Plastering machine automatic horizontal moving and walking control method and plastering robot

A technology of walking control and plastering machine, which is applied in the direction of construction and building structure, and can solve the problems of uneven plastering thickness, uneven wall surface, and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

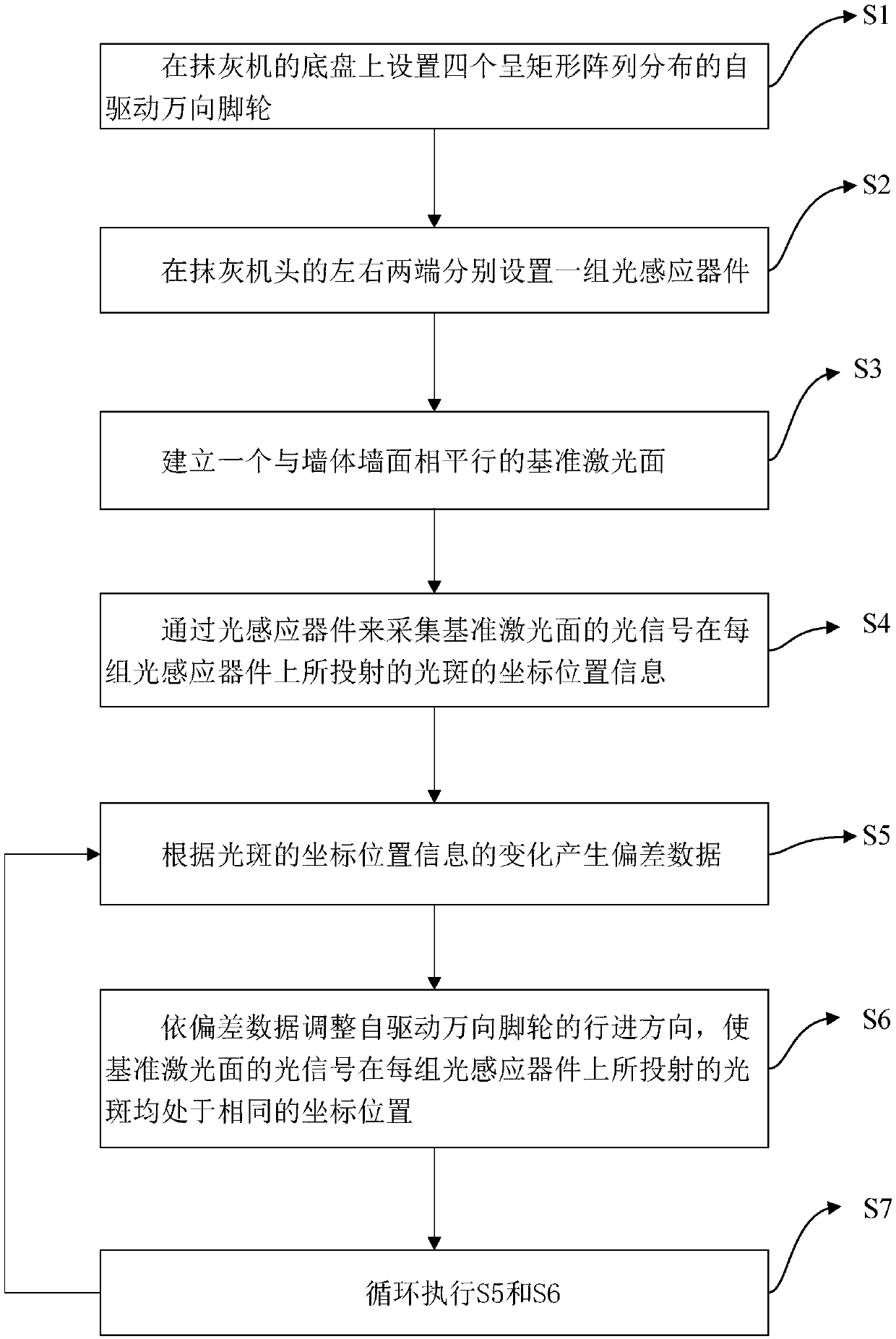

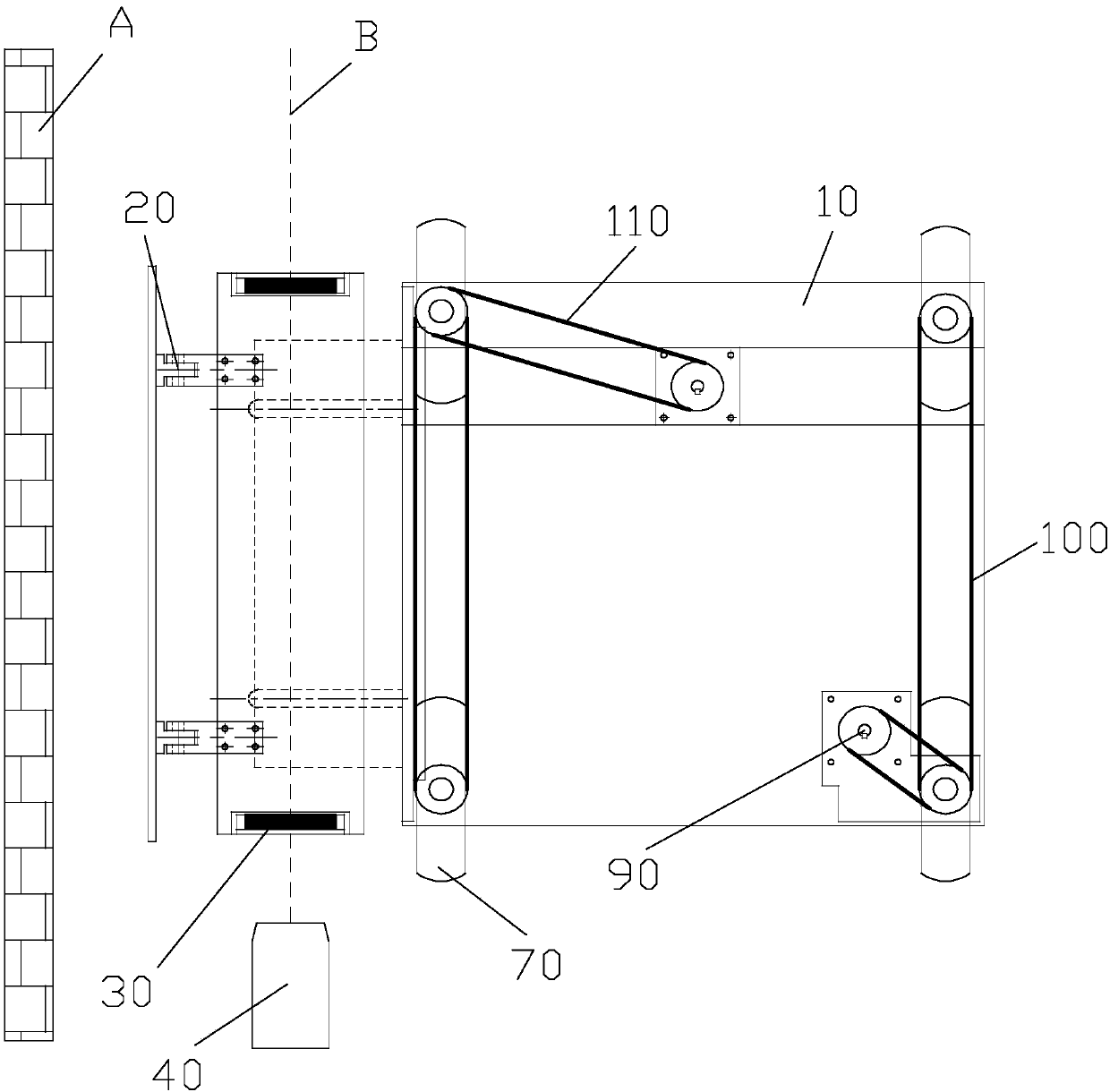

