Anti-vibration spiral protection sleeve

A Protective Sleeve, Spiral Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

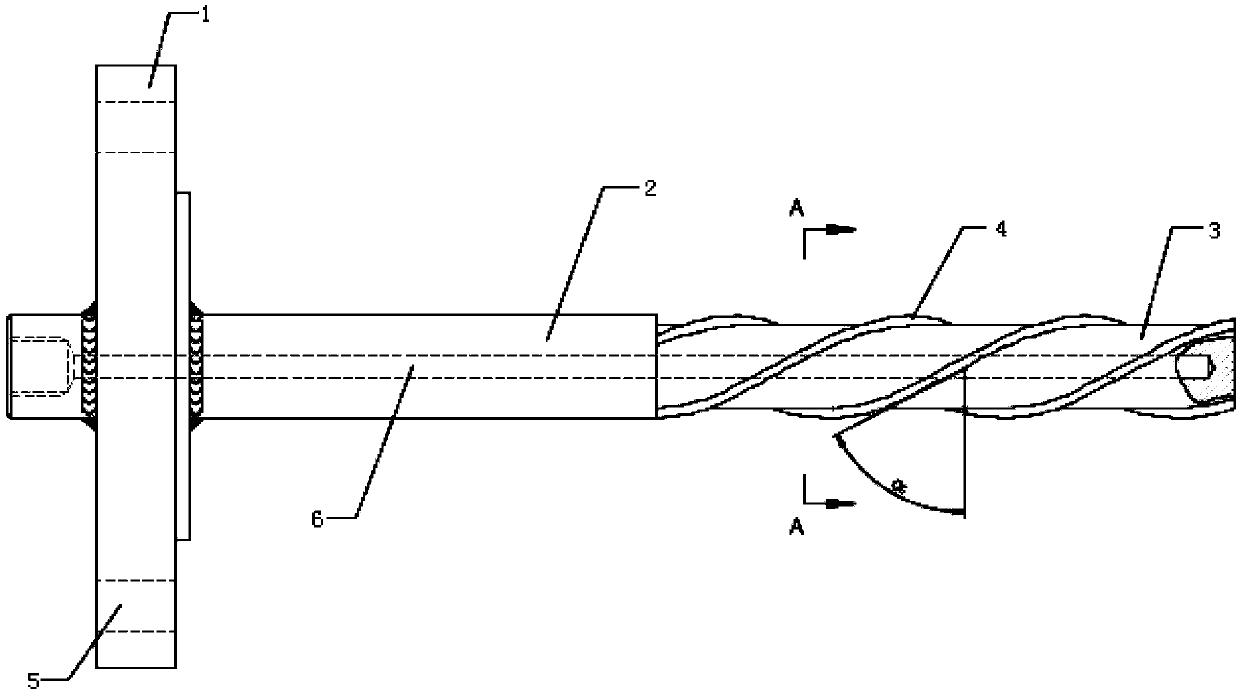

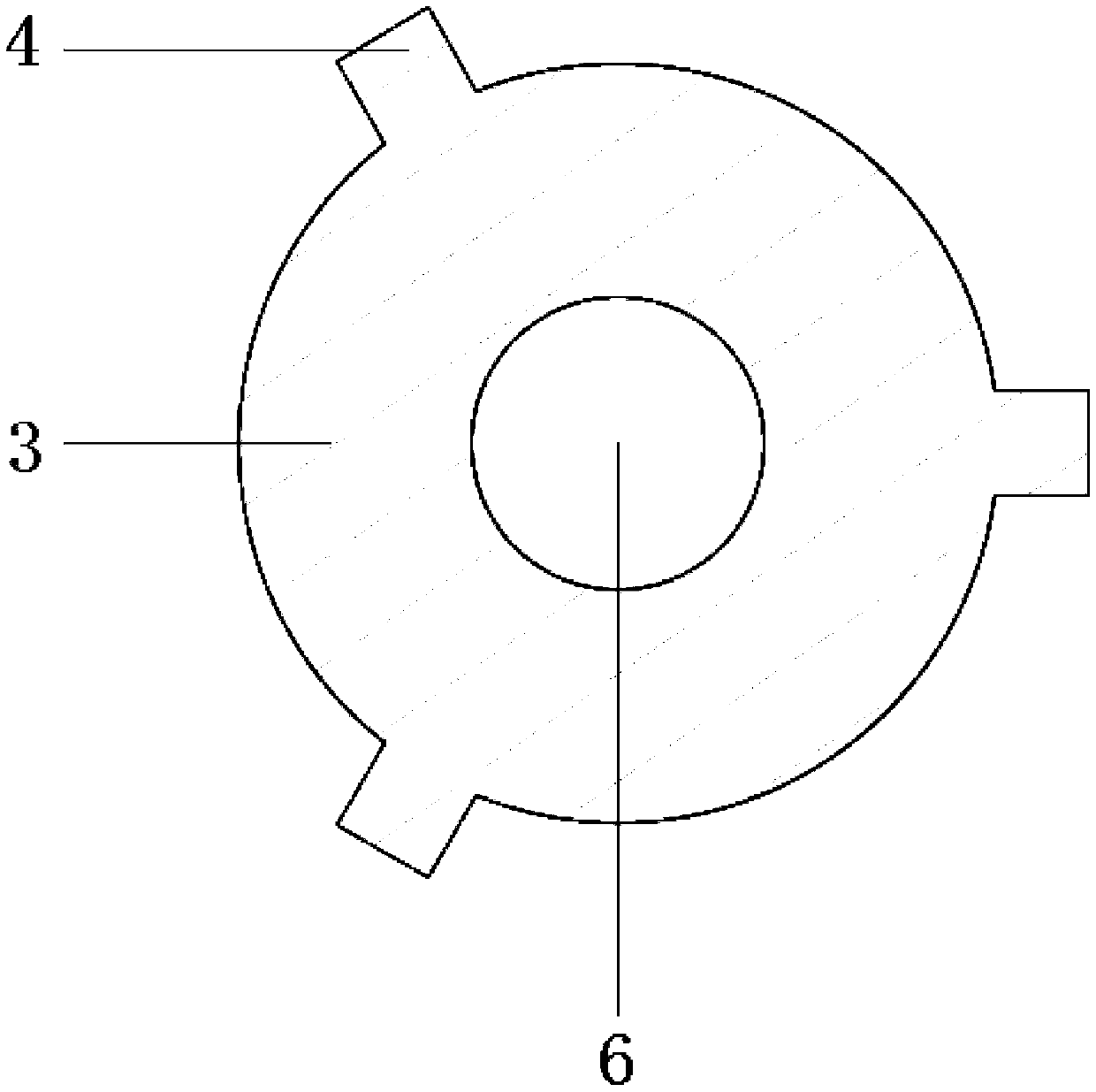

[0030] When the integral structure between the spiral flange 4 and the spiral flange sleeve 3, such as figure 2 , the spiral flange 4 arranged around the protective sleeve can cut off the fluid, thus avoiding the formation of obvious Karman vortex street. By reducing the amplitude of the dispersed vortex, the vibration of the protective casing is avoided, and the vibration problem of the protective casing in the high flow rate environment is solved. At the same time, the spiral flange 4 is provided on the spiral protective casing, which can increase the protective casing The area in contact with the medium increases the heat conduction efficiency, thereby making the temperature measurement of the temperature measuring element in the protective sleeve more accurate and the thermal response time faster, which solves the temperature measurement that may be caused by shortening the length of the protective sleeve or increasing the outer diameter of the protective sleeve. The prob...

