Precise pressing control method for ceramic brick press

A technology of ceramic tile press and control method, which is applied in the direction of ceramic molding machines, manufacturing tools, auxiliary molding equipment, etc., and can solve problems such as difficult maintenance of equipment, unsuitability for modern ceramic tile manufacturing needs, and large dependence of on-site personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

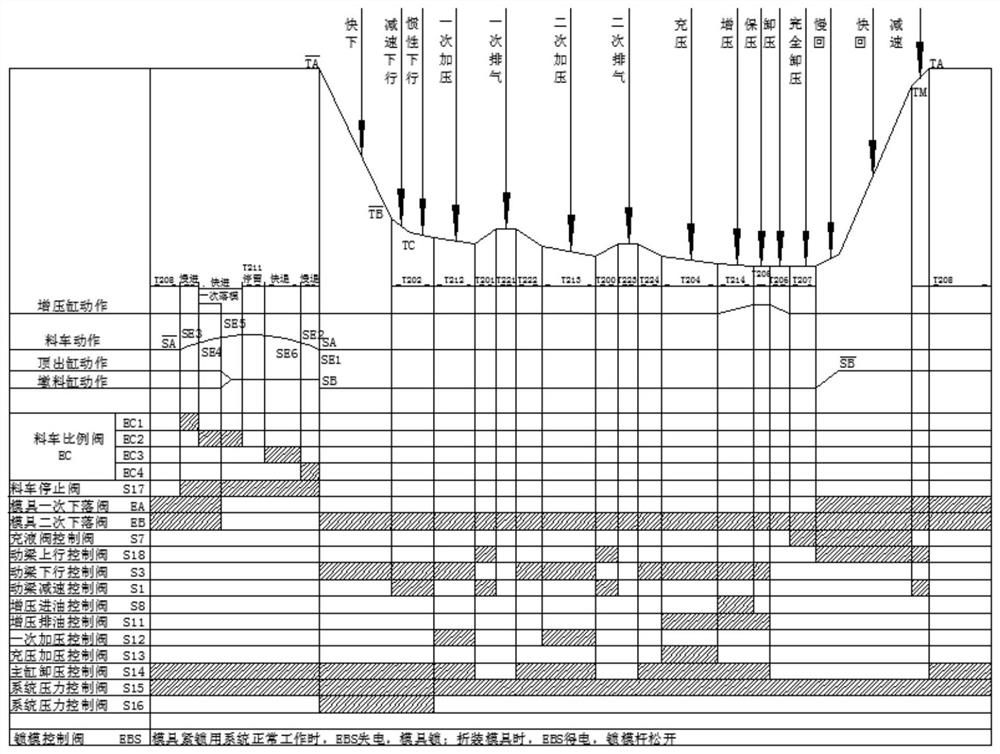

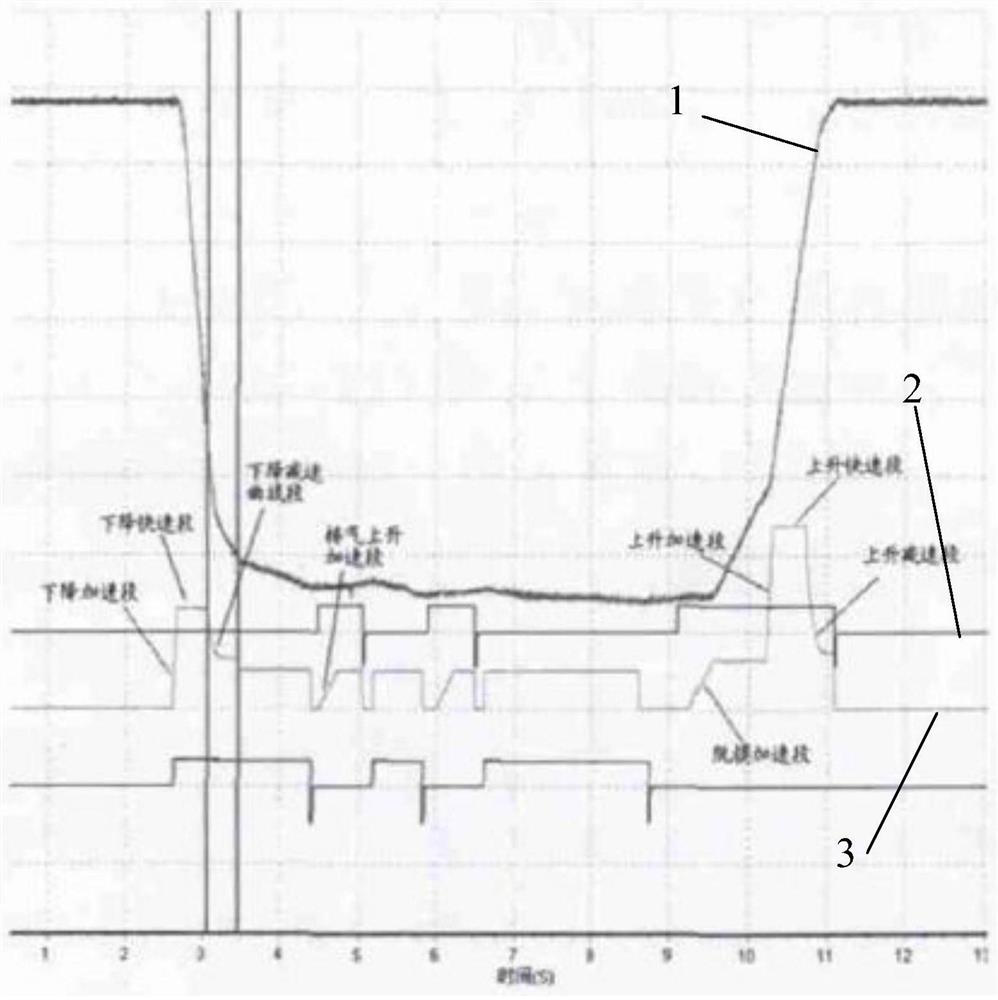

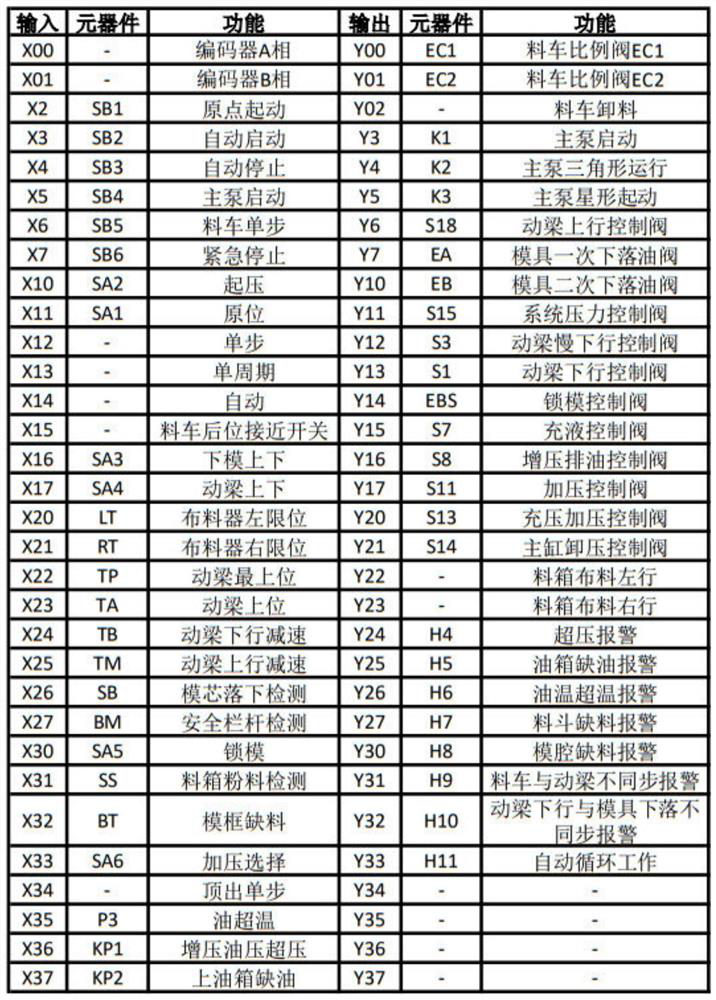

[0031] The present invention discloses a precision pressing control method for a ceramic tile press. Firstly, it realizes remote control of the tile press by introducing a programmable logic controller (PLC) and a secondary network connection into the tile press. The public patent document CN103412524A constructs a set of digital production management system for brick-making enterprises based on network connection, which can remotely control the brick-making factory equipment through the remote network by the central industrial computer, which can effectively solve the current manufacturing equipment and technology. Large, and at the same time, equipment maintenance is also more difficult. For the control of the brick press, it can also build a network connection, send the PLC program of the tile pressing process to the brick press fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com