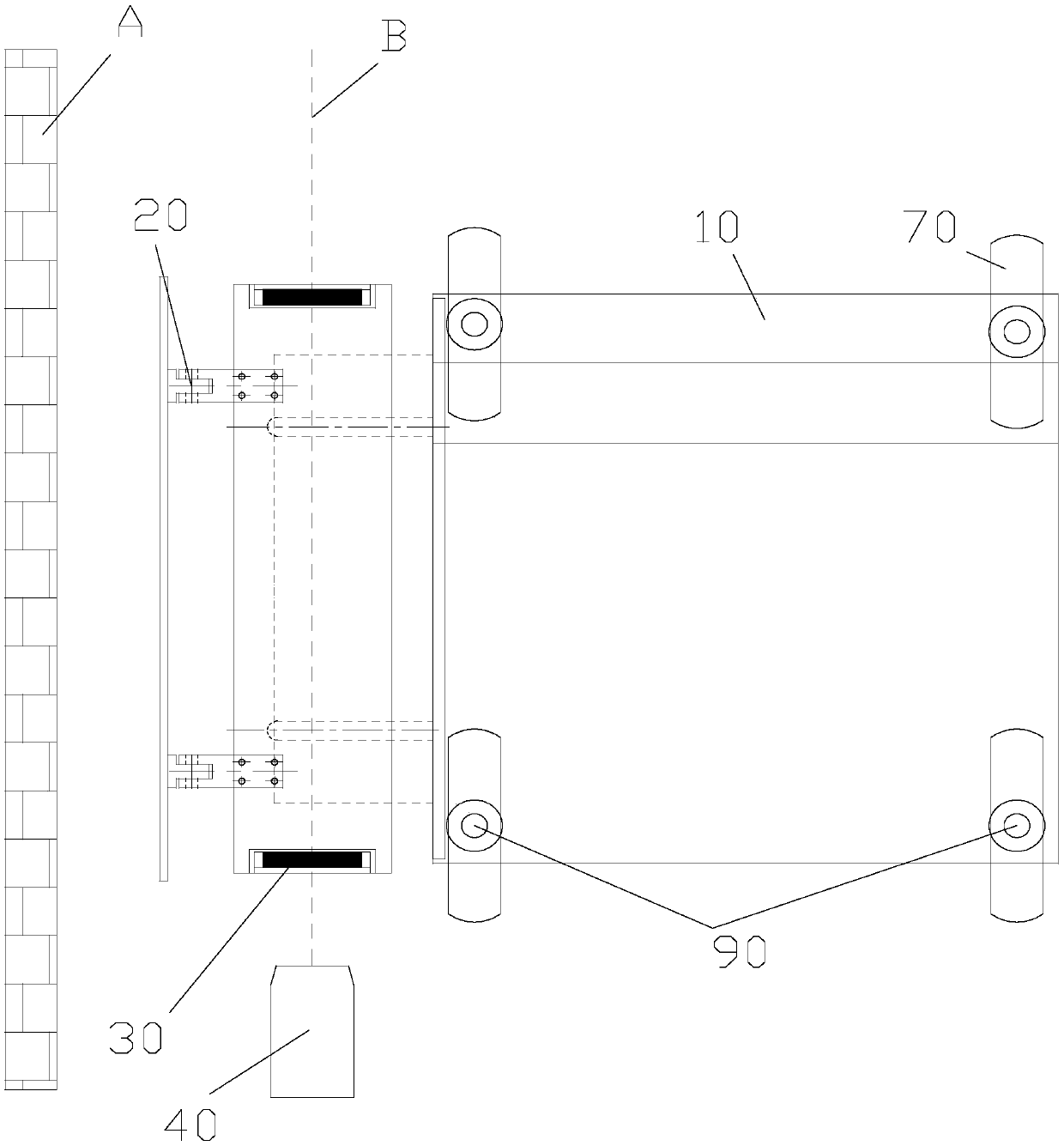

[0034] like Figure 1 to Figure 4 As shown, the present embodiment provides a plastering machine automatic translation walking control method, which includes the following steps:

[0035] S1. Set four self-driven universal casters in a rectangular array on the chassis 10 of the plastering machine to ensure that the connecting line between the center points of two adjacent self-driven universal casters is at the plastering distance with the plastering machine The front end face of the machine head 20 is parallel or in a plane perpendicular to it; the self-driven universal caster mentioned above means that the caster can move in a horizontal plane (that is, a plane parallel to the chassis 10 or the ground) under the action of the power control compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com