A recycling material box device for cutting capacitor legs

A technology of reclaimed materials and capacitors, which is applied in the field of reclaimed material box devices for cutting capacitors, which can solve the problems of low work efficiency and increased burden on operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

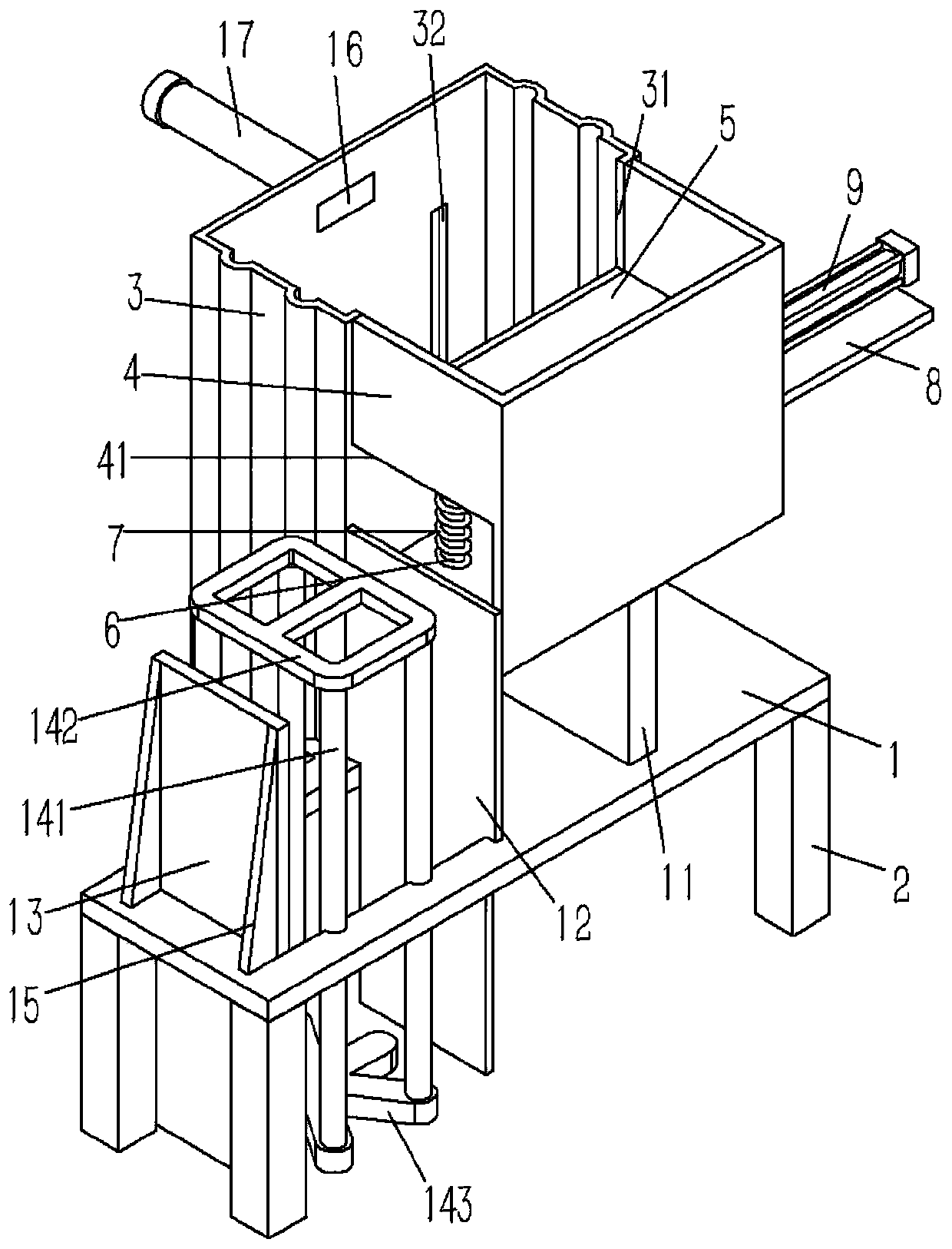

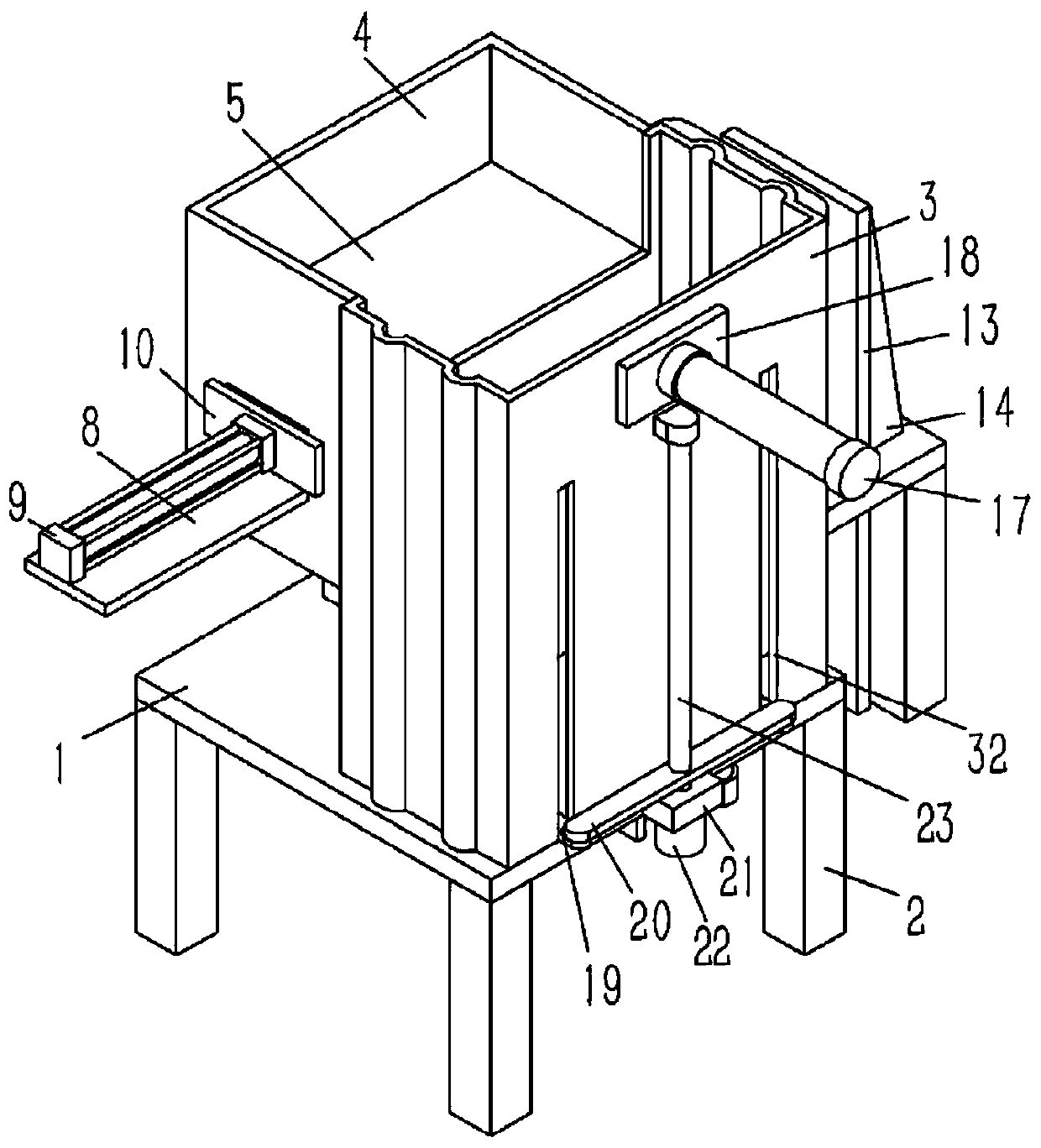

[0017] Example: see Figures 1 to 3 As shown, a recycling material box device for cutting the legs of a capacitor includes a base plate 1, a column 2 is fixed on the corner of the base plate 1, a vertical collection box material frame 3 is fixed on the base plate 1, and the collection box material frame 3 The upper end of the front end face is formed with a first outlet 31, and the front end face of the collection box material frame 3 around the first outlet 31 is fixed with a vertical charging material frame 4, and the charging material frame 4 is inserted with a supporting plate 5, and The bottom surface of the material frame 4 is plugged with some vertical T-shaped guide pillars 6, and the upper end of the T-shaped guide pillar 6 passes through the bottom plate of the charging material frame 4 and is fixed on the support plate 5. The T-shaped guide pillars The column 6 is inserted with a compression spring 7, and the two ends of the compression spring 7 are respectively pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com