A fully automatic indentation coding machine

A fully automatic, coding machine technology, applied in stamping, printing, etc., can solve problems such as low degree of automation, manual coding misoperation, coding errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

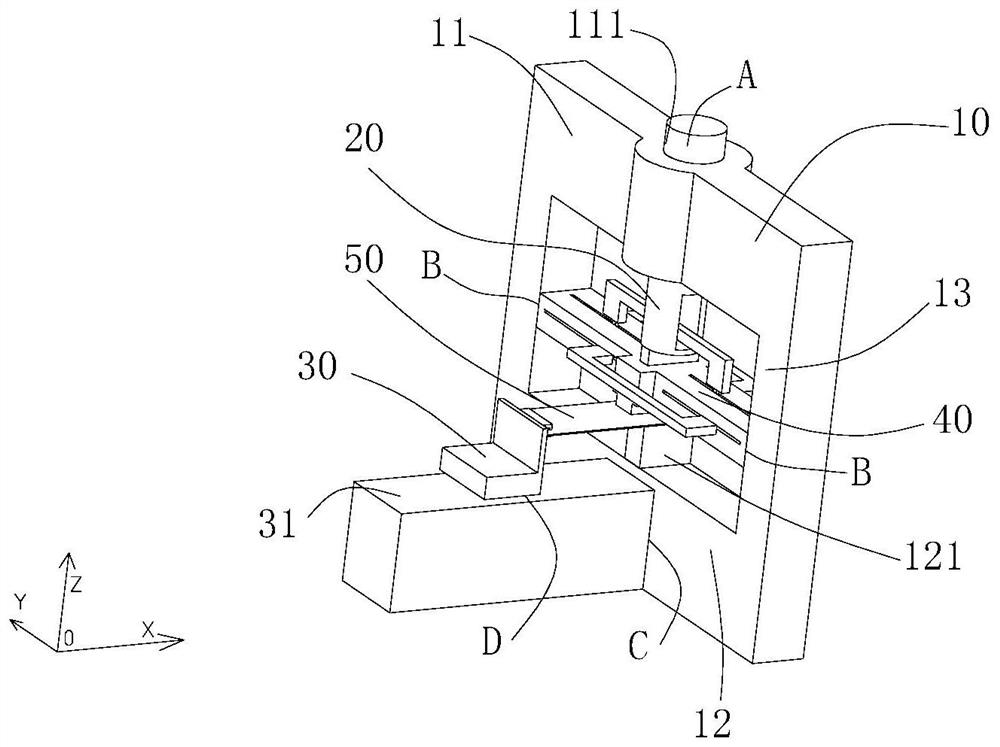

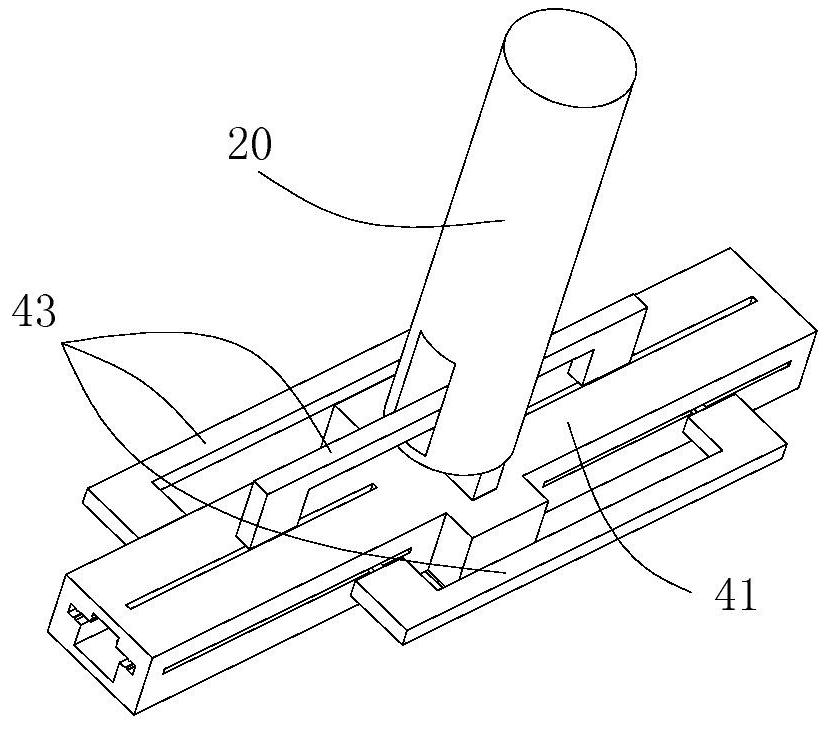

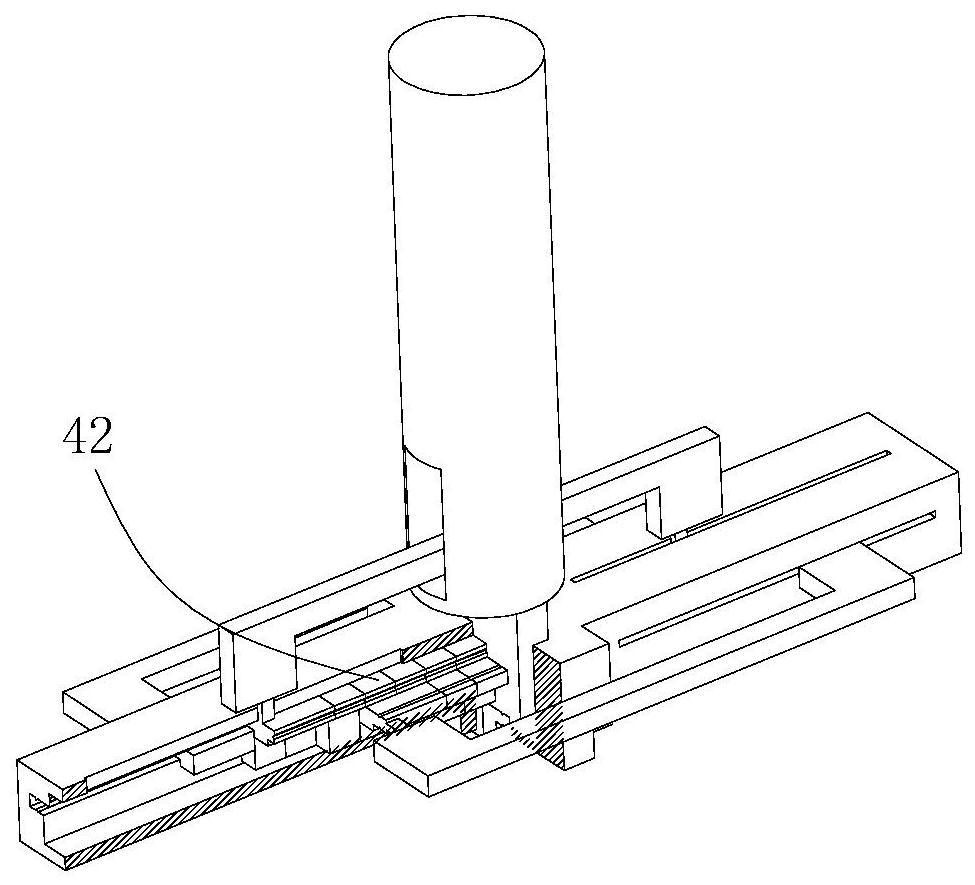

[0047] Such as figure 1 As shown, a fully automatic indentation coding machine includes a frame 10 , a striking head 20 , a feeding clamp 30 and a fully automatic coding punch 40 .

[0048] The frame is back-shaped and includes a top plate 11, a base 12 and two side plates 13 connecting the top plate and the base.

[0049] Wherein, the lifting guide hole 111 is preferably provided in the middle of the top plate, and the pad iron 121 is preferably provided in the center of the base for supporting the metal workpiece 50 .

[0050] The top of the blow head and the center of the top plate are at figure 1 Sliding connection at middle A, the height of the striking head can be raised and lowered. preferred, such as Image 6 As shown, the top of the striking head is a lifting column 21, which slides and fits with the above-menti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com