Sealant material verification method suitable for airworthiness certification

A sealant, design verification technology, applied in special data processing applications, instruments, aircraft parts, etc., to achieve the effect of improving efficiency, improving reliability, and shortening the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

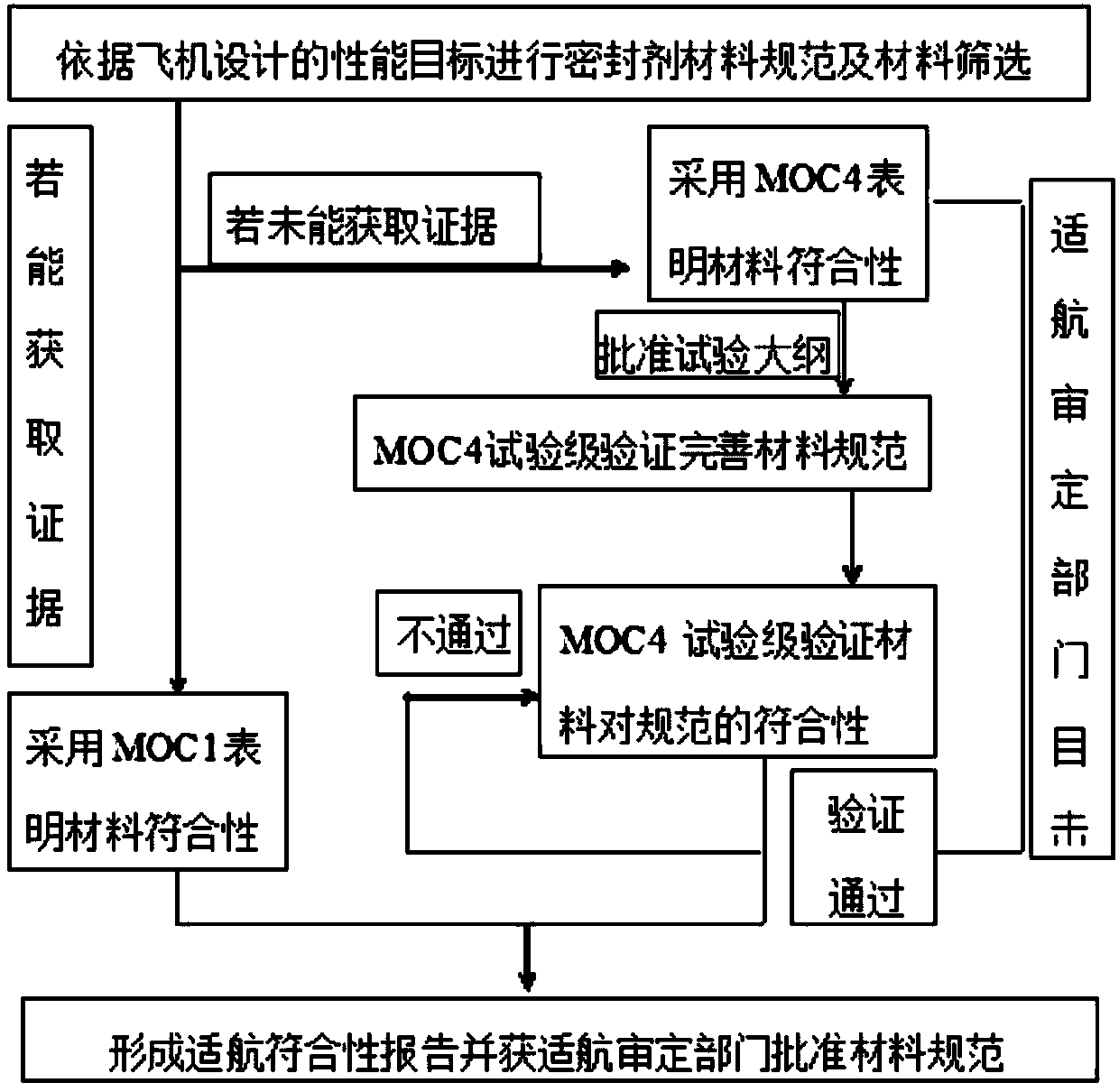

[0022] A sealant material verification method for airworthiness certification is provided, which includes the following steps:

[0023] Step 1, screen and select sealant materials according to the performance goals of aircraft design, and preliminarily determine the material selection system for sealant materials;

[0024] Step 2, for the sealant material used in domestic civil aircraft, if it can be proved that the material has been used in a certain model, and the model has obtained the CAAC type certificate of China Civil Aviation, only the design description method is used to indicate the material Conformity, if the material is no longer tested and verified, all operations of this method will be terminated; if not consistent, step 3 will be used for verification;

[0025] Step 3. For sealant materials that cannot be demonstrated in step 2, use laboratory verification methods to demonstrate compliance. See steps 4-7 for details;

[0026] Step 4. According to the materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com