Electric appliance, power device, and method for forming same

A technology for power devices and electrical appliances, which is applied to the formation method of power devices and the field of electrical appliances, can solve the problems of low reliability, high cost, and increased body area of power devices, and achieve consistency, weight reduction, and area saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

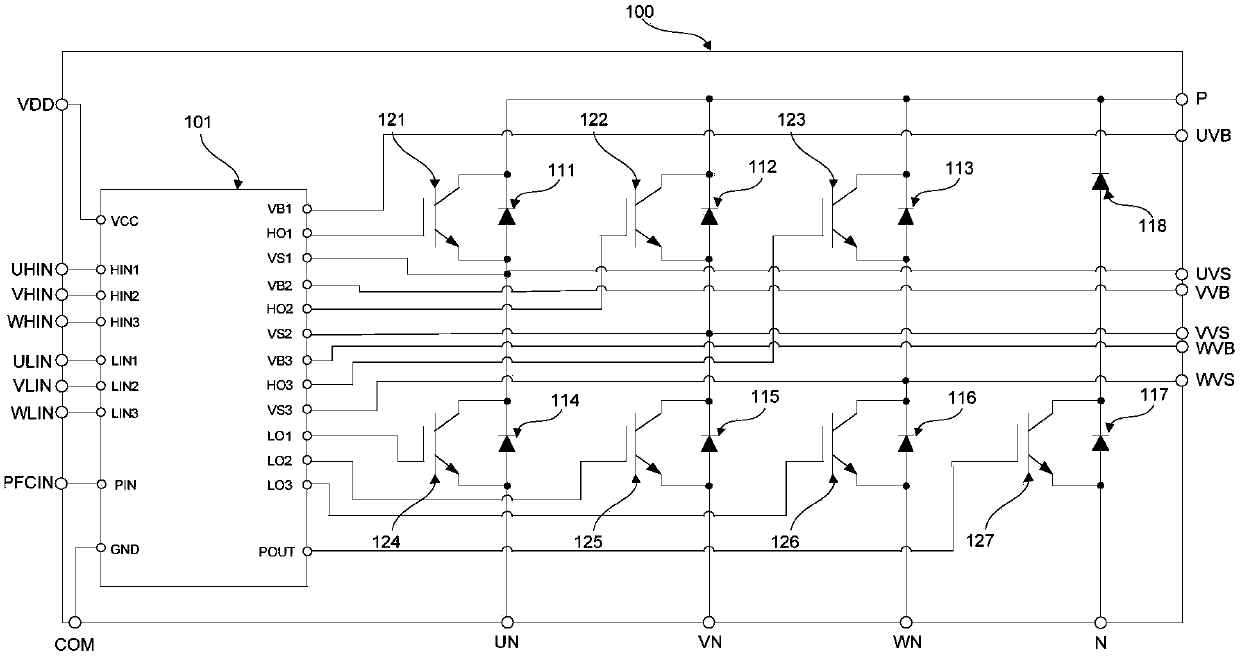

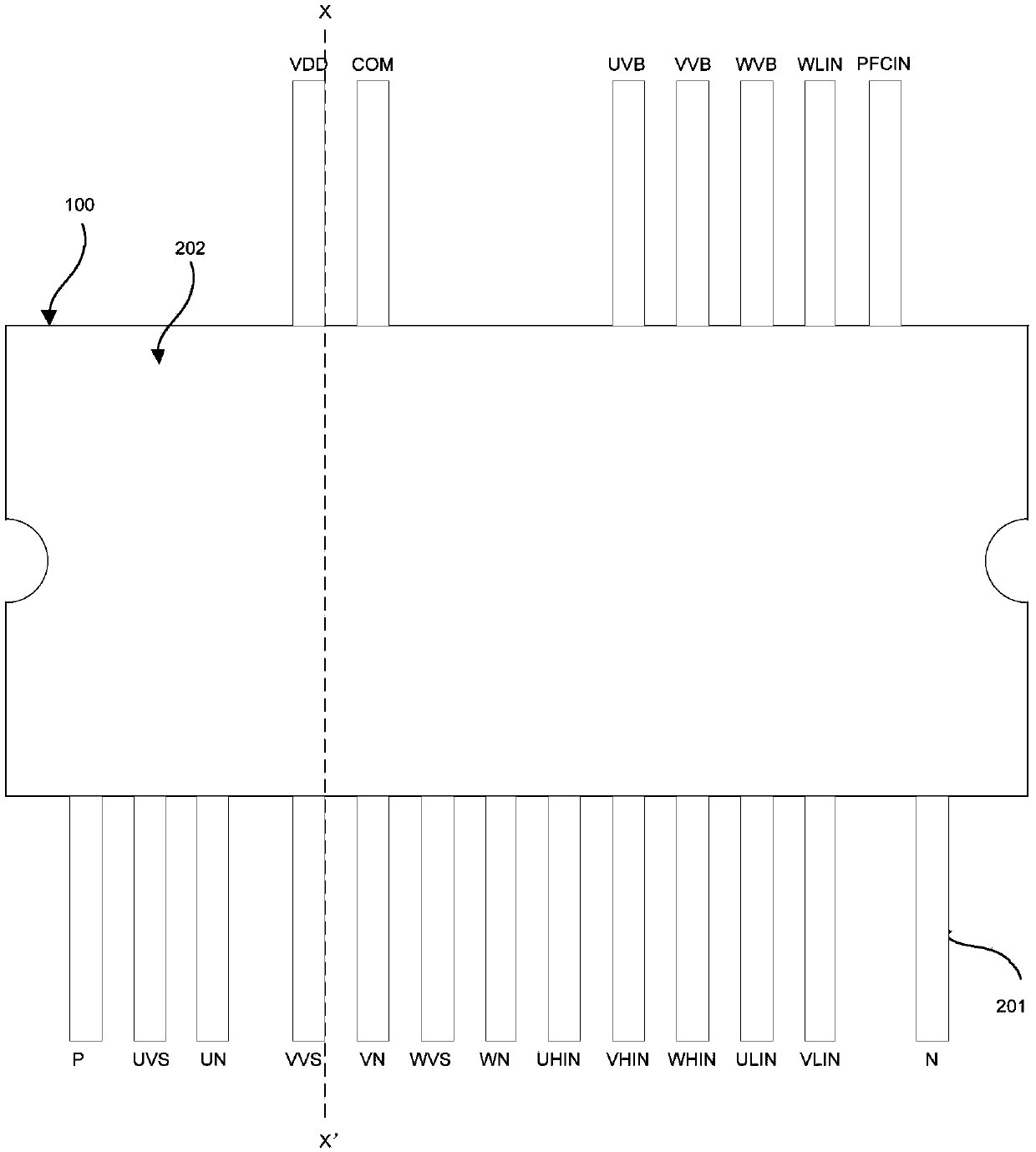

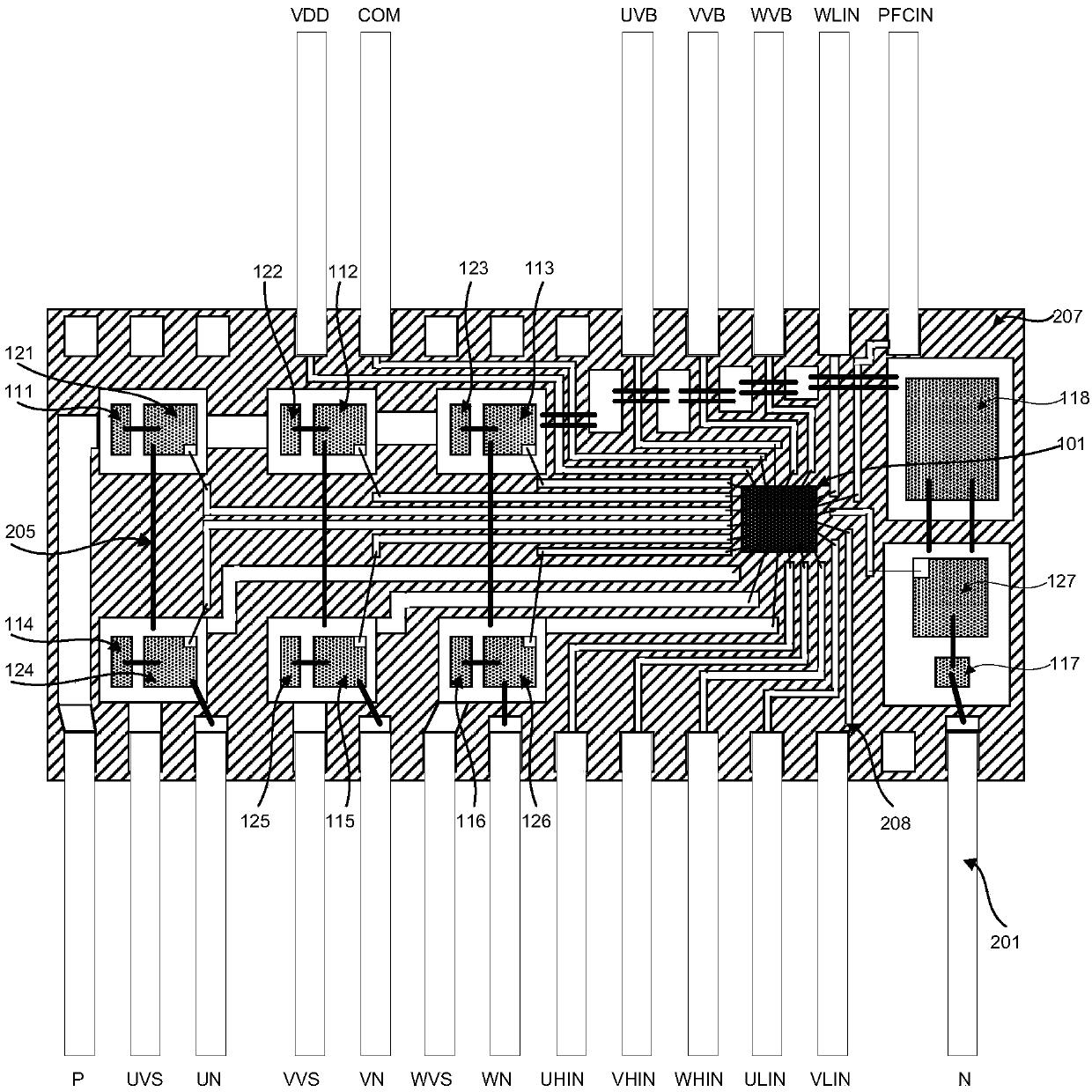

[0033] Before introducing the embodiment of this application, first combine Figure 1a~1e Power devices such as the intelligent power module 100 in related technologies are introduced.

[0034] refer to Figure 1a , the positive terminal VCC of the power supply of the HVIC tube 101 in the intelligent power module 100 is used as the positive terminal VDD of the power supply in the low-voltage area of the intelligent power module 100, and VDD is generally 15V; the HIN1 terminal of the HVIC tube 101 is used as the U-phase upper bridge of the intelligent power module 100 The arm input terminal UHIN; the HIN2 terminal of the HVIC tube 101 serves as the V-phase upper bridge arm input terminal VHIN of the intelligent power module 100; the HIN3 terminal of the HVIC tube 101 serves as the W-phase upper bridge arm input terminal WHIN of the intelligent power module 100; the HVIC tube 101 The LIN1 terminal of the HVIC tube 101 is used as the U-phase lower bridge arm input terminal ULIN...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com