Positioning device with flexible structure and positioning method of positioning device

A positioning device and flexible structure technology, applied in the direction of positioning device, clamping, support, etc., can solve the problems of low precision, large surface area of finishing, low service life, etc., and achieve the effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

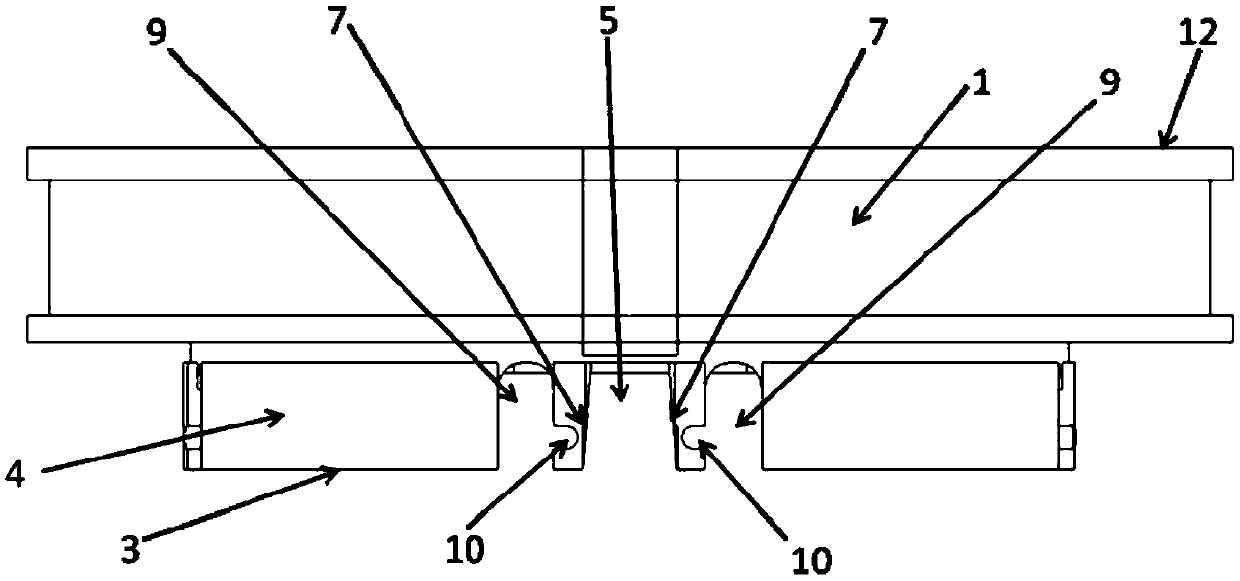

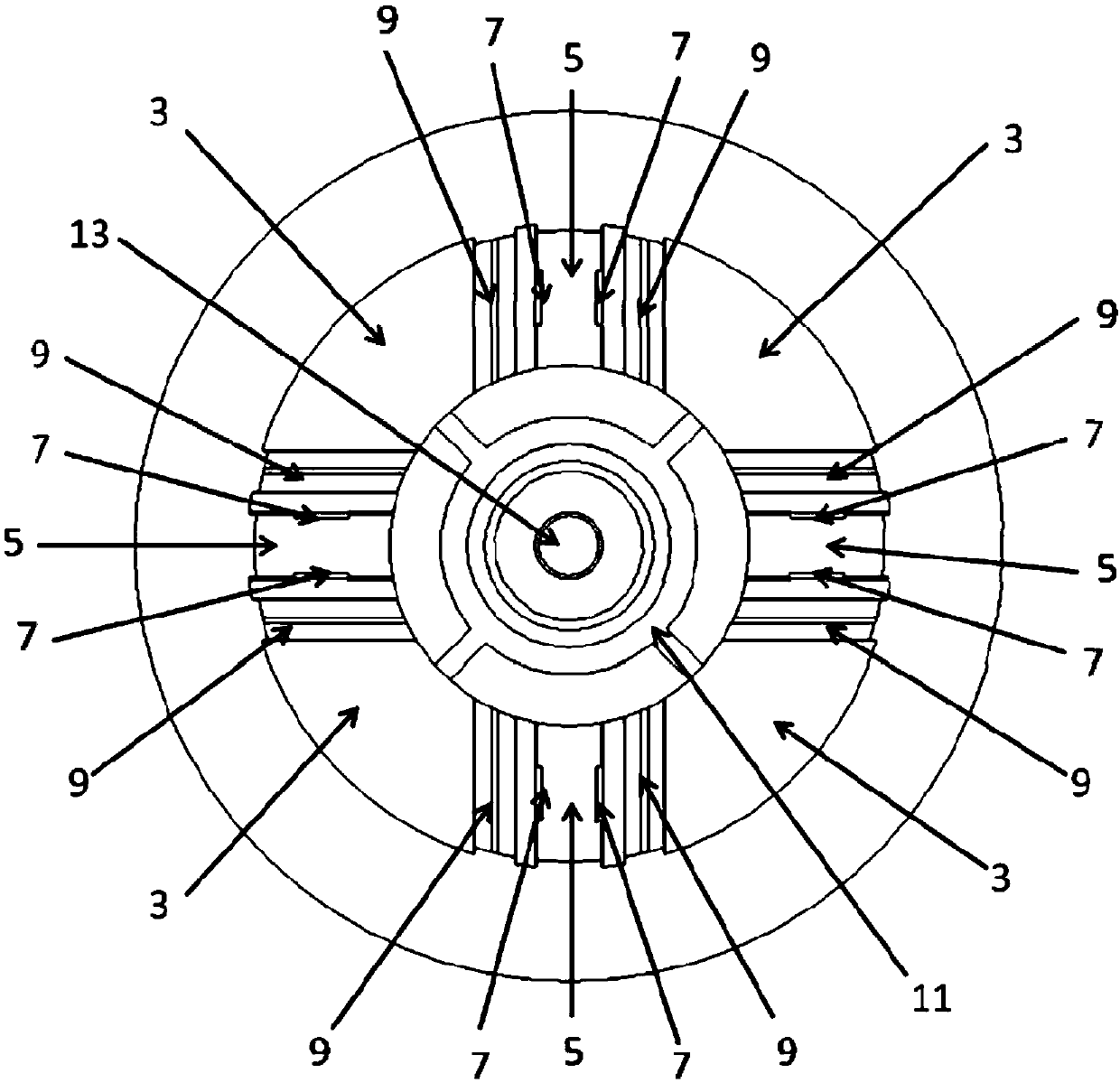

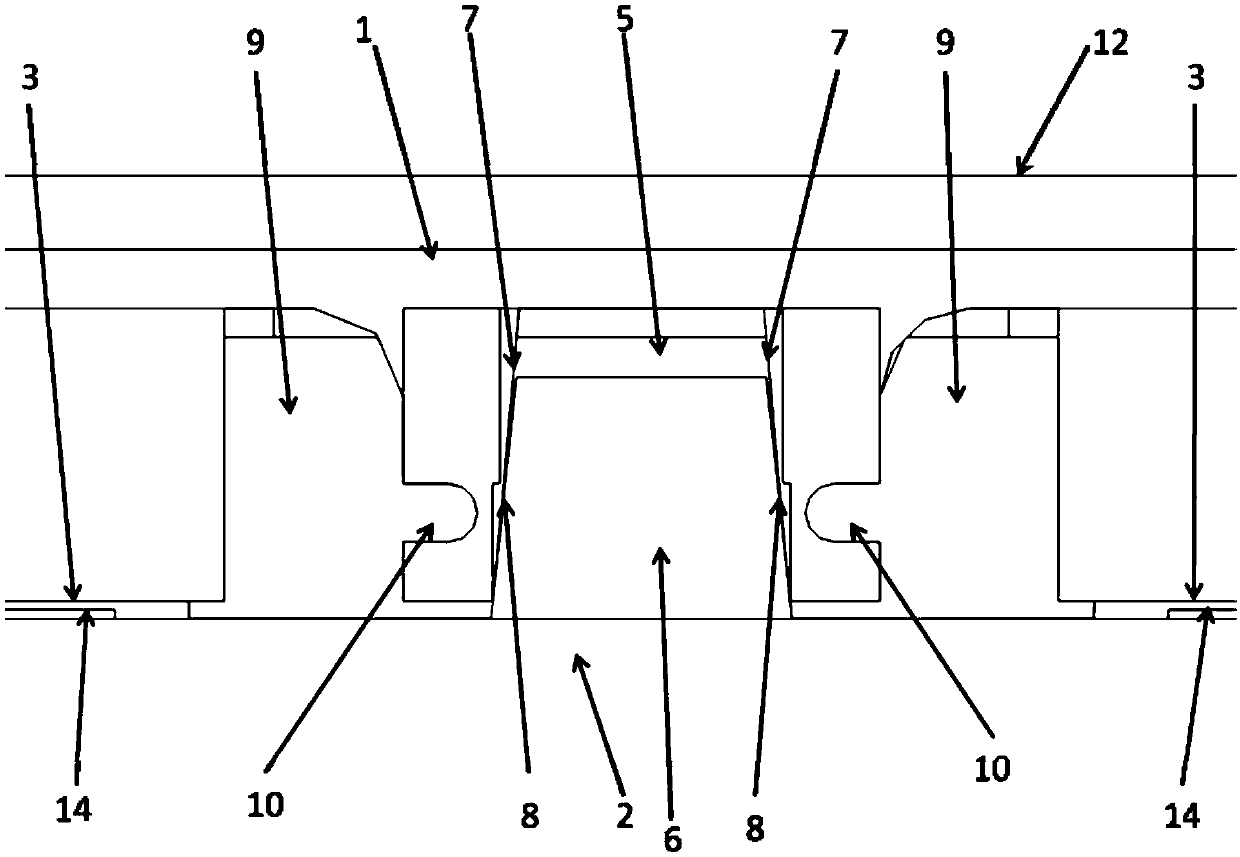

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] The present invention is a positioning device with a flexible structure and a positioning method thereof. The positioning device with a flexible structure is placed on a chuck; the positioning device with a flexible structure passes the groove edge of the positioning groove 5 and the positioning slope of the positioning tooth Contact; there is a small gap between the Z-direction positioning surface 3 of the positioning device with a flexible structure and the Z-direction positioning surface of the chuck; a threaded through hole is opened in the middle of the positioning device with a flexible structure, and a puller is installed on the threaded through hole. Tighten the nail with a tensioning device, and the positioning device moves toward the chuck until the Z-direction positioning surface of the chuck closely fits with the Z-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com