Scrabbling plate device

A technology of scraping plates and teeth, applied in the field of railway maintenance equipment, can solve the problems of short service life of components, many weak links and high processing costs, and achieve the effects of prolonging the service life, reducing costs and low processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

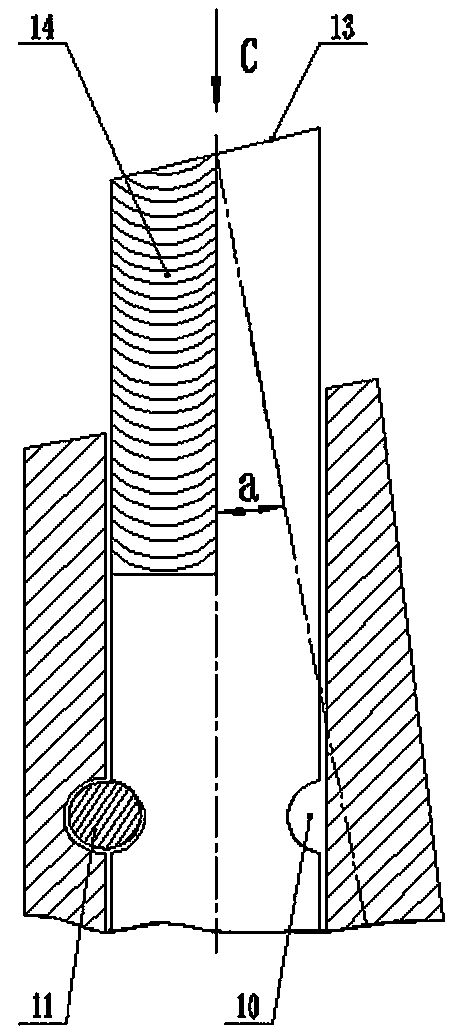

[0024] see figure 1 , figure 2 , image 3 , Figure 4 , a grilling device, comprising a grilling board 5, a link hole 2 is provided at the lower position of the grilling board 5, and each grilling board 5 can be linked by an intermediate linking board 3 and a link pin 4, and the palm surface of the grilling board 5 It is in a concave structure 1, and the back of the palm surface is provided with a grilling tooth installation hole 9, and the grilling tooth installation hole 9 is provided with grilling teeth.

[0025] The heads of the grilling teeth protrude from the grilling plate 5, and the grilling teeth protrude from the front end of the palm part for a certain distance L, so as to pre-loosen the hardened and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com