Display panel

A display panel and display area technology, applied in the direction of instruments, electrical digital data processing, electrical components, etc., can solve the problems of metal residue, metal residue in difficult post-metal manufacturing process, and defective panels, so as to improve the yield rate and avoid the risk of short circuit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

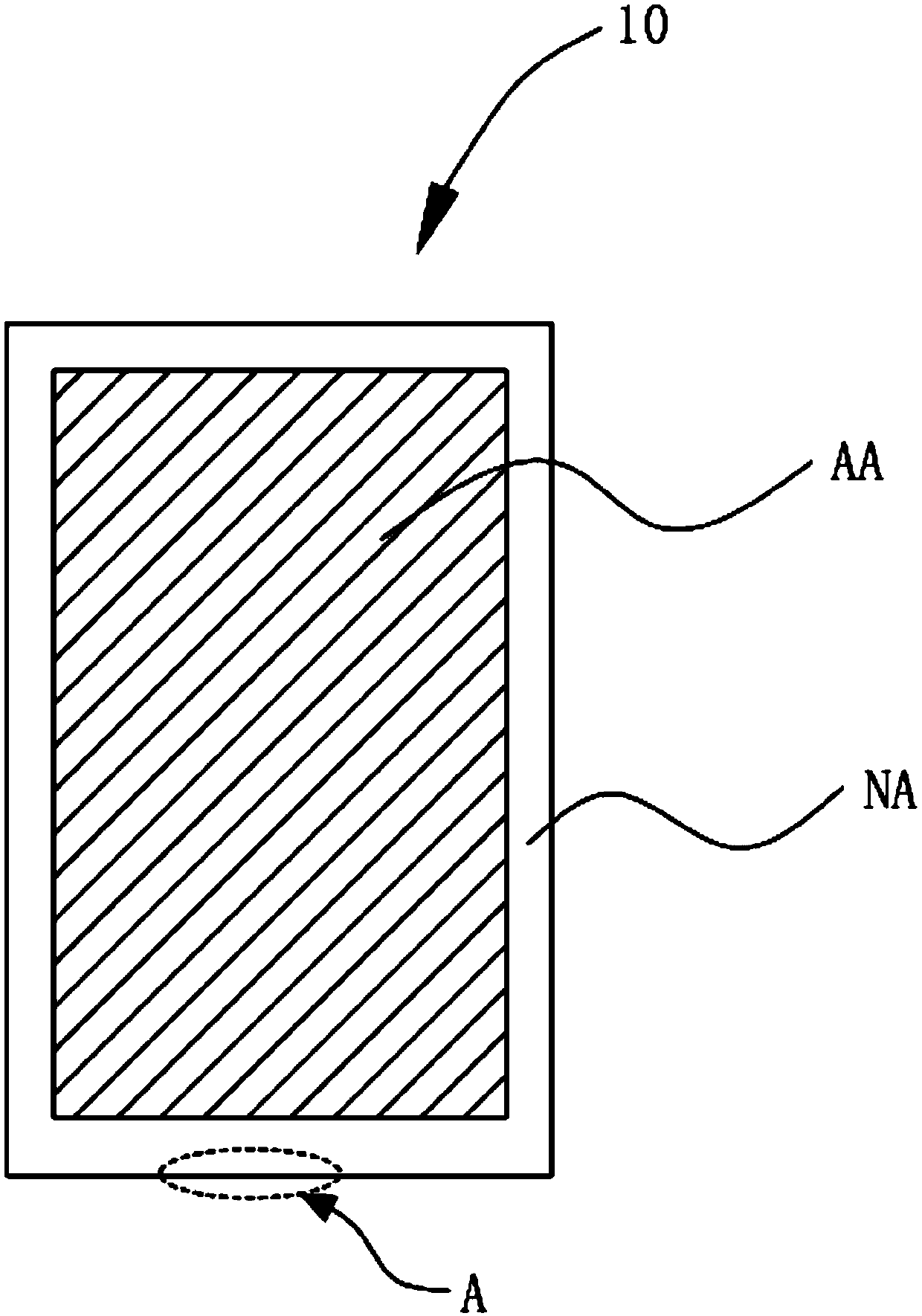

[0031] like figure 2 As shown, this embodiment provides a display panel 10, which defines a display area AA and a non-display area NA disposed outside the display area AA, and the non-display area NA in this embodiment surrounds the display area AA is set, the display area AA is used to display images, and the non-display area NA is used to accommodate signal wiring and other components that block light.

