Method for replacing blind hole positioning pin of low-pressure turbine disc of aero-engine

An aero-engine and low-pressure turbine technology, applied in the mechanical field, can solve problems such as sinking, inner wall damage, and hole diameter expansion, and achieve the effects of improving the processing success rate, saving production costs, and increasing chip removal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

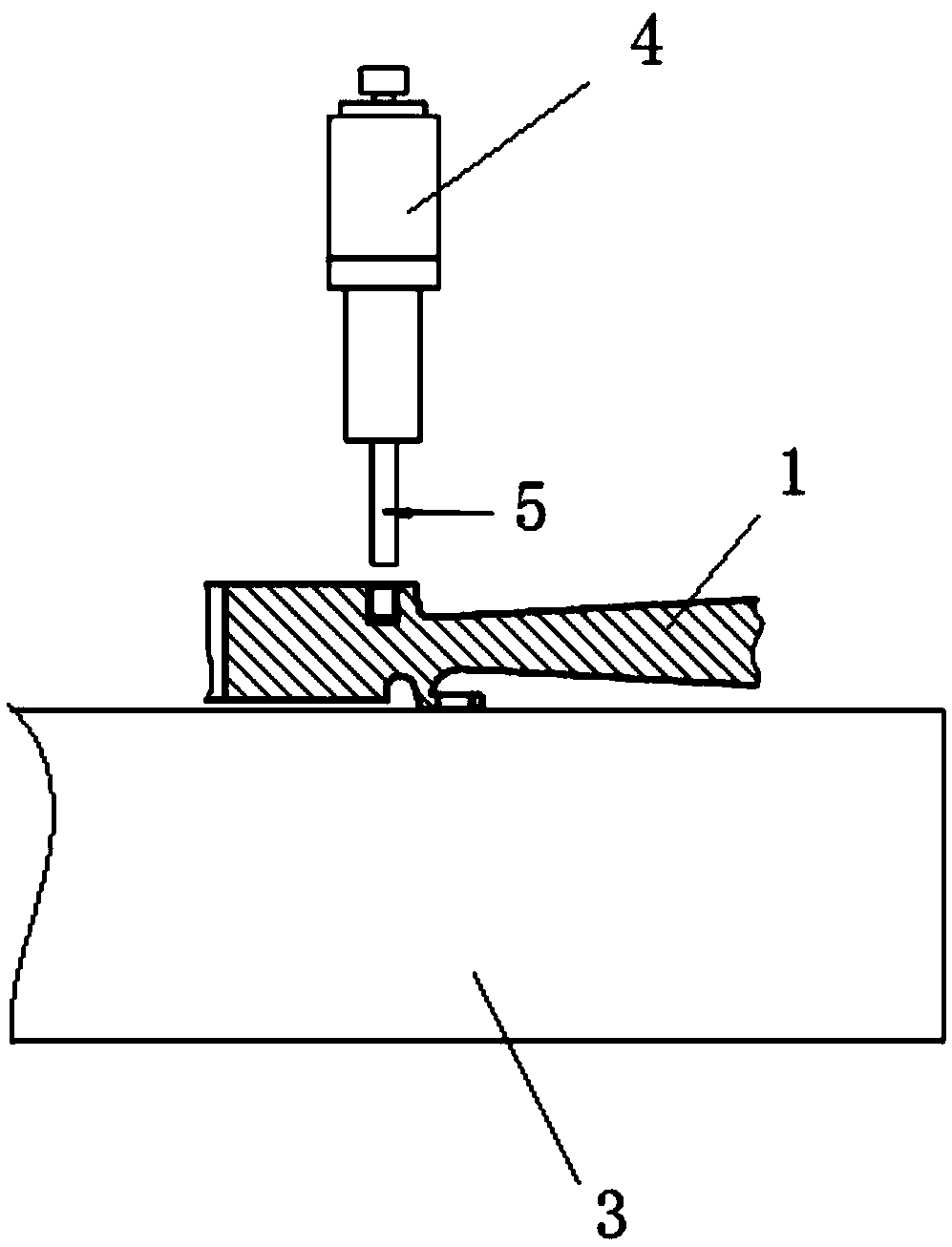

[0020] A method for replacing a blind hole positioning pin of an aero-engine low-pressure turbine disc, comprising the following steps:

[0021] 1) Boring processing to remove the protruding part of the positioning pin 2; process parameters: equipment: TK4100 / 2, coolant: castor oil, revolution: 400r / min, feed: 0.04mm / r;

[0022] 2) The fitter makes a positioning hole on the positioning pin 2;

[0023] 3) if figure 2 As shown, use a Φ4.2 drill bit 5 to drill a hole on the positioning pin 2;

[0024] 4) if image 3 , 4 As shown, the remaining positioning pins are removed by using a Φ4.5 milling cutter 6; the milling cutter 6 is a specially-made modified milling cutter, and a 4-blade center-blade milling cutter with a small chip chamber is selected. The second relief angle and the third relief The angle of the corner is increased by 3-5° by changing the grinding; install the milling cutter 6 on the radial drill 3, the process parameters: equipment: Z3063×20 / 1, coolant: casto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com