Wind power gear box tool base capable of adjusting connecting size

A wind power gearbox and adjustable technology, applied in wind energy power generation, wind turbines, machines/engines, etc., can solve the problems of prolonged maintenance period, high tooling procurement cost, and small applicability, so as to reduce storage space and costs, shorten the Procurement cycle, the effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to illustrate the technical solution of the present invention more clearly, the accompanying drawings that need to be used in the description will be briefly introduced below. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention. As far as people are concerned, other embodiments can also be obtained according to these drawings on the premise of not paying creative work.

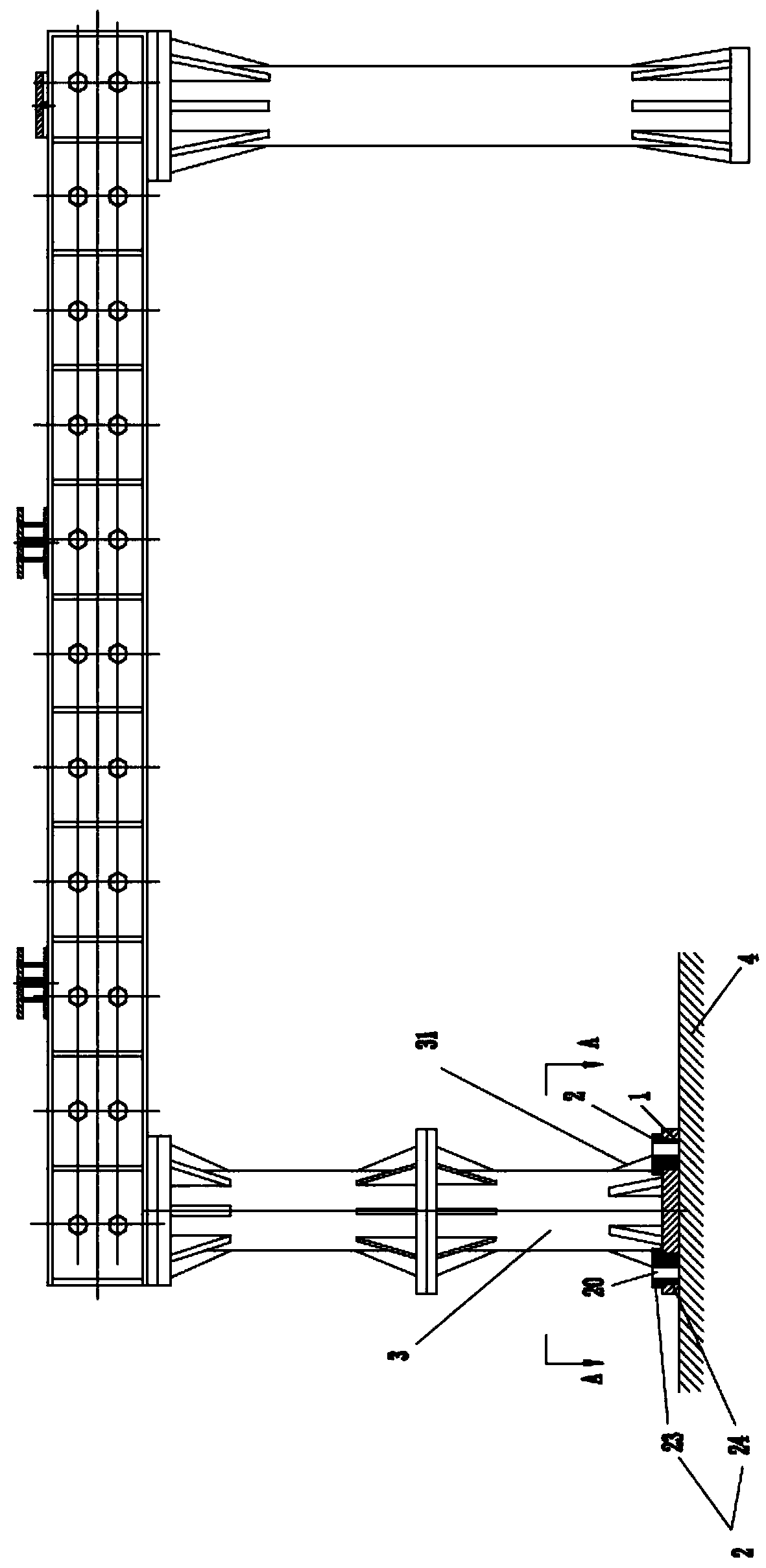

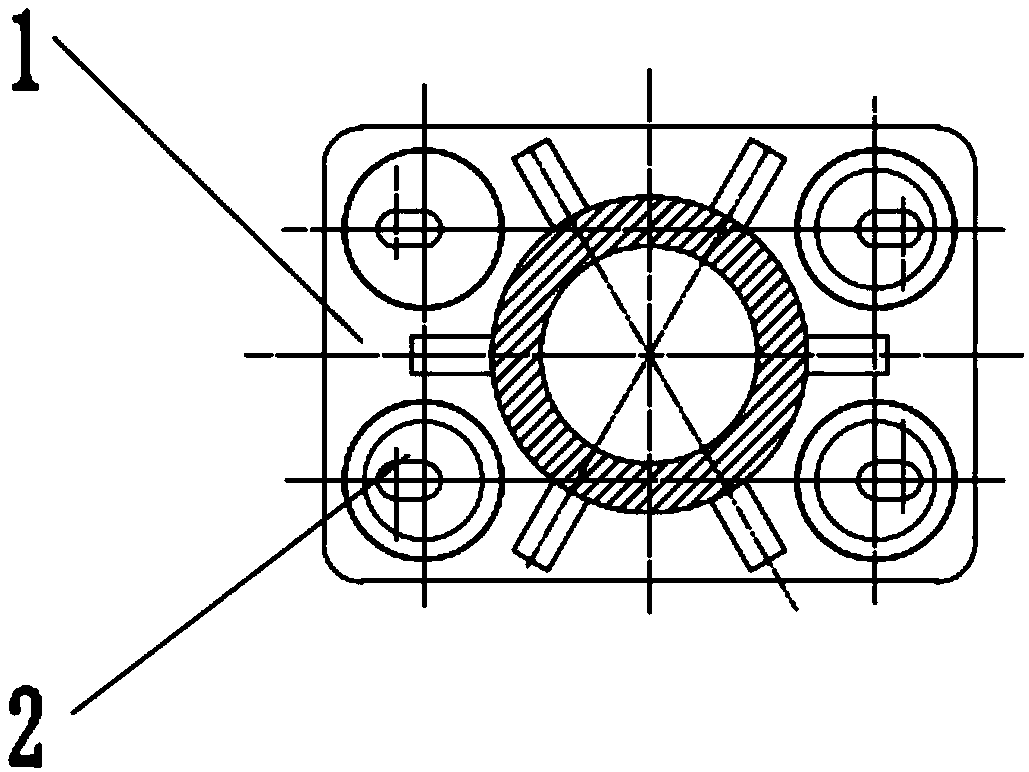

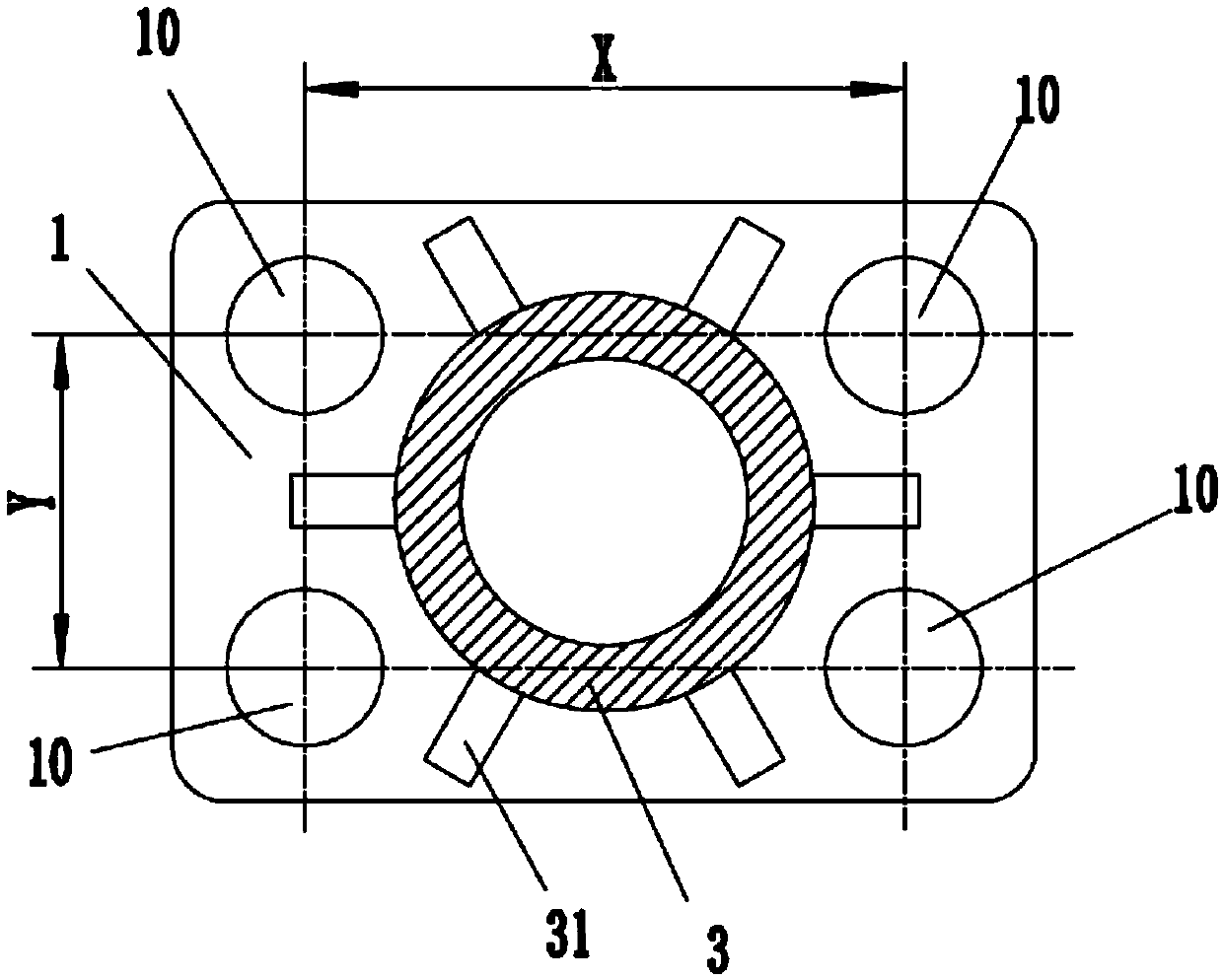

[0022] Such as image 3 As shown, the tooling base component 1 is welded and fixed at the lower end of the tooling support column 3, and has a circle of 6 circumferentially evenly distributed ribs 31 respectively welded on the tooling support column 3 and the upper surface of the tooling base component 1 In order to strengthen the support column 3 of the tooling, the tooling base component 1 is provided with 4 vertical cylindrical base component through holes 10, and the axes of the 4 vertical base component through holes 10 are d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com