Device and method for manufacturing multi-purpose partition wall

A multi-purpose planting trough technology, applied in the direction of automatic watering devices, botanical equipment and methods, applications, etc., can solve the problems of multiple vertical distances, threats to the lives of the masses, and unusable elevators, etc., to reduce the process and Cost, increase the overall appearance, improve the effect of survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

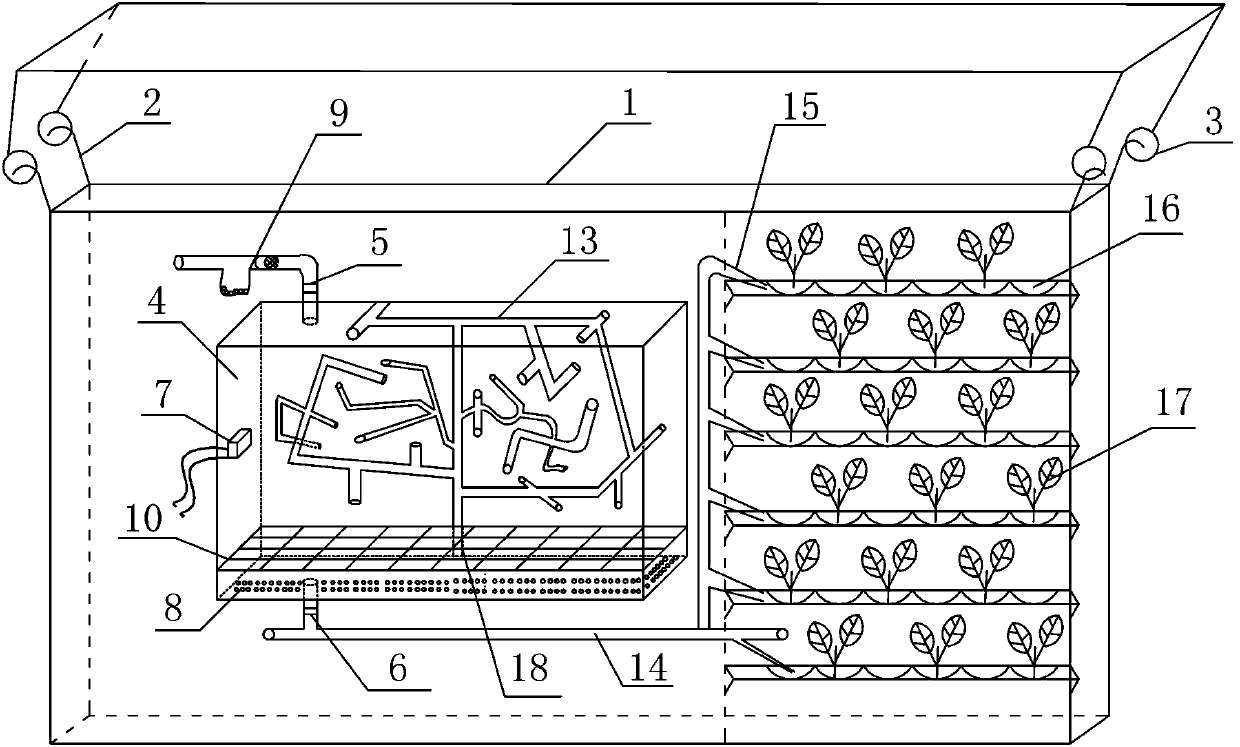

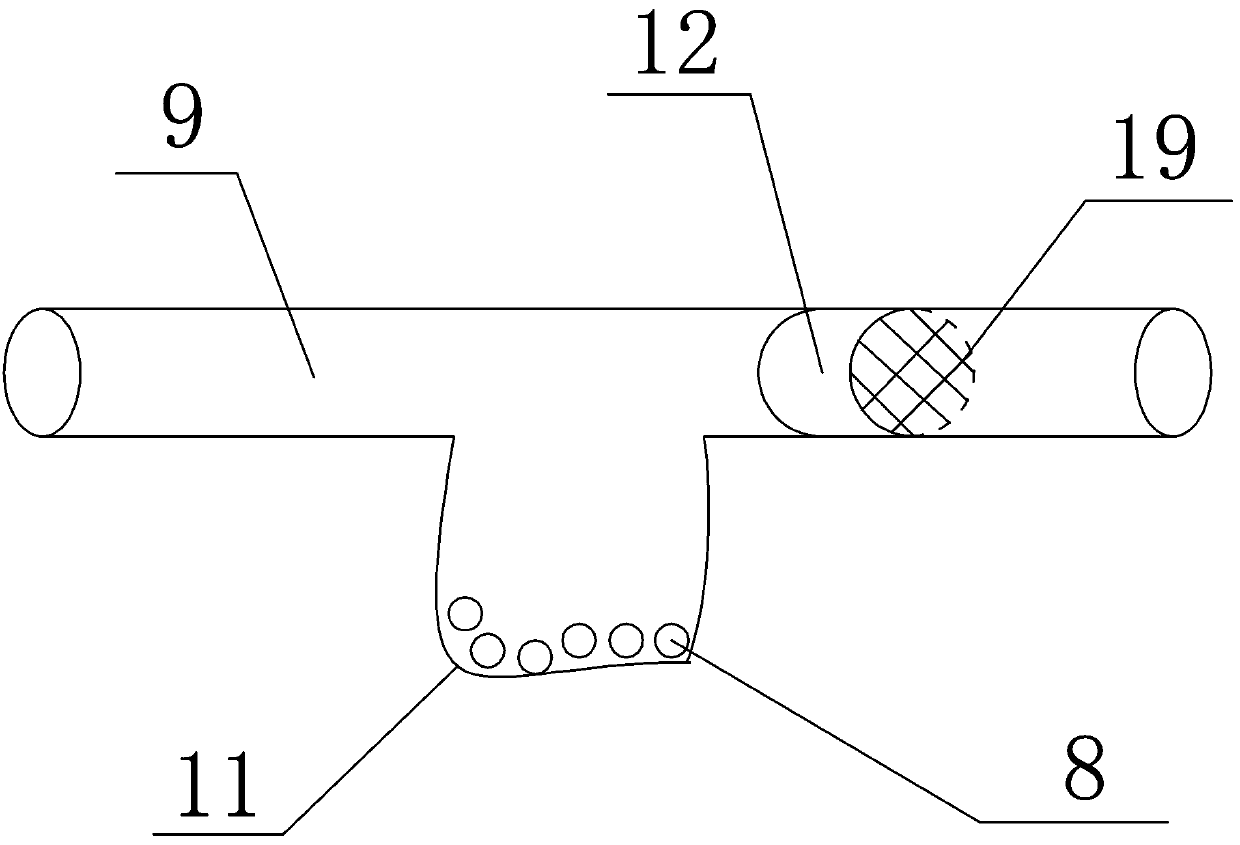

[0038] See Figure 1-2 , A device for making a multi-purpose partition wall, which includes a steel frame structure 1, and hooks 2 are fixedly arranged at the four top corners of the steel frame structure 1, and the hooks 2 are hooked on the wall frame through the hooks 3 On the beam of the structure; the steel frame structure 1 is fixedly installed with a transparent water tank 4, a water outlet is reserved at the bottom of the transparent water tank 4, and a water tank outlet valve 6 is installed at the position of the water outlet, and is reserved on the top of the transparent water tank 4 In the water inlet, a water tank inlet valve 5 is installed at the position of the water inlet; a planting area is provided on both outer sides of the transparent water tank 4, and a multi-layer planting tank 16 is installed inside the planting area; the water tank outlet valve 6 is located in the pipeline A three-way joint is installed on it to divide it into a water exchange channel and ...

Embodiment 2

[0047] Any one of the methods for making a device for a multi-purpose partition wall includes the following steps:

[0048] Step1: Material preparation: prepare light steel, transparent water tank 4, hook 2, shackle 3, transparent PC tube 13, main duct 14, shunt duct 15, activated carbon 8, barbed wire 10, valve and fixed rod 18;

[0049] Step2: Make steel frame structure 1: Use measuring tools to measure the size of the non-load-bearing wall, make steel frame structure 1 according to the measured data, and weld hooks 2 on the four top corners of steel frame structure 1;

[0050] Step3: Fixing the steel frame structure 1: Install the shackle 3 on the beam of the house frame, and connect the hook 2 on the steel frame structure 1 with the shackle 3 to fix the steel frame structure;

[0051] Step4: Design of the transparent water tank 4: Reserve a water outlet and water inlet at the bottom and top of the transparent water tank 4 respectively, and install the water tank outlet valve 6 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com