Method of monitoring and controlling industrial process, and process control system

A process control system and industrial process technology, applied in the direction of test/monitoring control system, general control system, control/regulation system, etc., to ensure uninterrupted operation, improve efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the following description, for purposes of explanation and not limitation, specific details are set forth, such as specific architectures, interfaces, techniques, etc., in order to provide a thorough understanding. In other instances, detailed descriptions of well-known devices, circuits, and methods are omitted so as not to obscure the description with unnecessary detail. Throughout the specification, the same reference numerals refer to the same or similar elements.

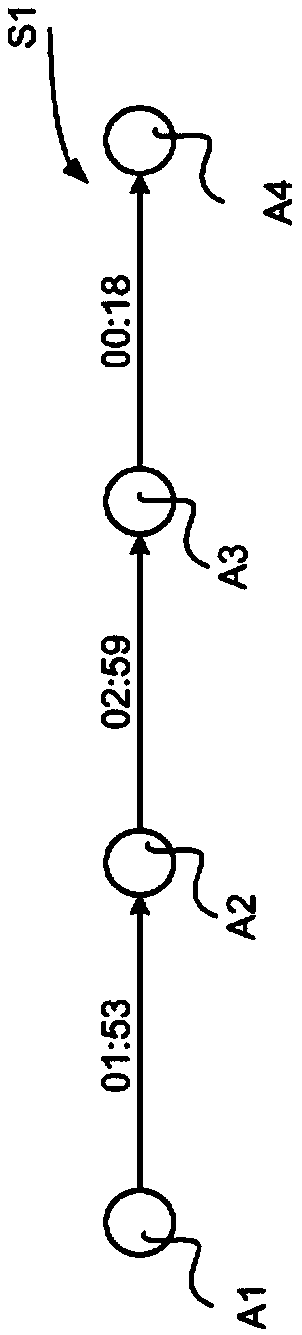

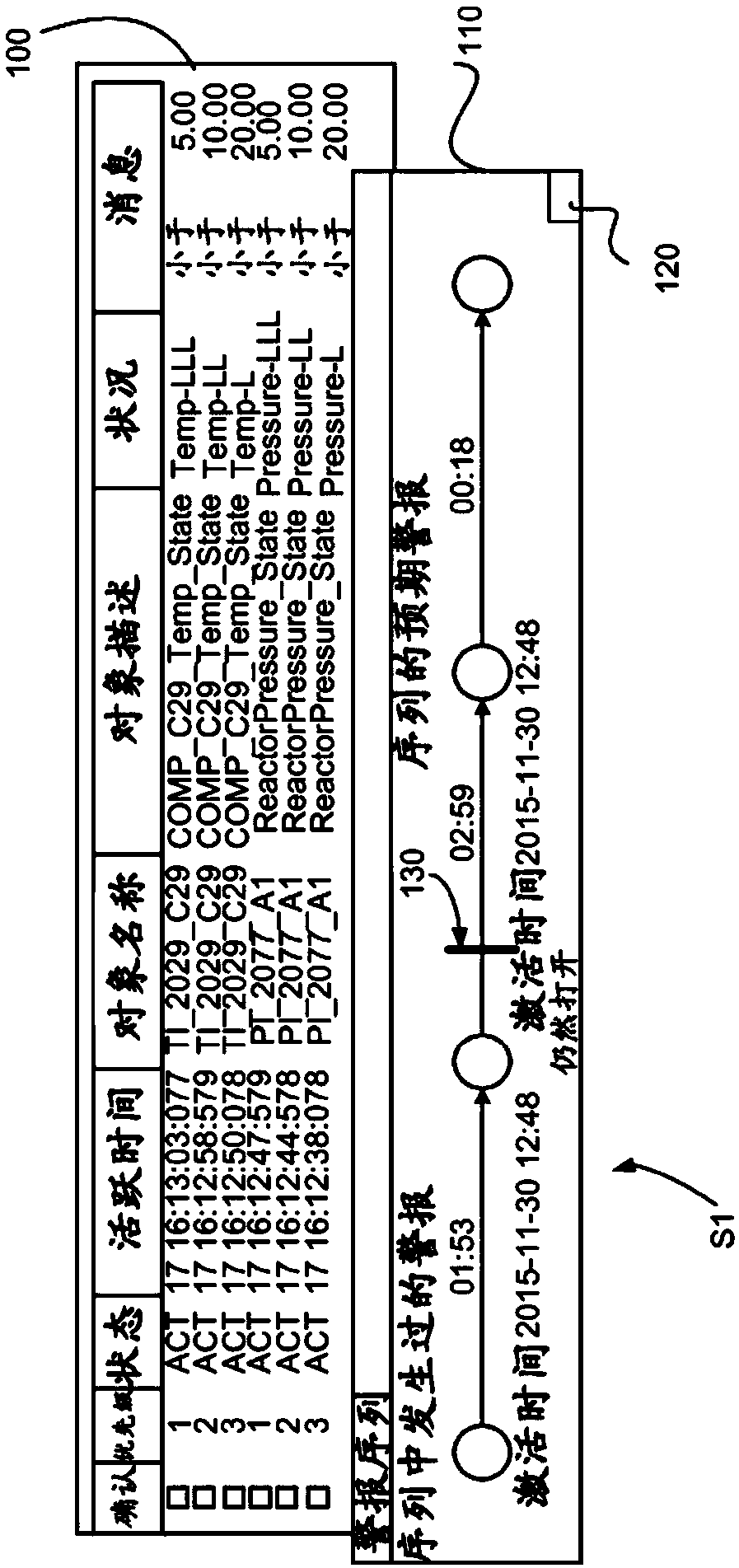

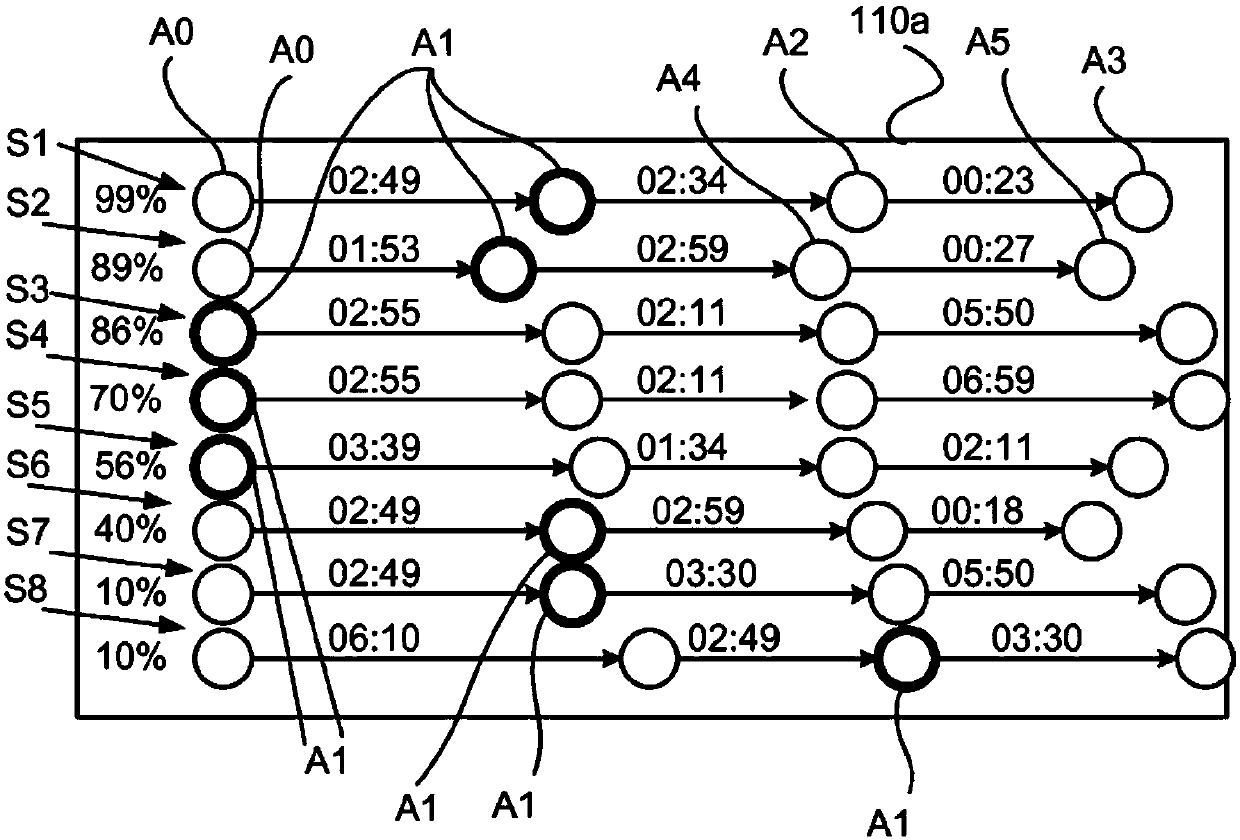

[0022] A typical current approach in industrial process control systems is that alarms are presented to operators in a common list in the order in which the alarms occurred. The current approach of notifying an operator about an alarm does not take into account that the alarms actually come as a sequence. For example, assume a process where a first process parameter (eg, temperature) is too high or too low. This triggers alert 1. Then, after a certain time, an asset involved in the process (eg a bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com