Method and device for dispensing positioning based on machine vision

A technology of machine vision and positioning method, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of high cost, low efficiency, cumbersome steps, etc., achieve good positioning accuracy, reduce costs, and simple dispensing steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

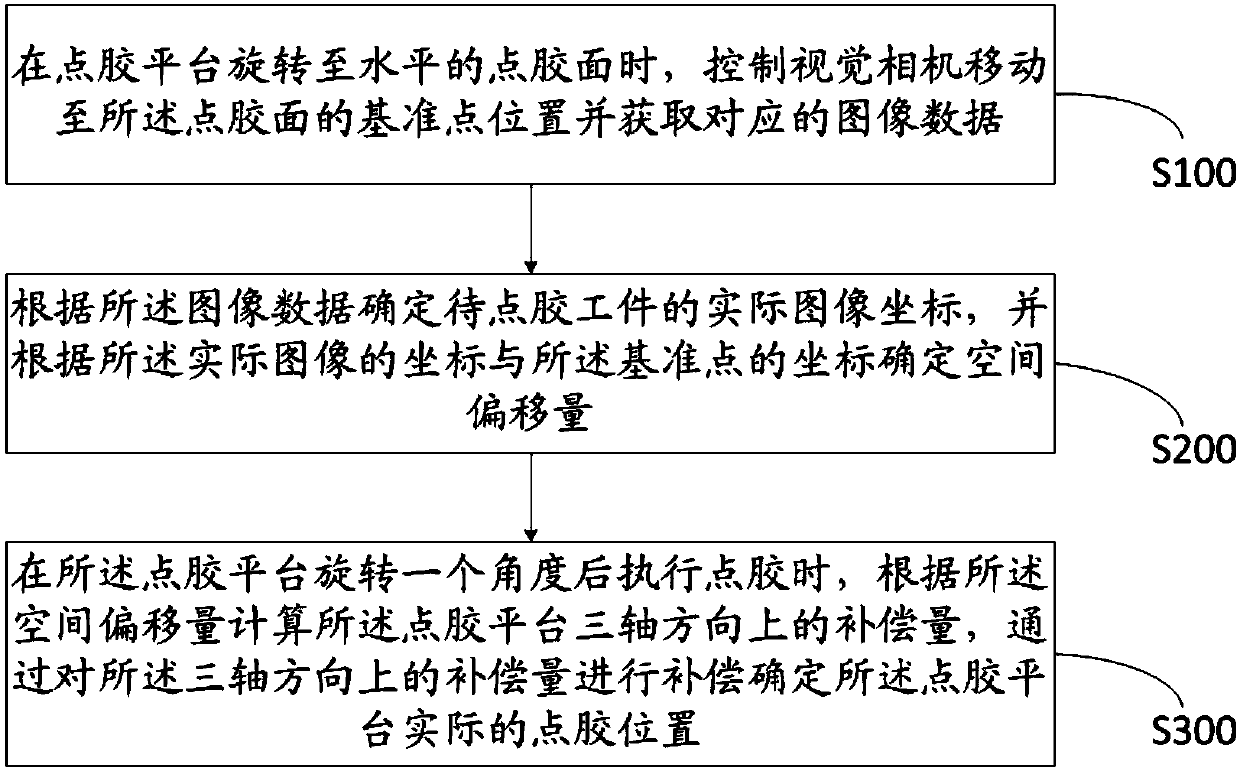

[0057] refer to figure 1 As shown, it is a flow chart of the steps of the machine vision-based dispensing positioning method described in the embodiment of the present invention, including the following steps:

[0058] S100: When the glue dispensing platform rotates to a horizontal glue dispensing surface, control the visual camera to move to a reference point position of the glue dispensing surface and acquire corresponding image data.

