Preparation method of green apple flavor beverage

A technology of green apples and beverages, applied in dairy products, food ingredients, milk preparations, etc., can solve the problems of loss of nutrients, indigestion of nutrients, and reduction of nutritional value, so as to avoid loss of nutrients and reduce toxicity The production of substances, the effect of improving nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

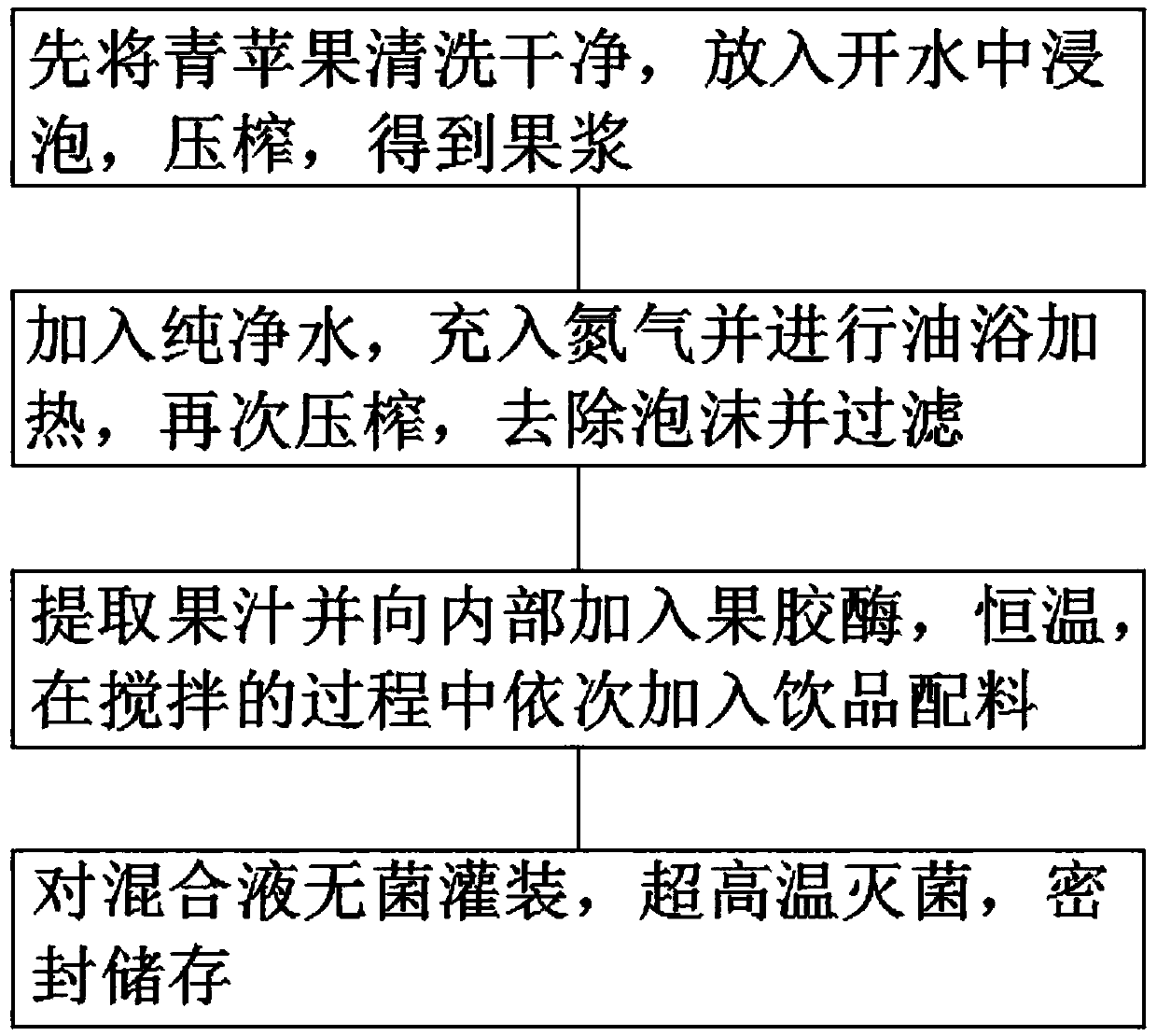

[0025] Such as figure 1 shown, including the following steps:

[0026] (1), first clean the green apples, soak them in boiling water, and squeeze them to obtain fruit pulp. The temperature of the boiling water is 98°C, and the soaking time is 12s. Before squeezing, the apples are peeled and cored;

[0027] (2), add pure water to pulp, fill with nitrogen and carry out oil bath heating, press again, remove foam and filter, filter: select 8 layers of 200 order nylon nets for use, obtain fruit juice, by weight, every 90 parts of fruit juice Add 65 parts of pure water to the slurry, the nitrogen flow rate is 25L / min, the oil bath heating time is 25min, and the oil bath temperature is 125°C;

[0028] (3), extract fruit juice and add pectinase to the inside, extract 125 parts of fruit juice by weight, add 0.20 parts of pectinase, keep constant temperature, the constant temperature is 42 ℃, add beverage ingredients in turn during the stirring process, drink Ingredients, made of the ...

Embodiment 2

[0031] (1), first clean the green apples, soak them in boiling water, and squeeze them to obtain fruit pulp. The temperature of the boiling water is 98°C, and the soaking time is 12s. Before squeezing, the apples are peeled and cored;

[0032] (2), add pure water to pulp, fill with nitrogen and carry out oil bath heating, press again, remove foam and filter, filter: select 8 layers of 200 order nylon nets for use, obtain fruit juice, by weight, every 90 parts of fruit juice Add 65 parts of pure water to the slurry, the nitrogen flow rate is 25L / min, the oil bath heating time is 25min, and the oil bath temperature is 125°C;

[0033] (3), extract fruit juice and add pectinase to the inside, extract 125 parts of fruit juice by weight, add 0.20 parts of pectinase, keep constant temperature, the constant temperature is 42 ℃, add beverage ingredients in turn during the stirring process, drink Ingredients, made of the following components by weight: 225 parts of purified water, 90 pa...

Embodiment 3

[0036] Such as figure 1 shown, including the following steps:

[0037] (1), first clean the green apples, soak them in boiling water, and squeeze them to obtain fruit pulp. The temperature of the boiling water is 98°C, and the soaking time is 12s. Before squeezing, the apples are peeled and cored;

[0038] (2), add pure water to pulp, fill with nitrogen and carry out oil bath heating, press again, remove foam and filter, filter: select 8 layers of 200 order nylon nets for use, obtain fruit juice, by weight, every 90 parts of fruit juice Add 65 parts of pure water to the slurry, the nitrogen flow rate is 25L / min, the oil bath heating time is 25min, and the oil bath temperature is 125°C;

[0039] (3), extract fruit juice and add pectinase to the inside, extract 125 parts of fruit juice by weight, add 0.20 parts of pectinase, keep constant temperature, the constant temperature is 42 ℃, add beverage ingredients in turn during the stirring process, drink Ingredients, made of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com