Drilling device for automobile engine hood

A technology of engine cover and drilling device, applied in positioning device, clamping device, boring/drilling and other directions, can solve the deformation of automobile engine cover, affecting the accuracy of drilling, assembly, and insufficient clamping, etc. problem, to achieve the effect of convenient drilling operation, reducing scrap rate and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

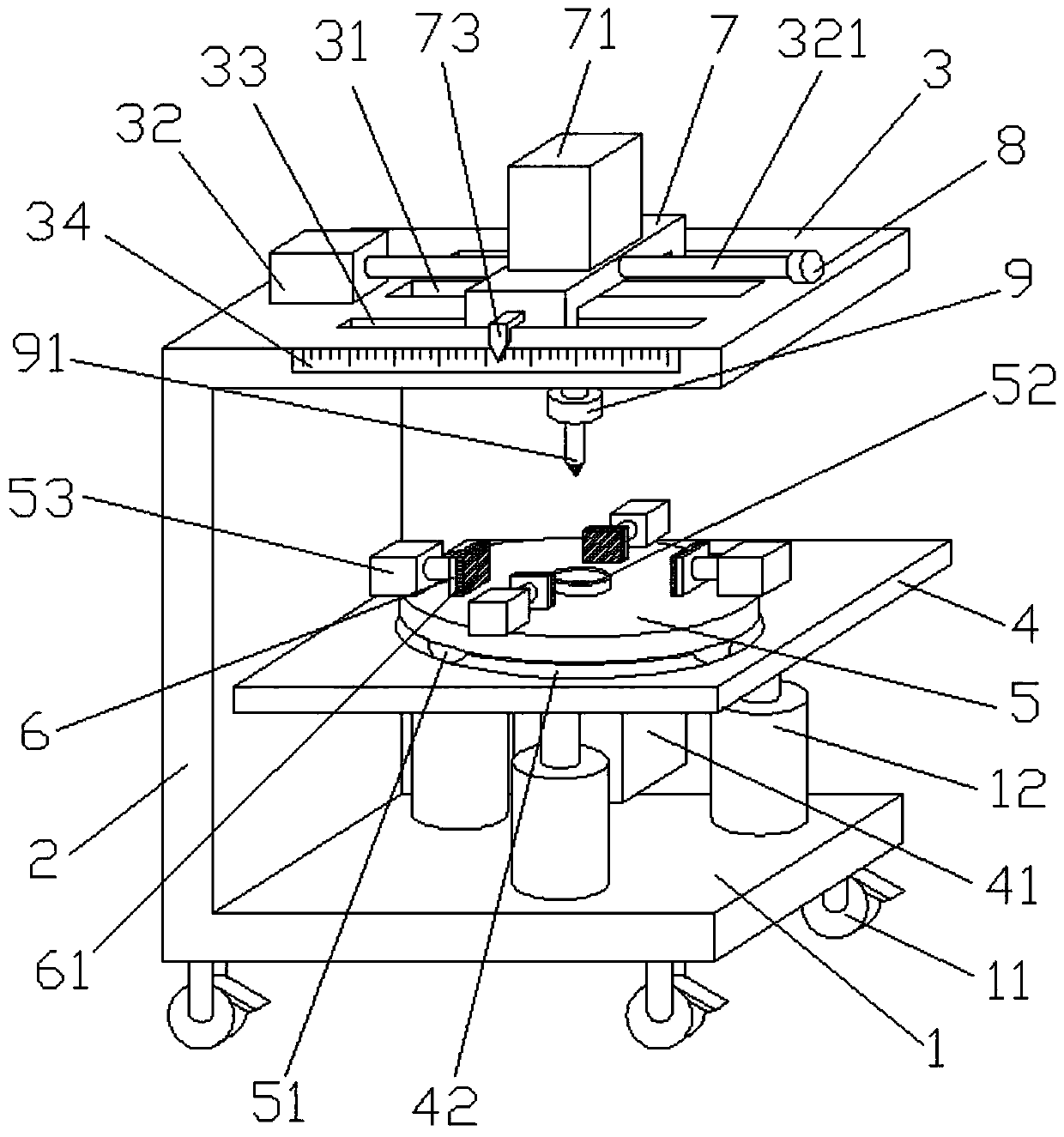

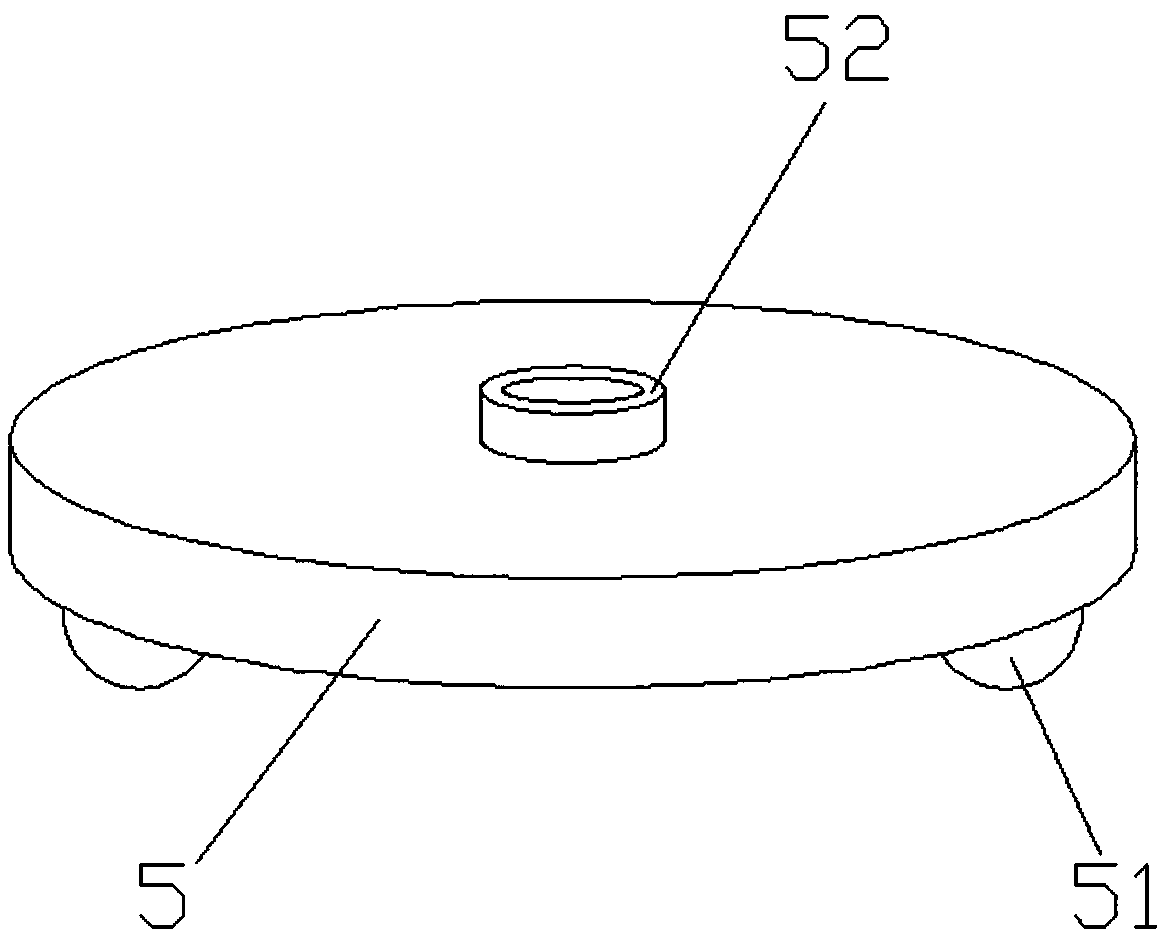

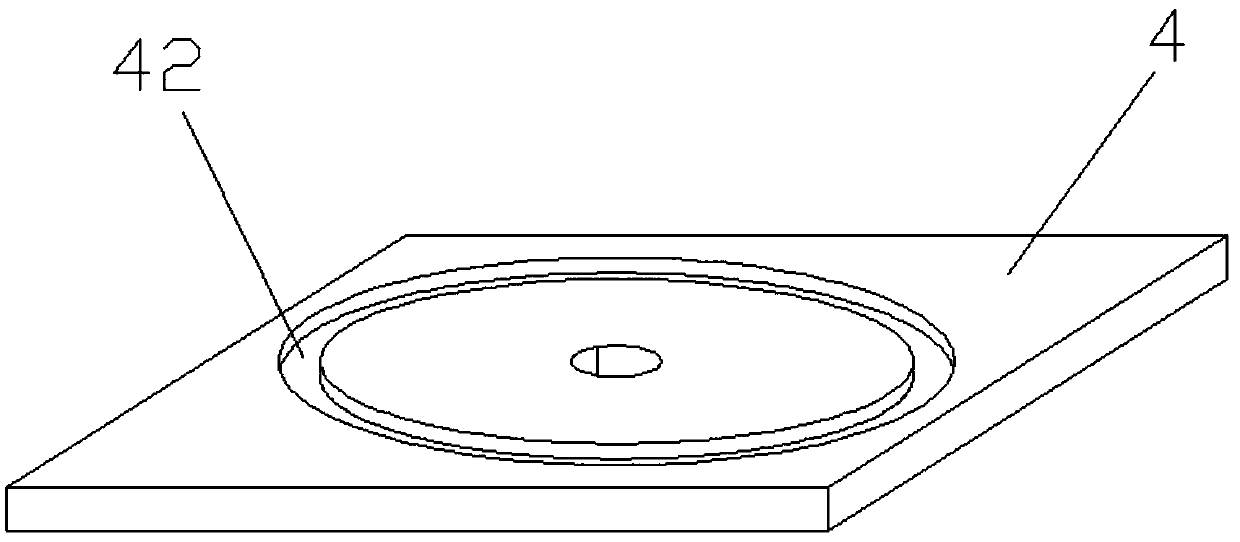

[0023] Embodiment 1 discloses a kind of drilling device that is used for automobile engine cover, as figure 1 As shown, it includes a bottom plate 1, a riser 2 and a top plate 3, the bottom of the riser 2 is vertically connected to the end of the bottom plate 1, the top of the riser 2 is vertically