Ground connection wall joint leakage monitoring repair device and method based on optical fiber temperature measuring

A technology of optical fiber temperature measurement and ground connection wall, which is applied in the repair of basic structure, test of basic structure, basic structure engineering, etc. Safety risks, simple construction process, and highly targeted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

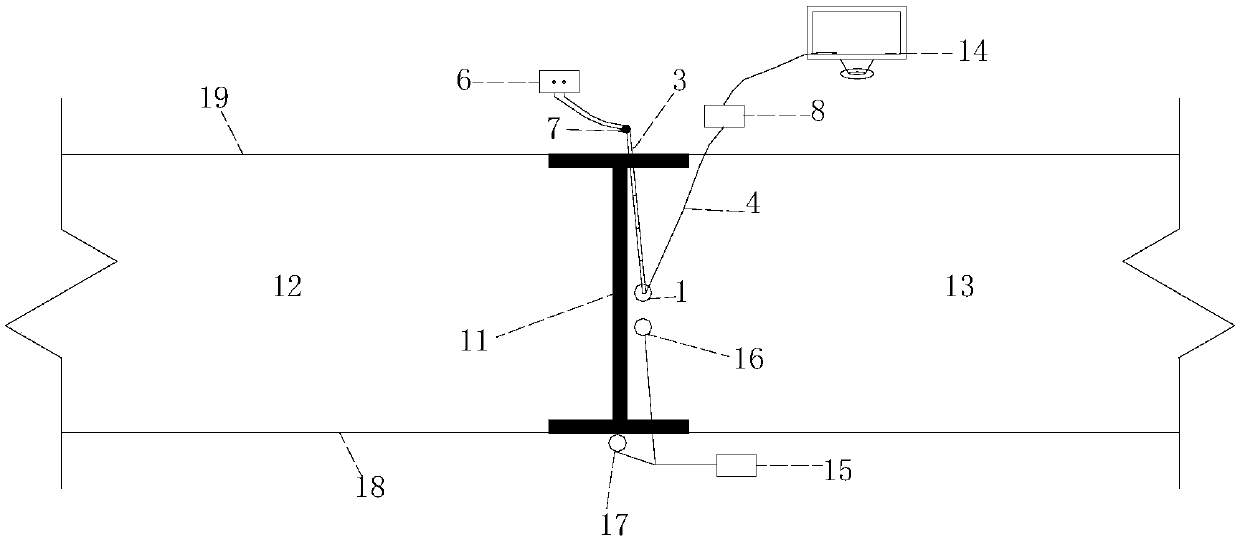

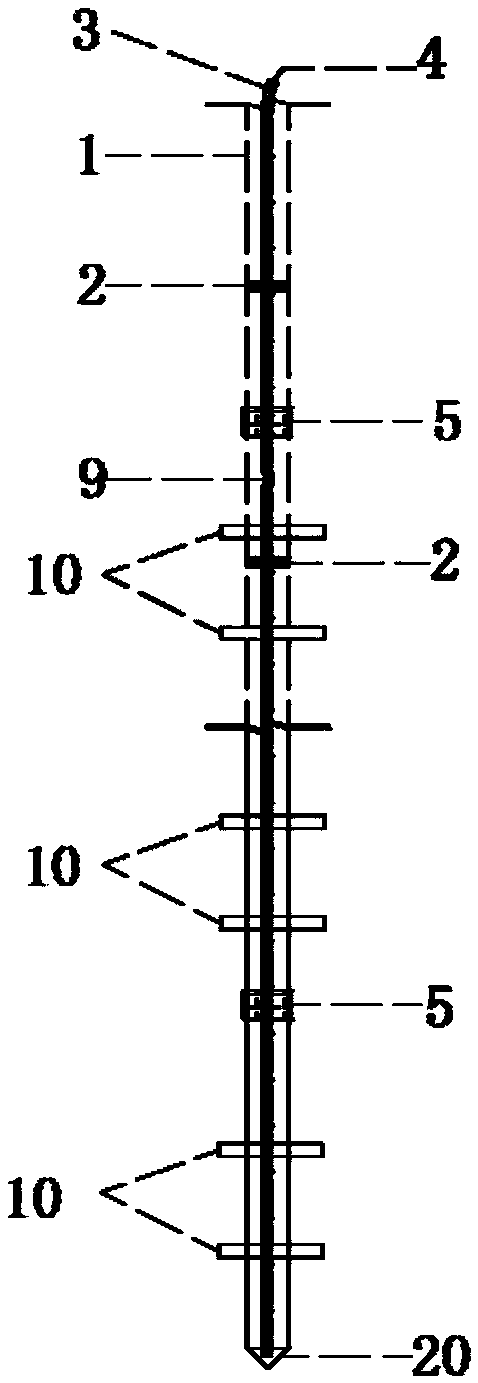

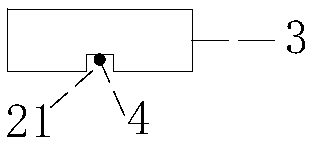

[0025] The ground connection wall joint leakage monitoring and repairing device based on optical fiber temperature measurement includes an I-shaped steel joint 11, and the grooves on both sides of the I-shaped steel joint 11 are respectively connected with the reinforcement cage of the leading groove section 12 of the underground diaphragm wall and the follow-up of the underground diaphragm wall. The steel cage connection of the groove section 13, the connection seam of the underground diaphragm wall is formed between the leading groove section 12 of the underground diaphragm wall and the subsequent groove section 13 of the underground diaphragm wall, and the I-shaped steel joint 11 extends along the connection seam of the underground diaphragm wall. It is characterized in that, It includes a hollow floral tube 1, which extends along the connecting joint of the underground diaphragm wall. The hollow floral tube 1 is fixed in the groove of the I-shaped steel joint 11 facing the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com