Charging port and high voltage electrical wiring harness arrangement structure

A high-voltage wire and layout technology, which is applied in charging stations, electric vehicle charging technology, electric vehicles, etc., can solve the problems of excessively long charging high-voltage wire bundles, reducing the convenience of charging operations, and worsening the sealing of the passenger compartment. The effect of charging convenience, simplified structure, and shortened length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

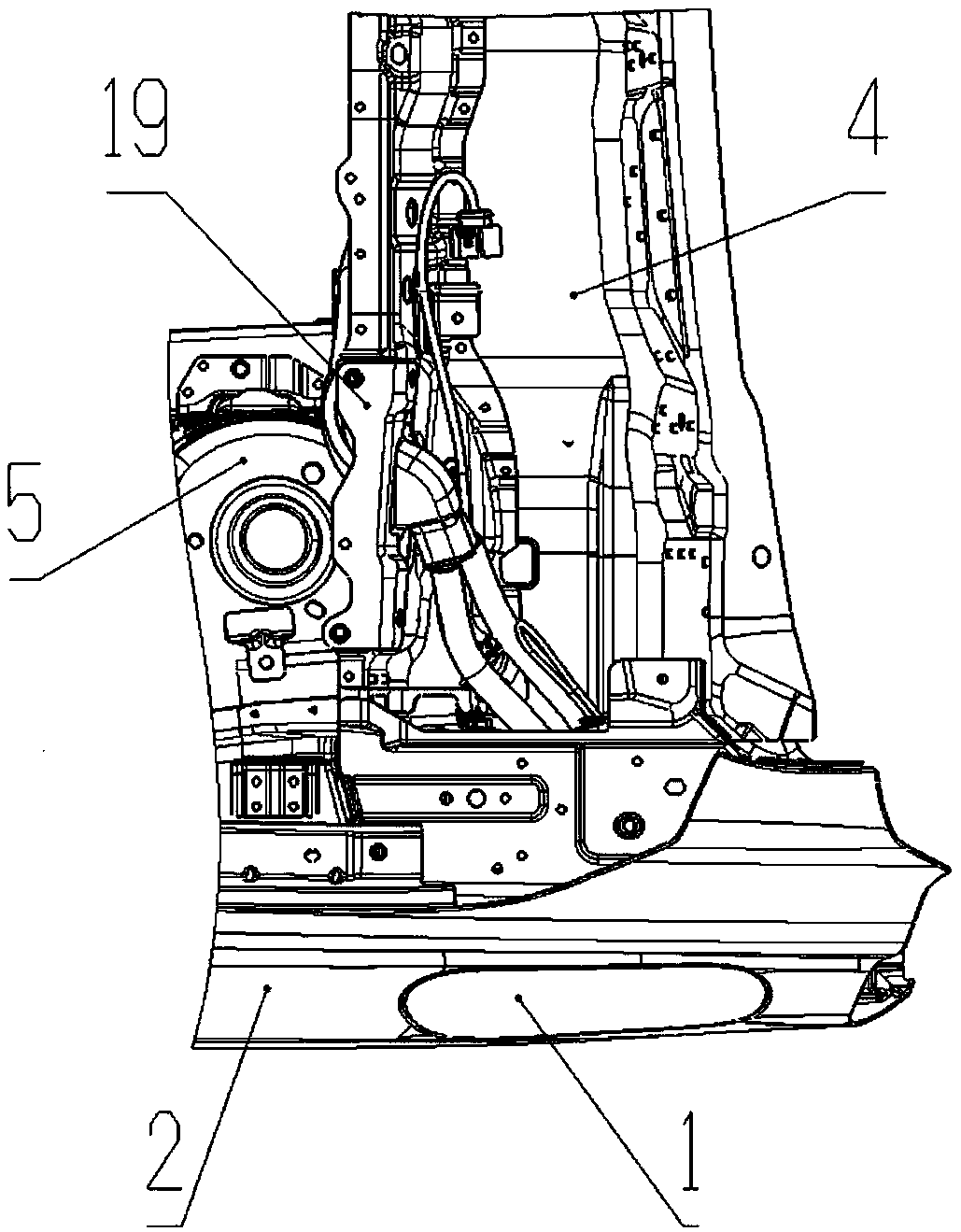