connected to the end of the top plate 3; the four corners of the bottom of the bottom plate 1 All are fixedly installed with rollers 11, the rollers 11 are brake universal wheels, and the brake universal wheels are equipped with vehicle-related devices, which can position the automobile engine compartment cover when the automobile engine compartment cover drilling device moves to an appropriate position. There are three lift cylinders 12 fixedly installed on the top of 1. The model of lift cylinder 12 is CDQ2B12-20DMZ. The cross-section between the three lift cylinders 12 is an equilateral triangle. The ends are fixedly connected, and the middle part of the bottom end of the lifting...

Embodiment 2

[0027] Embodiment 2 discloses a drilling device for an automobile engine compartment cover, comprising a base plate 1, a riser 2 and a top plate 3, the bottom of the riser 2 is vertically connected to the end of the base plate 1, and the top of the riser 2 is connected to the top of the riser 2. The ends of the top plate 3 are vertically connected; the four corners at the bottom of the bottom plate 1 are fixedly equipped with rollers 11, and the rollers 11 are brake universal wheels. When moving to an appropriate position, the engine compartment cover of the automobile is positioned. Four lifting cylinders 12 are fixedly installed on the top of the bottom plate 1. The model of the lifting cylinder 12 is CDQ2B12-20DMZ. Four corners, the end of the piston rod of the lifting cylinder 12 is fixedly connected with the bottom of the lifting plate 4, and the middle part of the bottom of the lifting plate 4 is fixedly installed with a first motor 41. The model of the first motor 41 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com