Embodiment 2

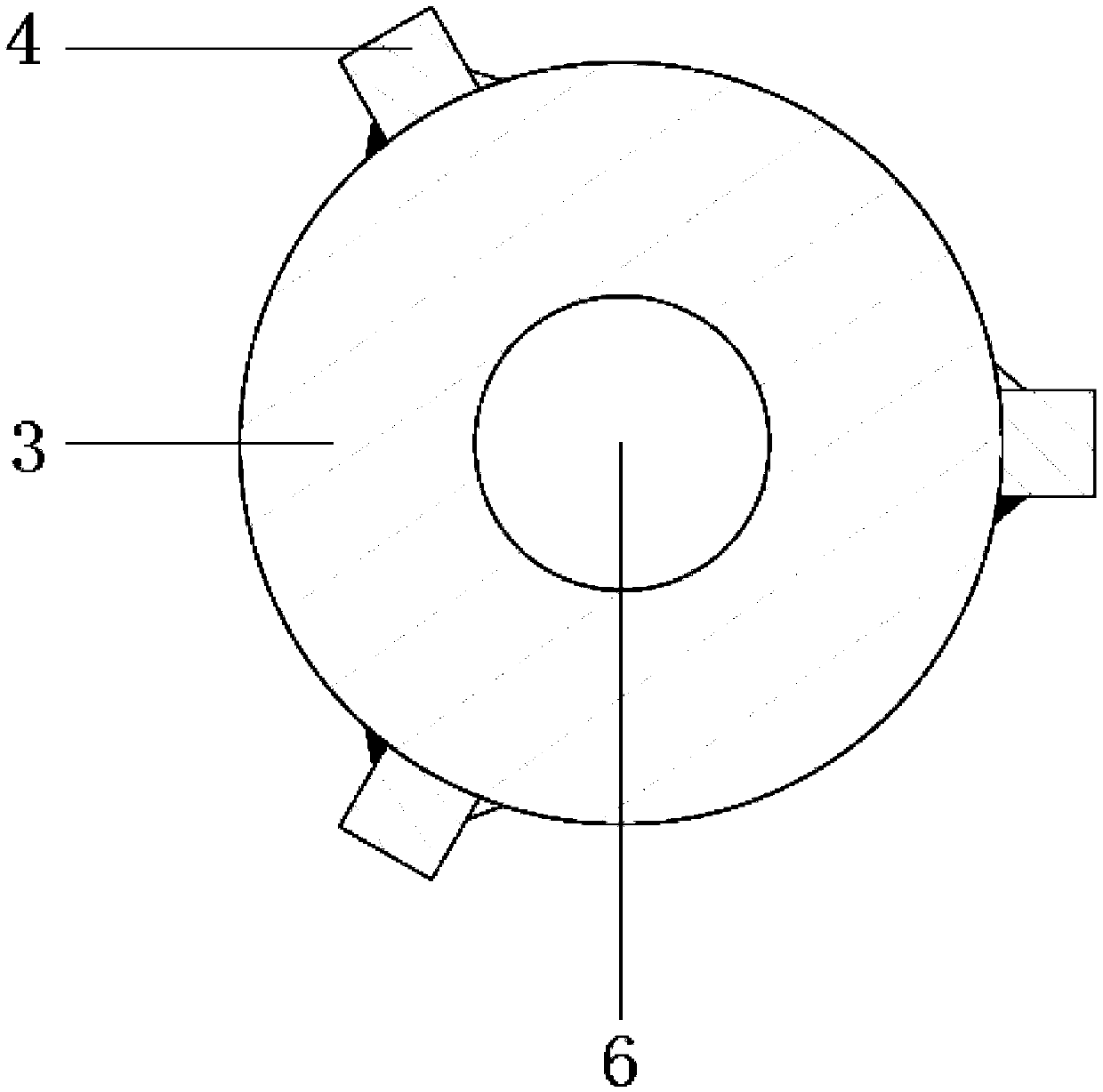

[0032] When there is a welded structure between the spiral flange 4 and the spiral flange sleeve 3, as image 3 , the spiral flange 4 arranged around the protective sleeve can cut off the fluid, thus avoiding the formation of obvious Karman vortex street. By reducing the amplitude of the dispersed vortex, the vibration of the protective casing is avoided, and the vibration problem of the protective casing in the high flow rate environment is solved. At the same time, the spiral flange 4 is provided on the spiral protective casing, which can increase the protective casing The area in contact with the medium increases the heat conduction efficiency, thereby making the temperature measurement of the temperature measuring element in the protective sleeve more accurate and the thermal response time faster, which solves the temperature measurement that may be caused by shortening the length of the protective sleeve or increasing the outer diameter of the protective sleeve. The probl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com