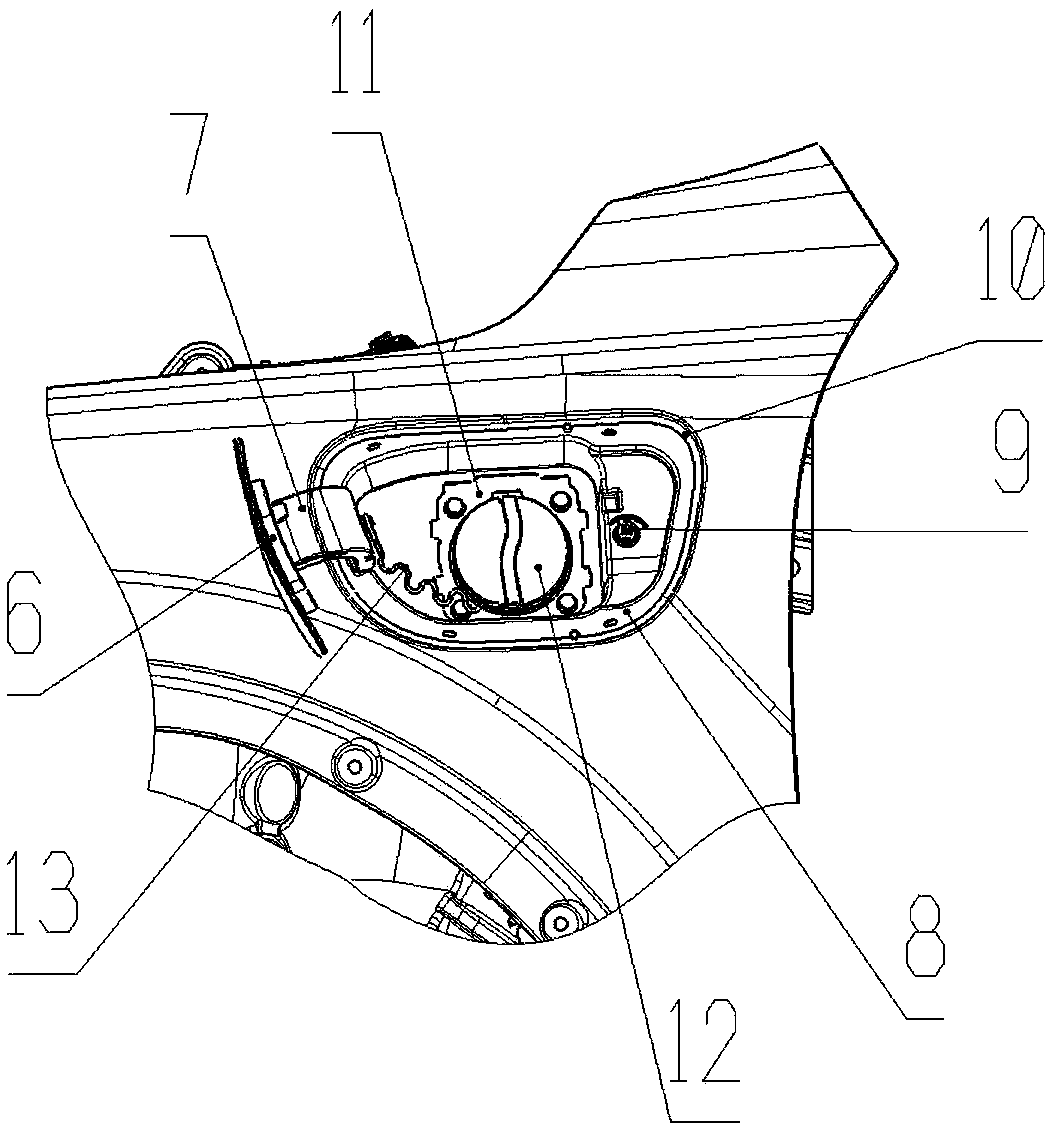

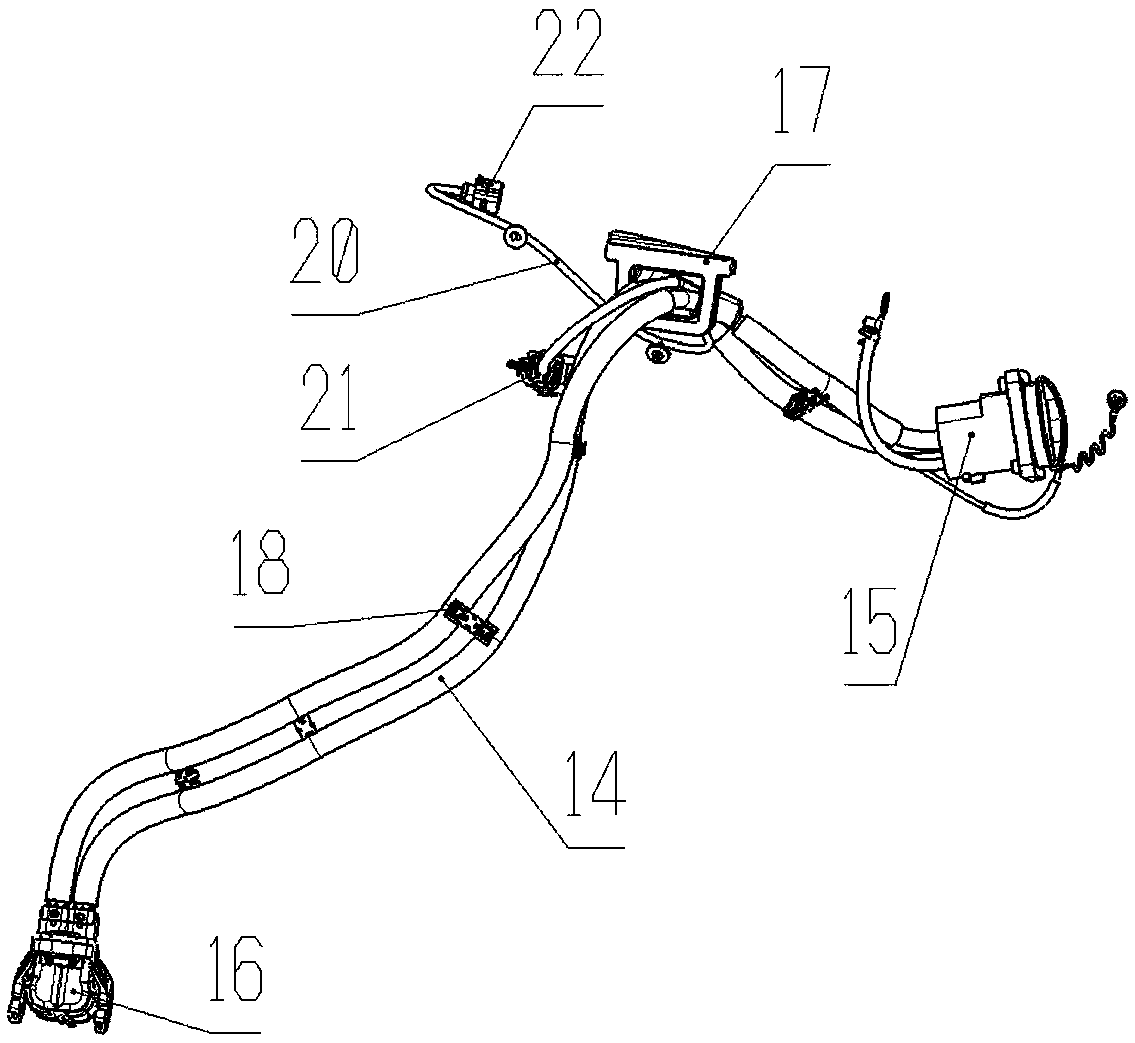

[0022] This embodiment provides an arrangement structure of the charging port and the high-voltage wire harness. On the one hand, it can be conveniently charged, and on the other hand, the length of the high-voltage wire bundle can be shortened without affecting the sealing of the passenger compartment, thereby saving costs.

[0023] An arrangement structure of a charging port and a high-voltage wire harness, including a charging port cover 1, a charging port fixing bracket 11, a charging port 15, a high-voltage wire harness 14, and a power battery connector 16;

[0024] The charging port cover 1 is arranged on the front fender 2 of the pure electric vehicle. Preferably, the front fender 2 is provided with a mounting hole, and the charging port cover 1 is snapped into the mounting hole; the charging port The fixing bracket 11 is fixedly connected with the vehicle body and is located at the bottom of the charging port cover 1; the charging port 15 is connected to the charging po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com