Oil filling control method used for automobile high-pressure oil tank

A high-pressure fuel tank, refueling control technology, applied in vehicle components, layout and packaging combined with internal combustion engine fuel supply, can solve problems such as human injury, environmental damage, oil vapor spillage, etc., to avoid injury, environmental friendliness, and application range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

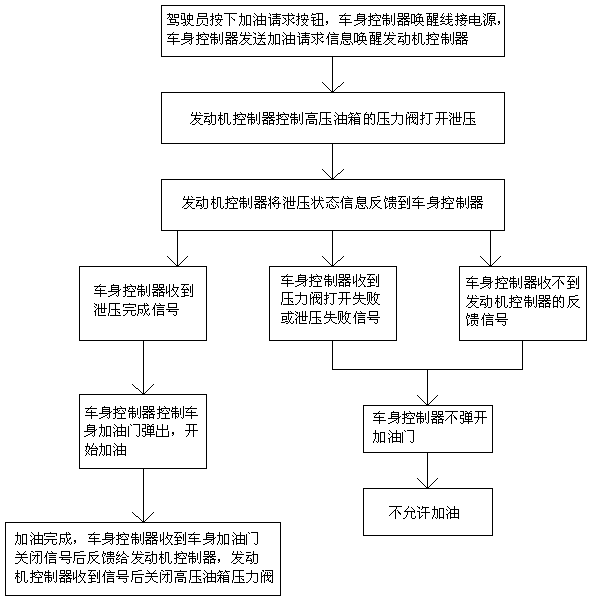

Method used

Image

Examples

Embodiment 1

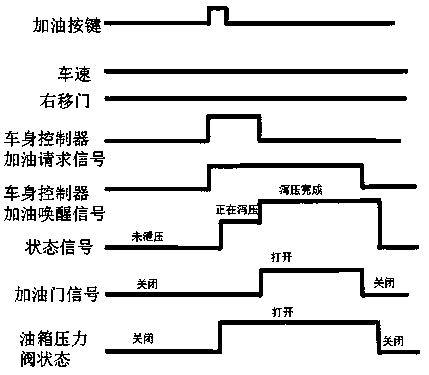

[0039] Please see attached figure 2 , the vehicle is stationary, press the refueling request button, the right door is not opened, the body controller sends a refueling request message to wake up the engine controller, the engine controller controls the pressure valve of the high-pressure fuel tank to open, and starts to release pressure; after the pressure relief is completed, the pressure relief state The information is fed back to the body controller, and the body controller controls the fuel door of the body to pop up, and refueling can be started. At this time, the refueling request of the body controller outputs a low level; level, the pressure valve of the high-pressure fuel tank is closed after the pressure relief is completed.

Embodiment 2

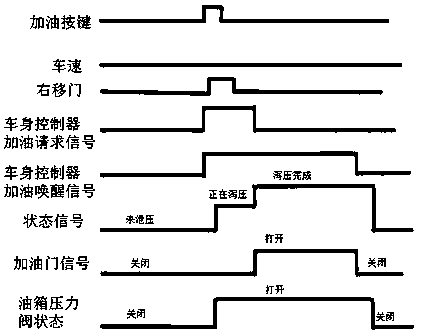

[0041] Please see attached image 3 , the vehicle is stationary, press the refueling request button, the right door is opened after the refueling request and before the refueling door is opened, refueling is not affected. The body controller sends the refueling request information to wake up the engine controller, and the engine controller controls the pressure valve of the high-pressure fuel tank to open to start the pressure relief; after the pressure relief is completed, the pressure relief status information is fed back to the body controller, and the body controller controls the fuel valve of the body to pop up , you can start refueling. At this time, the body controller refueling request outputs a low level; after refueling is completed, the refueling valve is closed, and the body controller refueling wake-up signal outputs a low level. After the pressure relief is completed, the high-pressure fuel tank pressure valve is closed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com