Anti-aging repair product for female reproductive system and preparation method of anti-aging repair product

A reproductive system and female technology, applied in the field of biomedicine, can solve the problems of increased incidence of cancer, increased activity of cancer-inducing genes, and insufficient attention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

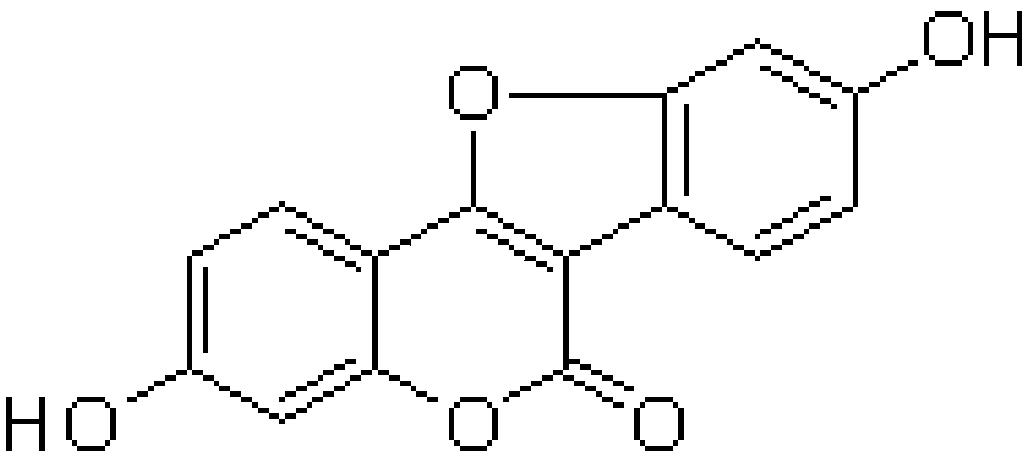

[0023] An anti-aging repair product for female reproductive system and its preparation method, 1. Dissolve 1g of sodium hyaluronate with suitable purified water; 2. Add 10g of hydrolyzed collagen to the sodium hyaluronate solution; 3. Add 100g more Glycerin, mix well; 4. In addition, use 50g of pentanediol to disperse 15g of hydroxyethyl cellulose; 5. Add the sodium hyaluronate mixture solution to the hydroxyethyl cellulose dispersion system, stir and thicken in a water bath at 60°C; 6. After the viscosity of the system increases, add 5g vitamin E, 50g turmeric and 10g couestrol, stir and mix evenly, and increase the homogenization operation according to the actual situation; 7. Adjust the pH of the system to 3.8-4.5 with lactic acid and sodium lactate; 8. Use purification Replenish the system with water to 1kg; 9. It can be sterilized by high temperature or add a suitable amount of preservatives, and 1kg of gel product is obtained.

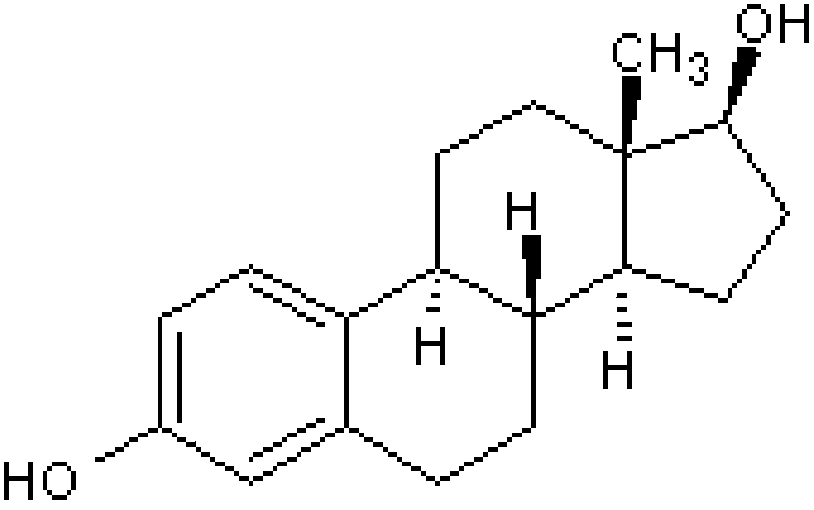

[0024] Evaluation of estrogen-like effects of...

Embodiment 2

[0036] An anti-aging and repairing foam product for the reproductive system and its preparation method. The product components include mass concentrations of couestrol 0.1%, vitamin E 0.5%, zedoary 5%, HA 0.1%, collagen 1%, foaming agent , GTCC and cetostearyl alcohol and other oils and emulsifiers.

[0037] Separately prepare the oil-soluble and water-soluble components in the raw materials, and then stir and dissolve them at 80°C. When the water phase and oil phase raw materials are stable at 80°C, slowly add the water phase to the oil phase. Stir at 80℃ for 5-10min, and then fully emulsify the mixture solution. After emulsification, stir the solution at 40℃ for 15-20min, add appropriate amount of preservative as needed and then pressurize filling, or after high temperature sterilization of the material liquid Carry out aseptic pressurized filling to obtain finished products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com