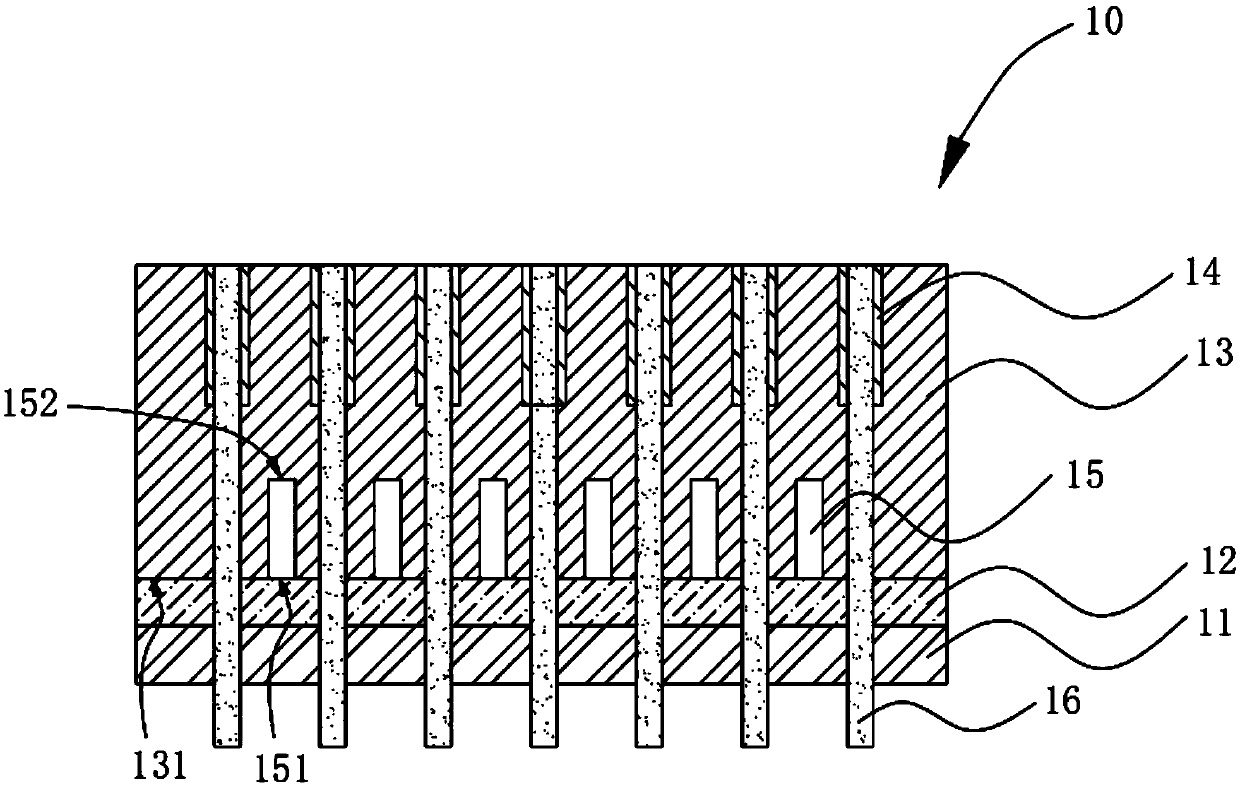

[0032] like image 3 as shown, image 3 for figure 2 Schematic diagram of the enlarged structure at A in, image 3 In a top view, the display panel 10 includes a base substrate 11 , an inorganic layer 12 , an organic layer 13 , a plurality of binding terminals 14 , and a plurality of signal terminals 16 .

[0033] Wherein, the inorganic layer 12 is disposed on the base substrate 11 , the organic layer is disposed on the inorganic layer 12 , and a plurality of binding terminals 14 are disposed on the organic layer 13 in parallel.

[0034] The organic layer 13 is provid...

