Millable silicone rubber composition, millable silicone rubber sponge, and method for producing said sponge

一种硅橡胶组合物、制造方法的技术,应用在建筑物构造、胶粘剂、门/窗的特殊设备等方向,能够解决硅橡胶海绵物性恶化等问题,达到尺寸精度优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

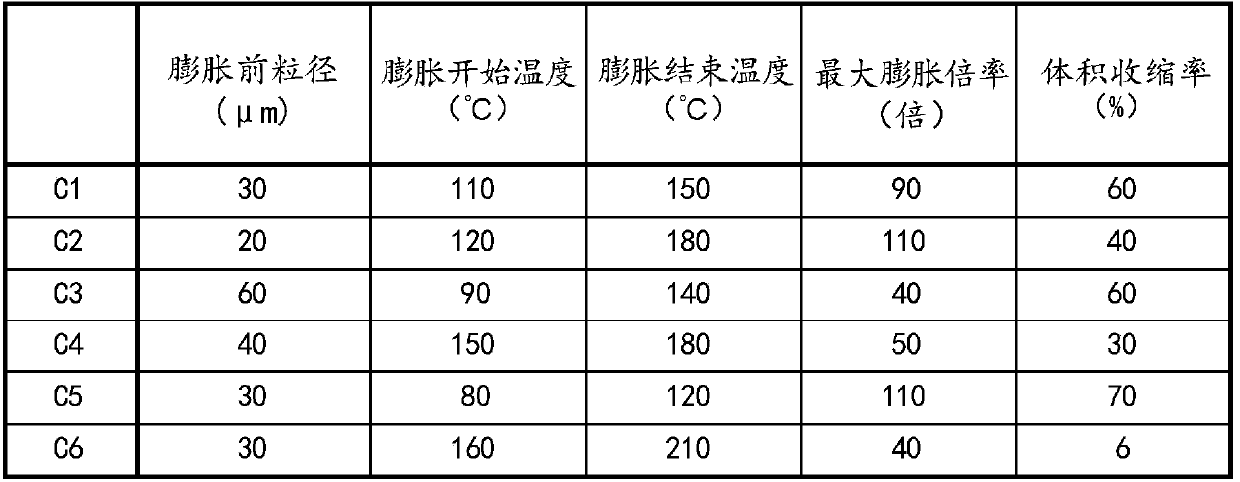

[0212] With respect to 145 parts by mass of base composition 1, add (C1) 3.0 parts by mass of heat-expandable microcapsules, 2,5-dimethyl-2,5-di-(t-butyl peroxide) as a curing agent (D1) ) 1.5 parts by mass of hexane and 7.0 parts by mass of azodicarbonamide (theoretical gas generation 1400cc) of the continuous foaming agent (E1), and then mixed with a two-roll mill to produce a 9mm thick uncrosslinked rubber combination object piece.

[0213] Next, the uncrosslinked rubber composition sheet with a thickness of 9 mm was subjected to hot air crosslinking under normal pressure in a hot air drier at 230° C. for 30 minutes to obtain a silicone rubber sponge.

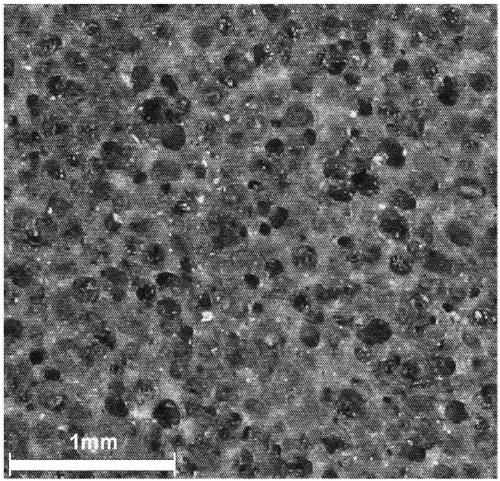

[0214] Thereafter, the obtained silicone rubber sponge was post-cured at 230° C. for 2 hours. The state of the pores of the obtained sponge was confirmed / evaluated as above, and the hardness of the sponge, the expansion ratio, the average pore diameter, the aspect ratio of the pores (sphericality) and continuous foam were i...

Embodiment 2

[0217] With respect to 145 mass parts base composition 1, add 2.3 mass parts (C2) heat-expandable microcapsules, 1.2 mass parts as the dicumyl peroxide of curing agent (D2) and 3.5 mass parts as continuous foaming agent (E2) Azodicarbonamide (theoretical gas generation amount: 690 cc) containing urea was mixed with a two-roll mill, and a sponge was produced in the same manner as in Example 1. Thereafter, in the same manner as in Example 1, the evaluation results of the sponge are shown in Table 2.

Embodiment 3

[0219] With respect to 145 parts by mass of base composition 1, add 3.0 parts by mass (C3) of thermally expandable microcapsules, 1.8 parts by mass of tert-butyl peroxide as a curing agent (D3) and 4.5 parts by mass as a continuous foaming agent N,N'-dinitrosopentamethylenetetramine (theoretical gas generation amount: 1100 cc) of (E3) was further mixed with a two-roll mill, and a sponge was produced in the same manner as in Example 1. Thereafter, in the same manner as in Example 1, the evaluation results of the sponge are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com