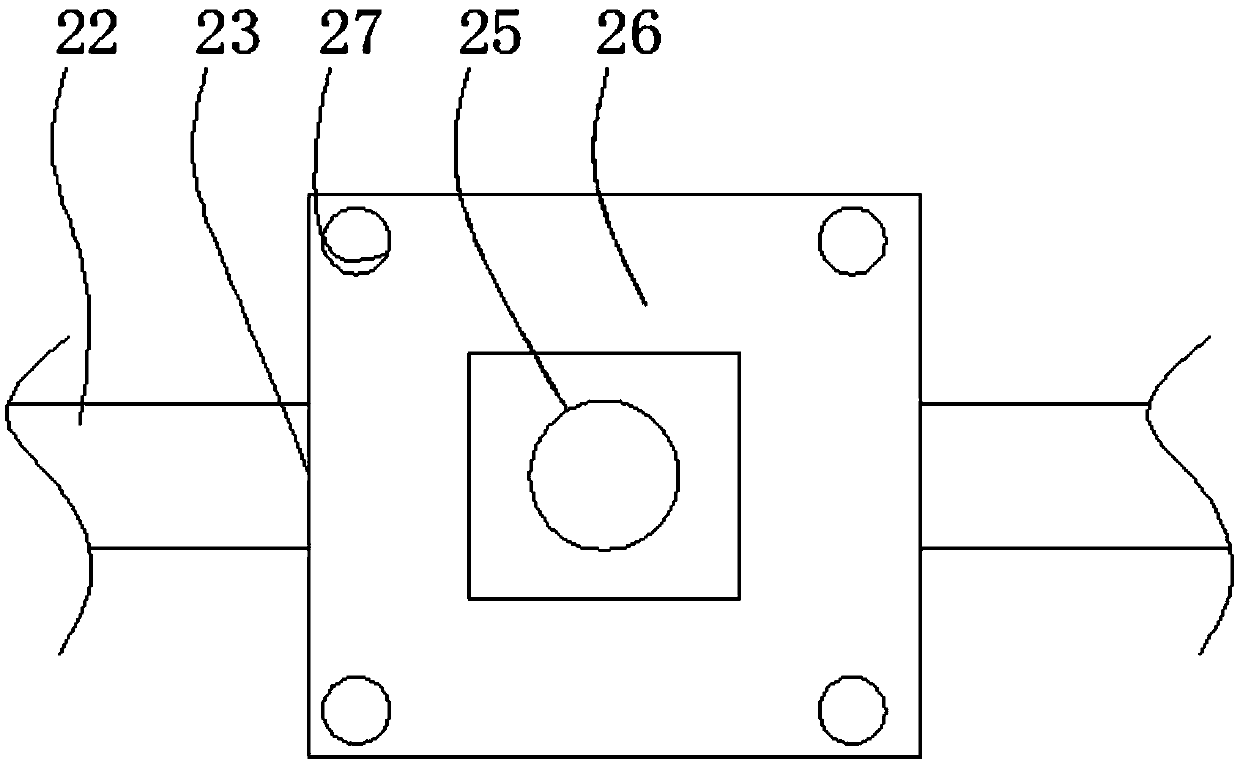

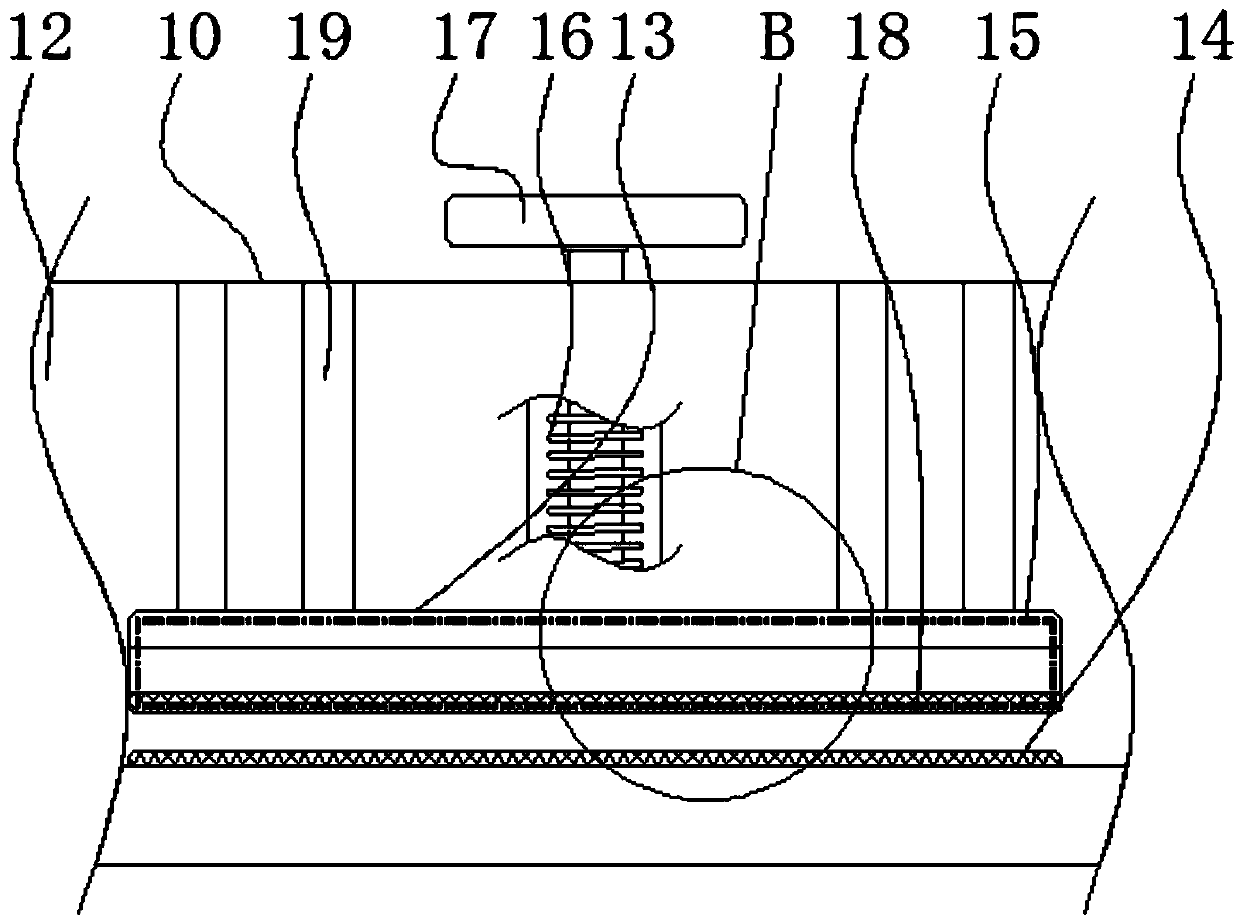

The invention relates to a wearproof cutting device for liquid crystal glass plate processing. The wearproof cutting device comprises a footstand and a locating and cutting device; the upper end of the footstand is provided with a servo motor, and the upper end of the servo motor is connected with a driving lead screw; the outer side of the middle of the driving lead screw is connected with a driving and positioning seat, and the outer wall of the driving and positioning seat is connected with a central connecting plate; a regulating screw is penetrated and connected to the inside of the leftend of the central connecting plate, and the bottom end of the regulating screw is fixedly provided with a crank; the top end of the regulating screw is connected with a connecting bearing, and the left and right ends of the regulating screw are provided with limiting rods; and a snap device is fixedly arranged above the limiting rods. The wearproof cutting device has the beneficial effects that the wearproof cutting device for liquid crystal glass plate processing is provided with side connecting columns and a bottom snap plate, and a top snap plate can drive the bottom snap plate to slide and regulate when sliding and regulating due to the arrangement of the four side connecting columns, and furthermore, it is convenient to stably regulate and use the movable cutting device by virtue ofa horizontal connecting beam.

Description

technical field [0001] The invention relates to the technical field of cutting devices, in particular to an anti-wear cutting device for liquid crystal glass plate processing tools. Background technique [0002] Cutting is a physical action. Cutting in a narrow sense refers to cutting objects (such as food, wood and other objects with low hardness) with sharp tools such as knives; cutting in a broad sense refers to using tools, such as machine tools, flames, etc. to make objects When the glass plate is broken down, the cutting device is often used to perform the plastic operation when the glass plate is processed. [0003] A cutting device disclosed in the Chinese invention patent application publication specification CN 105946125 A, although a cutting device has a wide range of applications and the setting of the scale can make the movement accurate and meet the cutting requirements, but when processing liquid crystal glass plates, Since different plates have different sh...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03B33/023

CPCC03B33/023

Inventor 张坤杨广丰

Owner 深圳市新世纪拓佳光电技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com