Embodiment 2

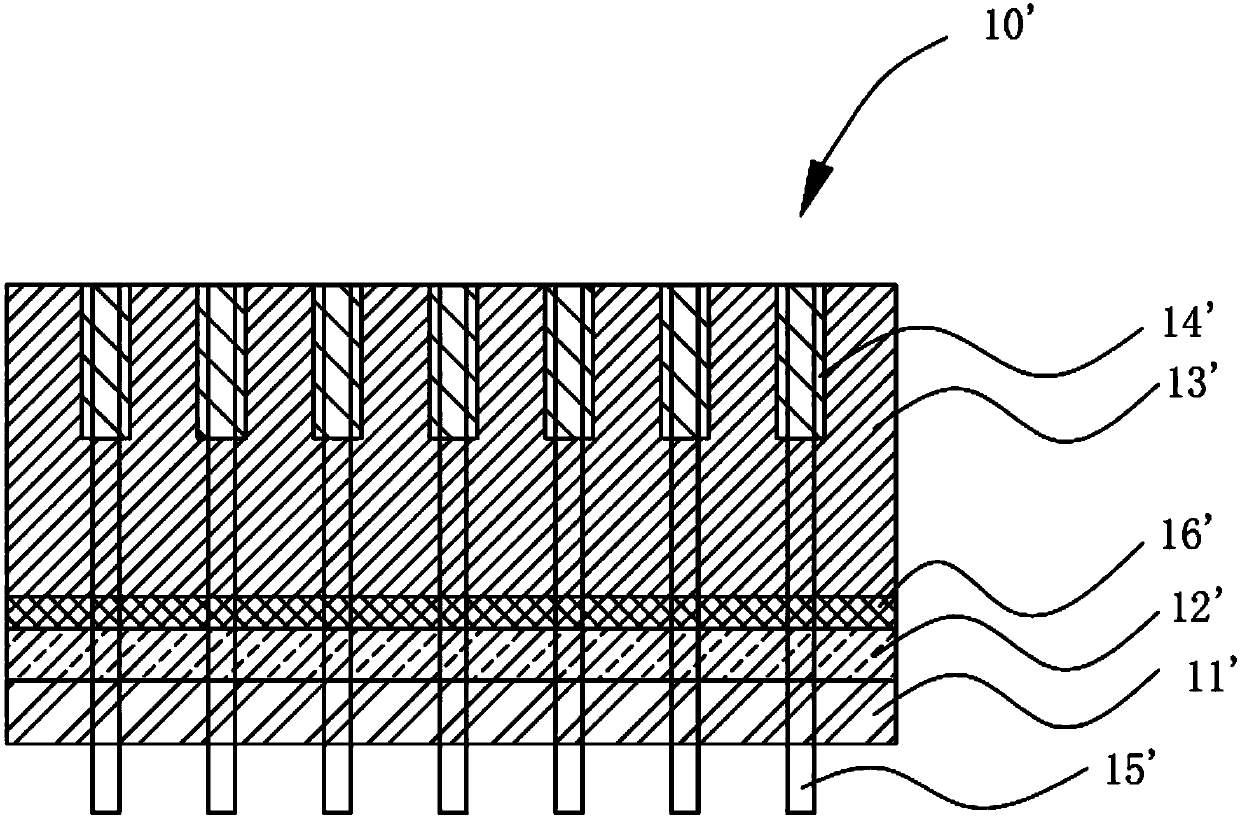

[0049] like Figure 5 As shown, the display panel 20 includes a base substrate 21, an inorganic layer 22, an organic layer 23, a plurality of binding terminals 24, and a plurality of signal terminals (not shown in the figure).

[0050] A plurality of grooves 25 are opened on the organic layer 23 , and the grooves have opposite first sides 251 and second sides 252 .

[0051] Different from the first embodiment, the length of the groove 25 is different, and the second side 252 of the groove 25 is flush with the side of the binding terminal 24 close to the display area.

[0052] Other structures are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0054] Please refer to Image 6 and Figure 7 The display panel 30 includes a base substrate 31, an inorganic layer 32, an organic layer 33, a plurality of binding terminals 34, and a plurality of signal terminals 36 (not shown in the figure), and the organic layer 33 has multiple Groove 35

[0055] The grooves 35 in this embodiment adopt a thinner and more design, so that the residual metal 37 in the post-metal process forms more discontinuous small pieces of metal, further reducing the risk of short circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com