A fire water gun quickly assembled by using multi-stage clamping positions

A fast and fire-fighting technology, applied in fire rescue and other directions, can solve problems such as affecting fire-fighting work, time-consuming, separation of water guns and water belts, etc., to achieve the effect of improving the firmness of installation, increasing the speed of the card position, and increasing the speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0030] Such as Figure 1-Figure 5 As shown, the present invention provides a technical solution for quickly assembling a fire-fighting water gun using multi-stage clamping positions:

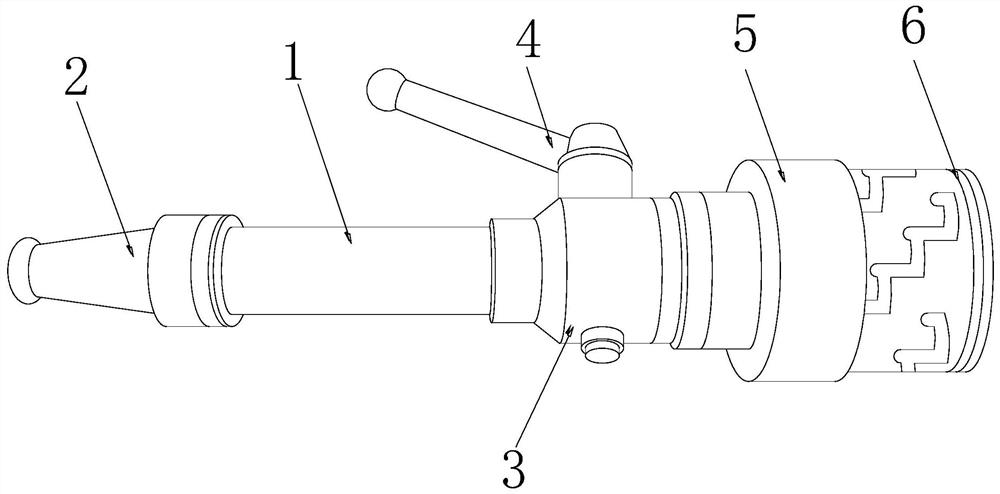

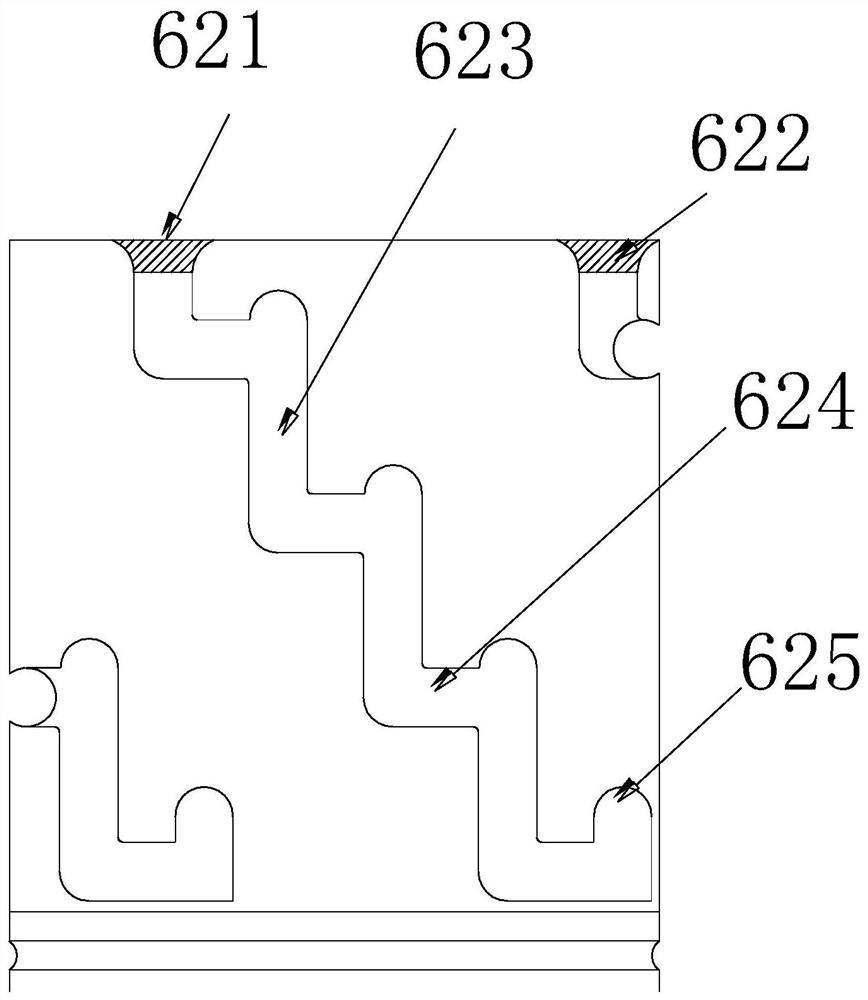

[0031] A fire-fighting water gun that utilizes multi-stage snap-in fast assembly, and its structure includes a gun body 1, a nozzle 2, a valve 3, a control valve handle 4, a connecting ring 5, and a quick-assembly snap-in structure 6, and the gun body 1 is cylindrical structure, the nozzle 2 is set at the front end of the gun body 1 and is connected by screw engagement, the valve 3 is set at the rear of the gun body 1 and is an integrally formed structure, the control valve handle 4 is set above the valve 3, and the connection The ring 5 is arranged at the rear end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com