The structure and design method of the gate position of injection molded parts

A gate position and structure design technology, which is applied in the field of structure and design of the gate position of injection molded parts, can solve problems such as low strength, achieve the effects of prolonging service life, improving injection molding process performance, and stabilizing fluid pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

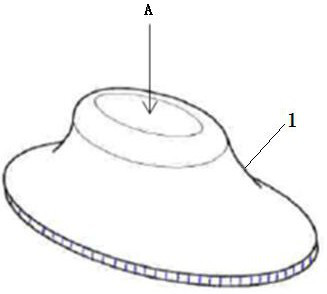

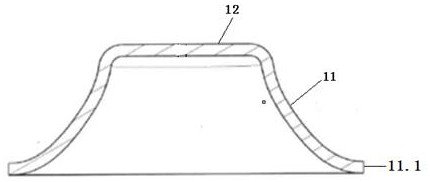

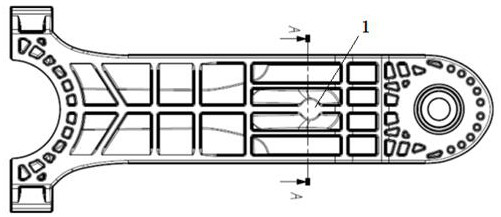

[0035] Combine below Figure 1 to Figure 4 Embodiments of the present invention are described in detail.

[0036] The structure of the gate position of the injection molded part is characterized in that the gate position of the injection molded part is a protruding structure 1 that protrudes outward, and the diameter of the protruding structure 1 gradually increases from the top to the bottom and the wall transitions smoothly It is a hollow tube without edges and corners, and the gate of the injection molded part is located on the top of the raised structure 1 .

[0037] As shown in the figure, the gate position of the injection molded part is designed as a convex structure 1 that protrudes outward, and the convex structure 1 is a hollow tube with a diameter gradually increasing from the top to the bottom and the wall transitions smoothly without corners, that is The raised structure 1 has the largest cross-sectional area close to other parts of the injection molded part, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com