Loss amount detection device and method for grain harvesting machine

A detection device and detection method technology, applied in the agricultural field, can solve the problems of manpower consumption, inability to realize real-time monitoring, difficulty in achieving ideal precision, etc., and achieve the effect of saving manpower and material resources, improving operation performance and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Preferred embodiments of the present invention will be described in more detail below with reference to the accompanying drawings. Although preferred embodiments of the invention are shown in the drawings, it should be understood that the invention may be embodied in various forms and should not be limited to the embodiments set forth herein.

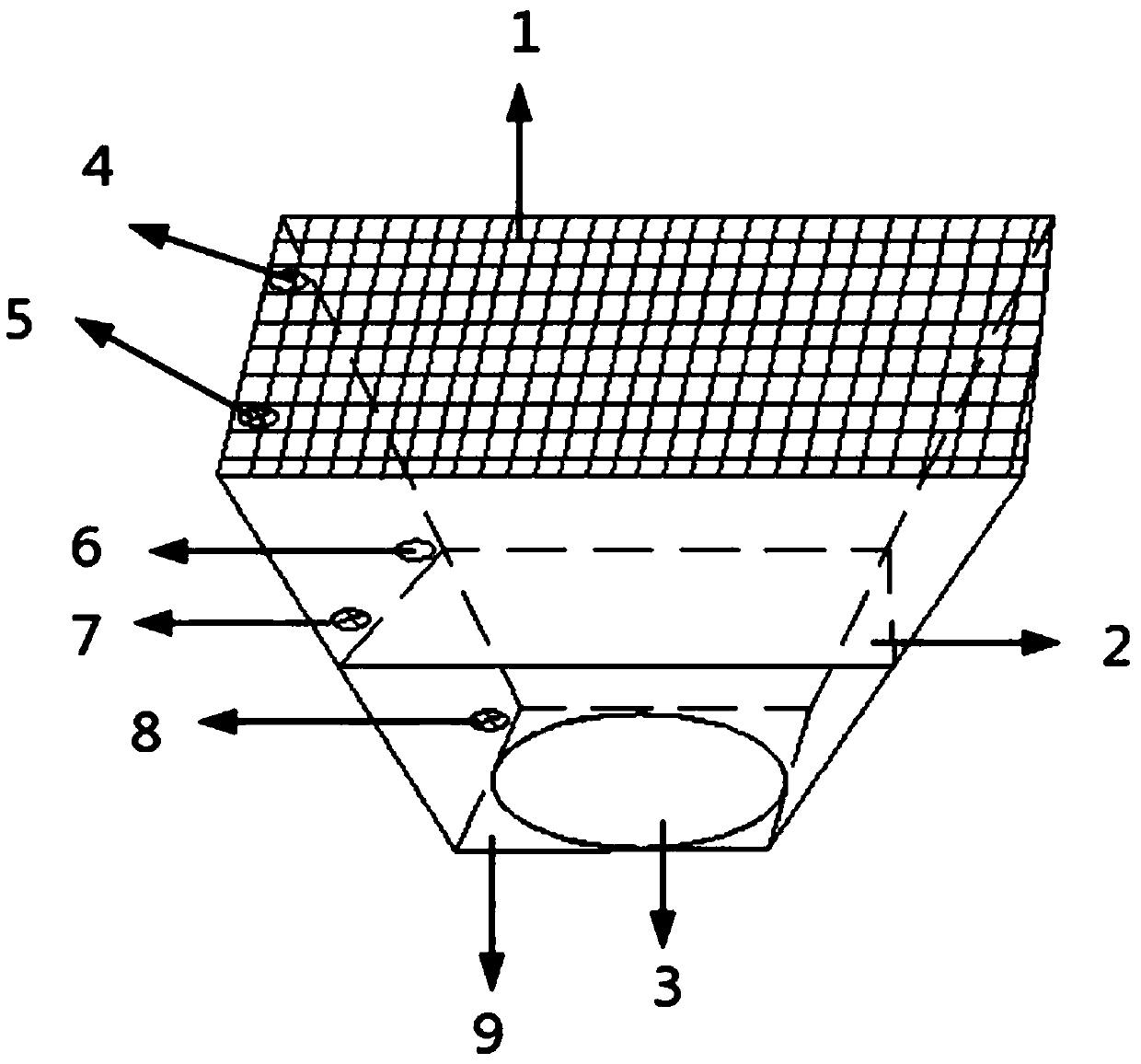

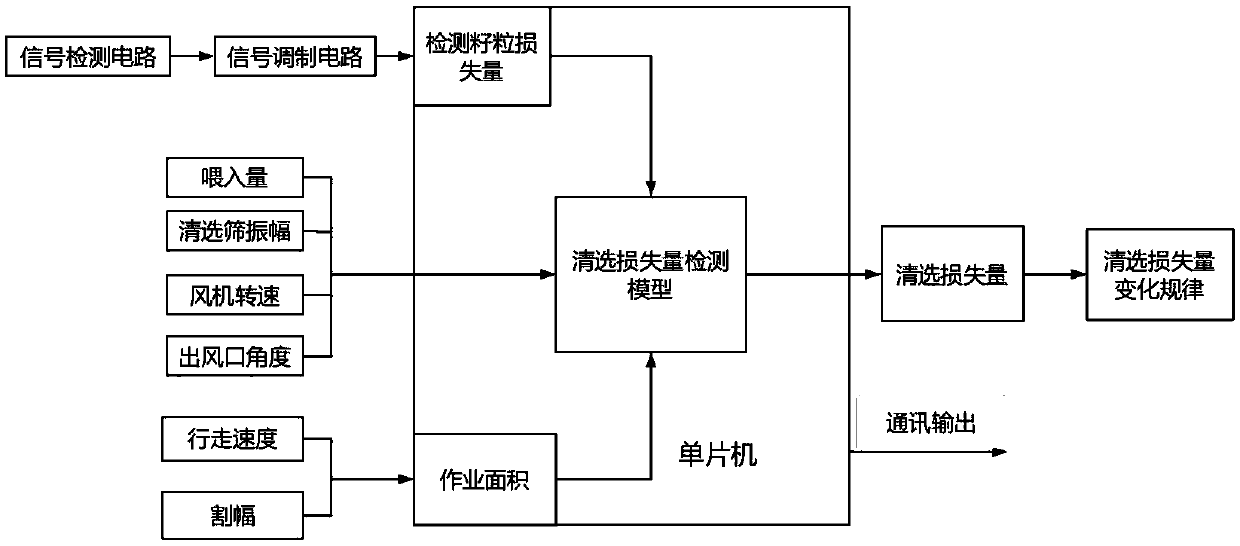

[0054]The cleaning loss detection system of the present invention comprises a loss detection device, a microcontroller, and a power supply module. The loss detection device is installed at the tail of the cleaning sieve. 4: Blow out the debris, motor 5: control the vibration of the vibrating screen 1); the second layer (collecting plate 2: collect the filtered grains, fan 6: blow out fine debris, motor 7: control the opening and closing of the collecting plate 2); Three layers (sensor element 3: detect the grain weight, supporting plate 9: fix the sensor, motor 8: control the opening and closing of the tray 9). The signal output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com