A method for improving electrical conductivity of a carbon nanotube composite material

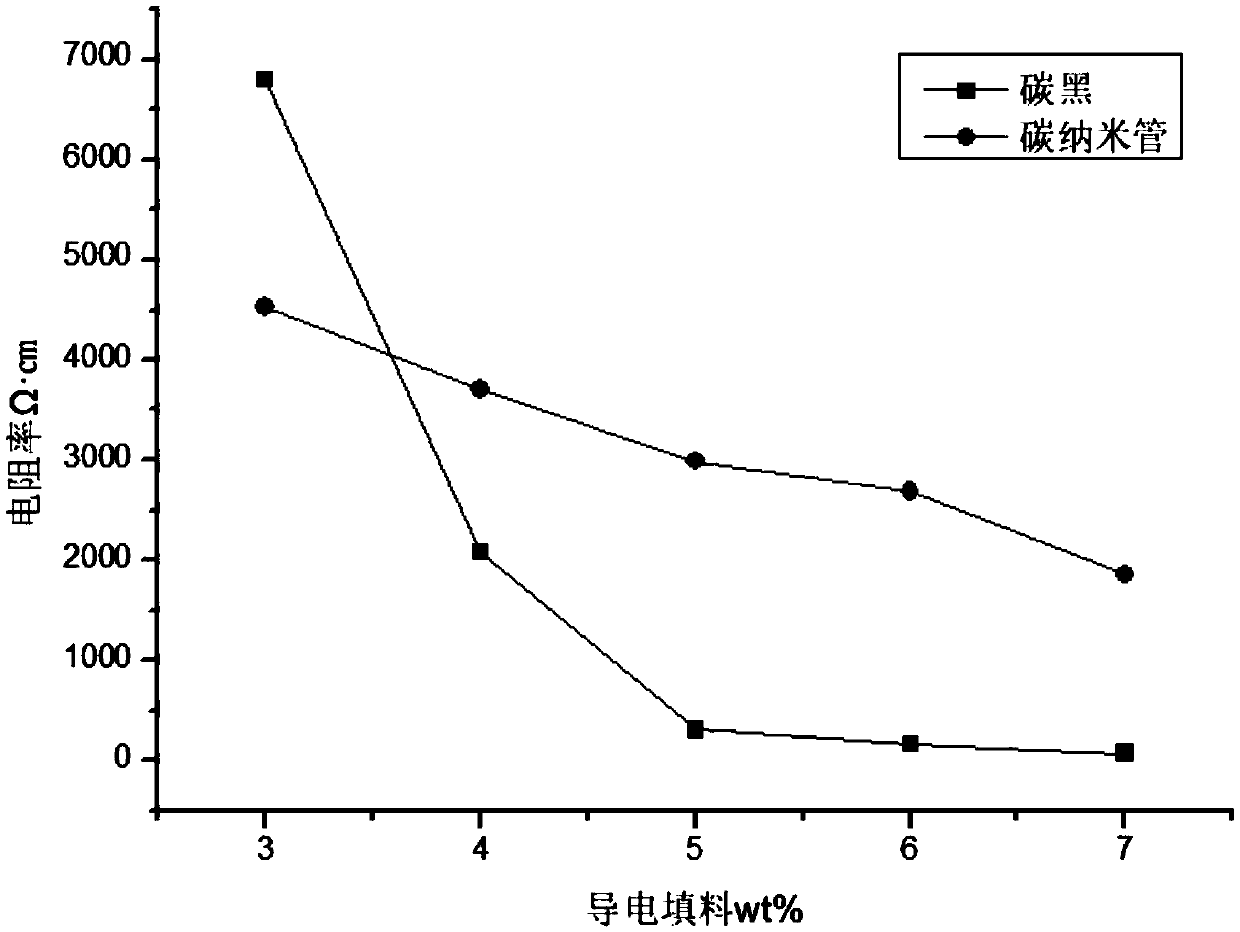

A carbon nanotube and composite material technology, applied in the field of conductive materials, can solve the problem of slow decline in the resistivity of carbon nanotube content, and achieve the effects of saving consumption, improving electrical conductivity, and improving the rate of decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

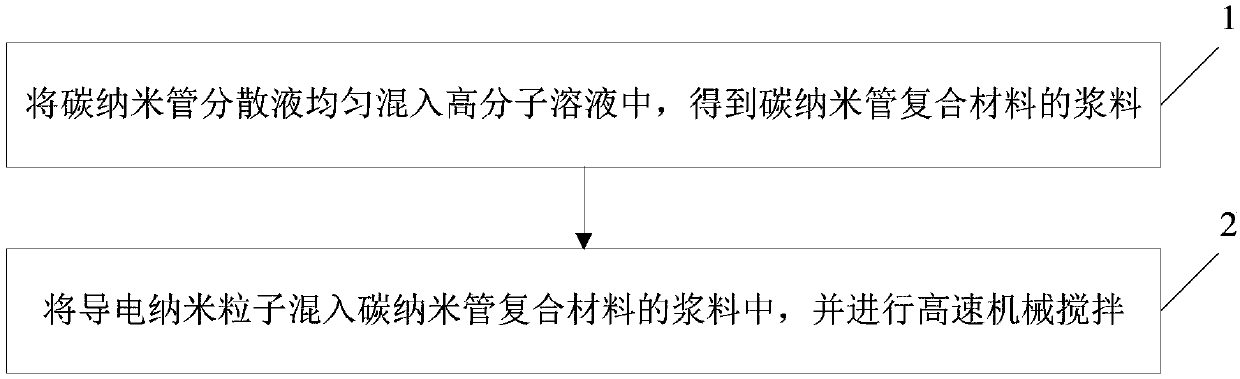

Method used

Image

Examples

Embodiment 1

[0032] Step (1): uniformly mix 5.83g of carbon nanotube dispersion with 10wt% solute into 15g of aqueous polyurethane solution with 35wt% solute to obtain carbon nanotube composite material slurry with 10wt% carbon nanotube dry weight.

[0033] Step (2): 0.18g nano-carbon black is mixed in the carbon nanotube composite material slurry, carries out mechanical stirring 3h with the rotating speed of 300r / min, makes the carbon nanotube composite material slurry that improves electrical conductivity, and nano-carbon black is dry Weight is 3 wt%.

Embodiment 2

[0035] The difference from Example 1 is that 0.243g nano-carbon black is mixed into the carbon nanotube composite material slurry, and the dry weight of nano-carbon black is 4wt%.

Embodiment 3

[0037] The difference from Examples 1 and 2 is that 0.307 g of nano-carbon black is mixed into the carbon nanotube composite material slurry, and the dry weight of nano-carbon black is 5 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com