Crucible disc mechanism with feeding device and operation method thereof

A technology of feeding device and crucible, which is applied to chemical instruments and methods, during the use of growth, the seed crystal remains in the molten liquid, crystal growth and other directions, which can solve the problems of time-consuming and labor-intensive operators and rely on manual operation, etc., to reduce the number of employees The effect of operation action, improvement of feeding efficiency, and convenient operation of employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

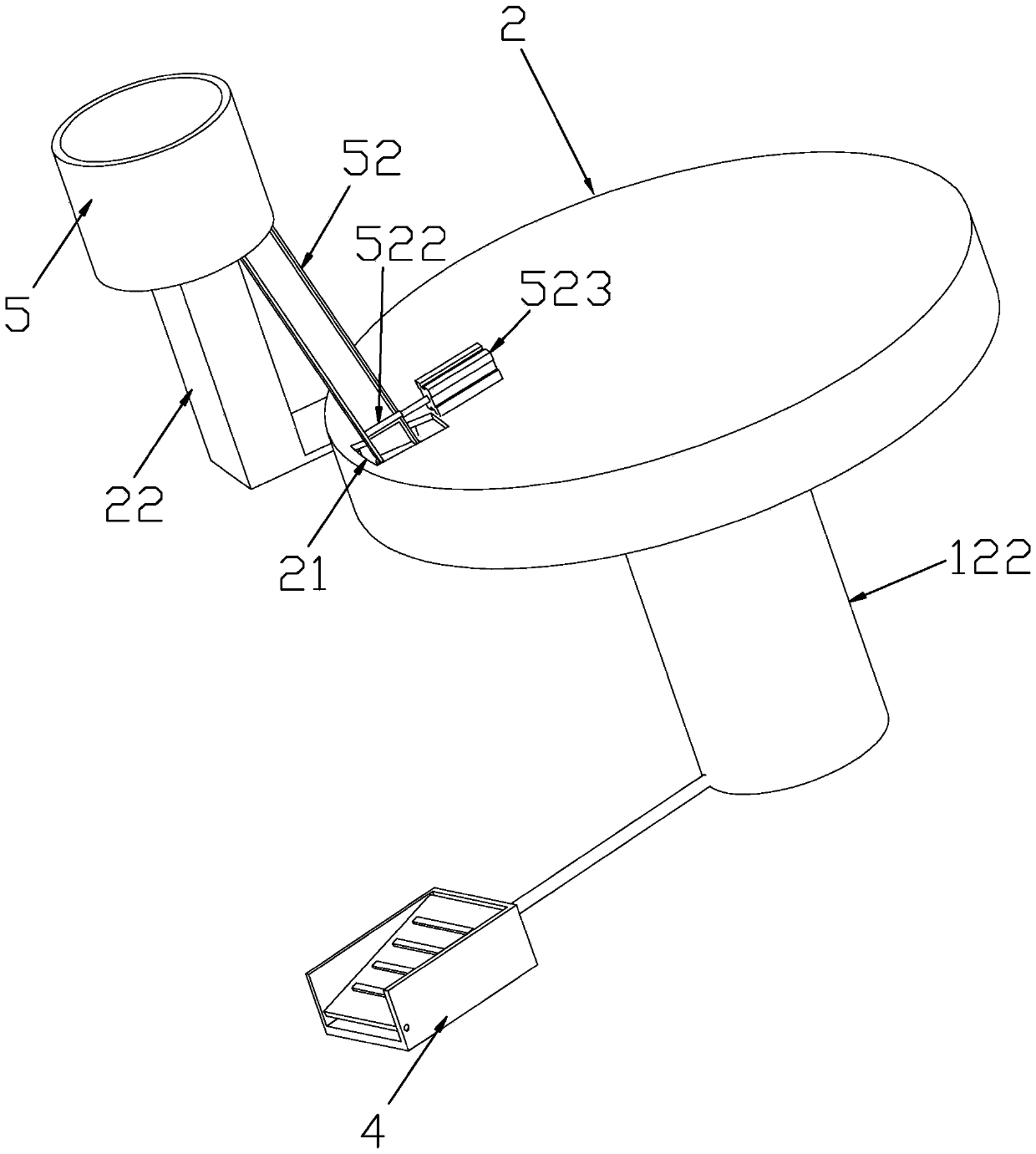

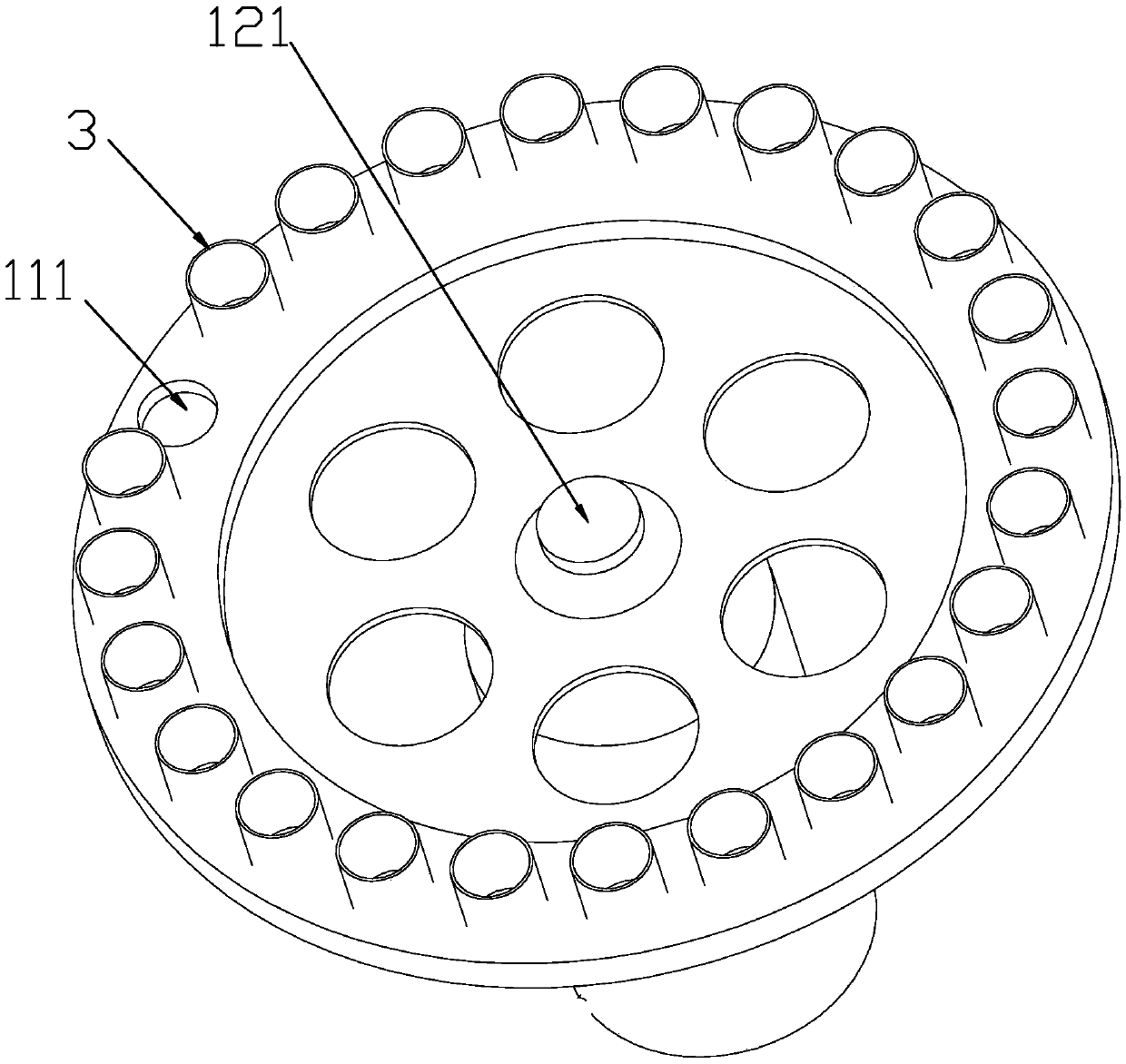

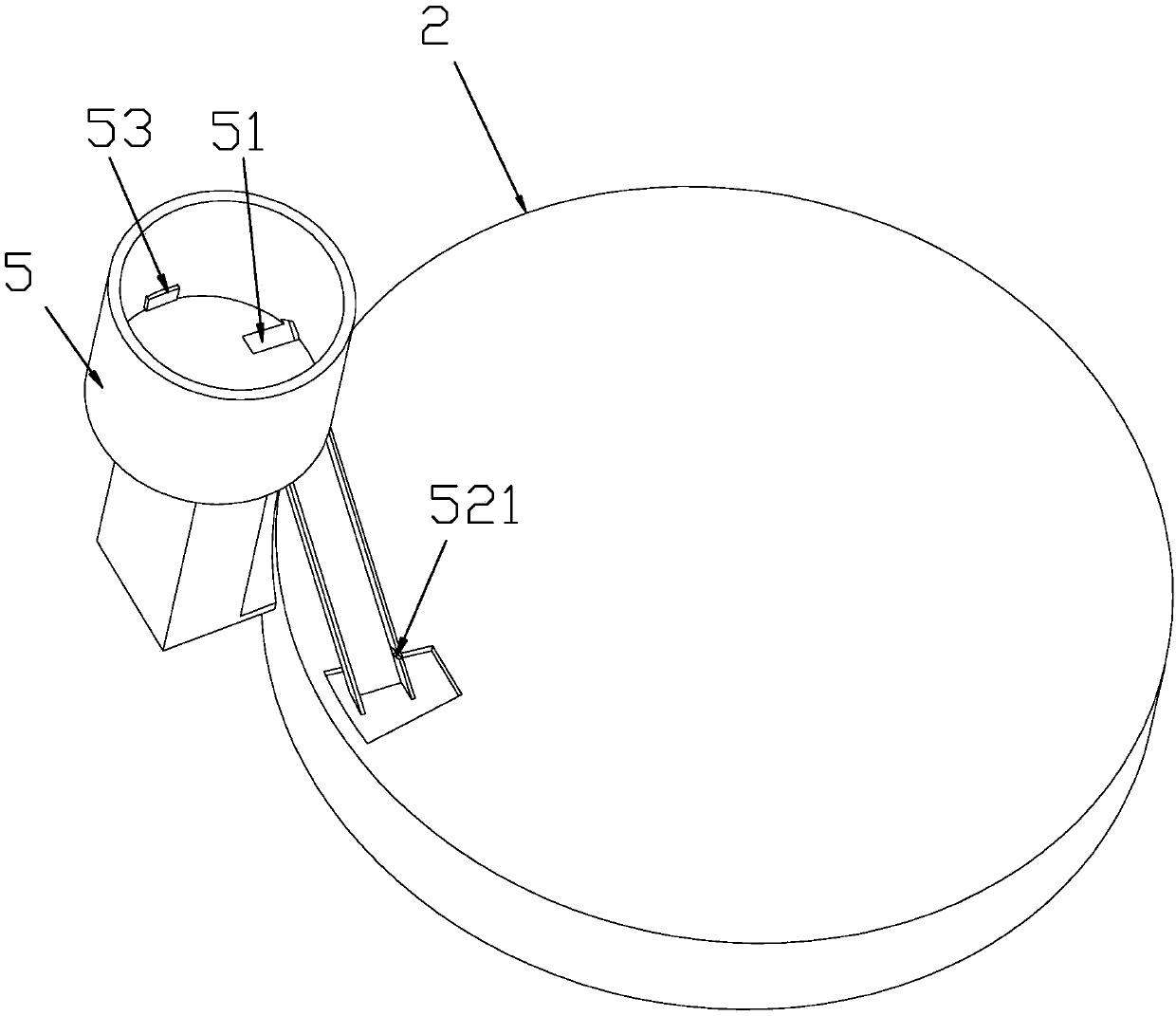

[0024] see Figure 1-Figure 3 As shown: a crucible plate mechanism with a feeding device, including a crucible plate 1, the crucible plate 1 includes a concentrically arranged accommodating plate and an outer plate, the outer plate is covered with a plate cover 2, and the accommodating plate is surrounded by 24 A crucible accommodating groove 111, a crucible 3 is arranged in the crucible accommodating groove 111, a driving shaft 121 arranged concentrically with the outer disk is provided in the middle of the outer disk, a driving motor 122 is arranged at one end of the driving shaft 121, and the disk cover 2 is accommodated in one of the crucibles A feeding port 21 is provided at the corresponding position of the groove 111, and the outer wall of the disc cover 2 is provided with a feeding device close to the feeding port 21, which can feed the crucible 3 exposed to the feeding port 21 on the crucible plate 1, and the driving motor 122 is connected with a foot pedal Switch 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com