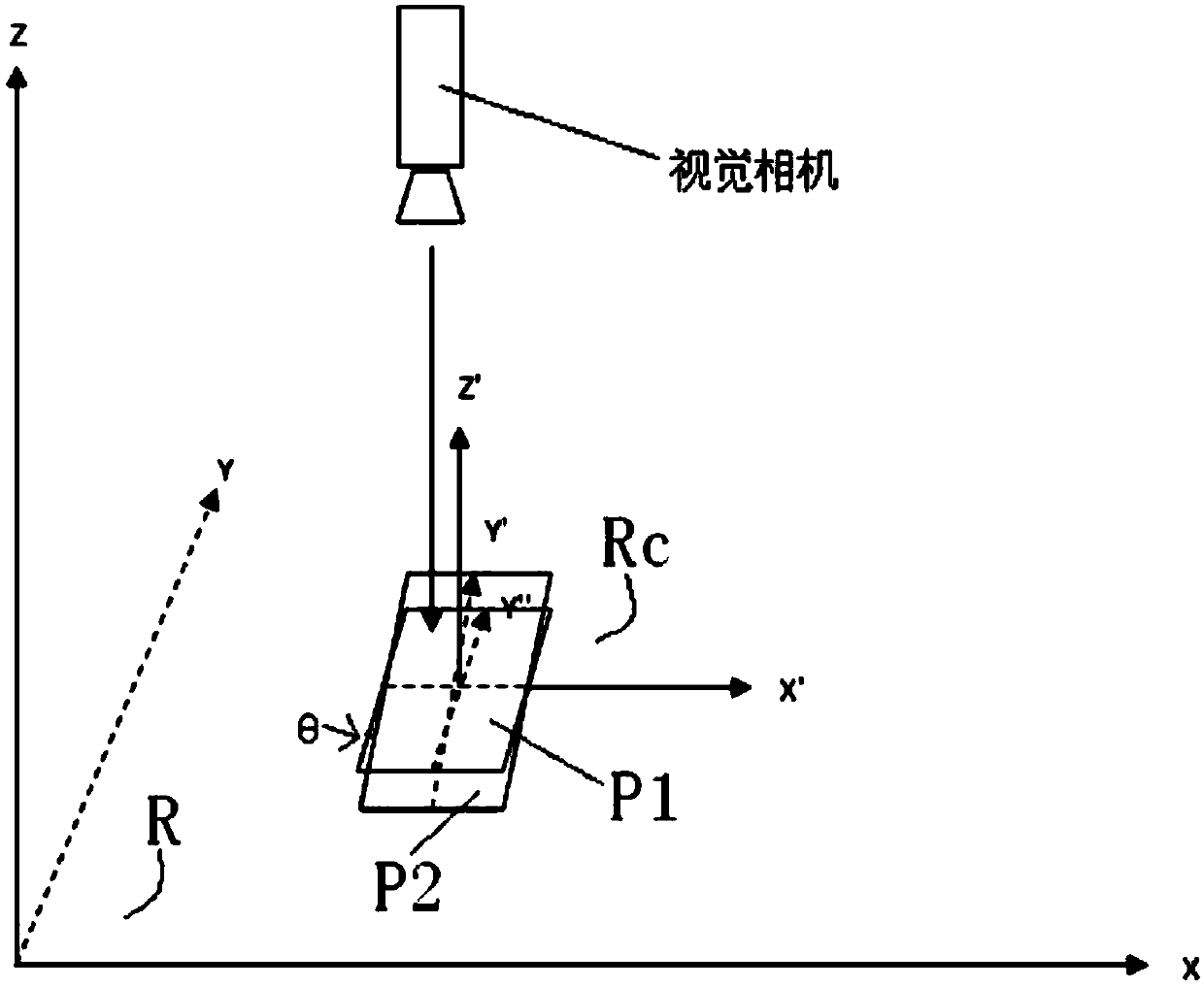

[0059] When the dispensing platform rotates to the horizontal dispensing surface, the visual camera is controlled to move to the reference point position of the dispensing surface. In this embodiment, the reference point position is the Mark point position of the dispensing surface of the workpiece to be dispensed. , that is, the point used for machine welding positioning; at this time, refer to figure 2 The coordinate schematic diagram of the dispensing positioning method shown, establishes a space Cartesian coordinate system R in the spac...

Embodiment 2

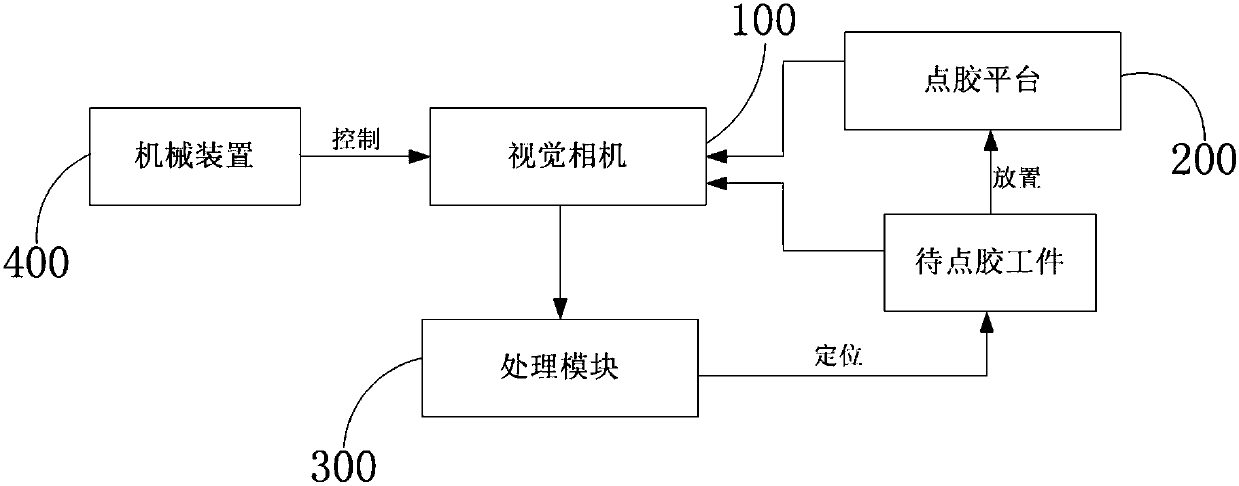

[0083] The embodiment of the present invention also provides a dispensing positioning device based on machine vision, which is applied to the dispensing positioning method based on machine vision described in the above embodiment. image 3 As shown, the dispensing positioning device includes a visual camera 100, a dispensing platform 200, a processing module 300 and a mechanical device 400 for controlling the movement of the visual camera;

[0084] The dispensing platform 200 is used to place workpieces to be dispensed; the visual camera 100 moves to the dispensing surface under the control of the mechanical device 400 when the dispensing platform 200 rotates to the horizontal dispensing surface Acquire corresponding image data at the reference point position; the processing module 300 is used to determine the actual image coordinates of the workpiece to be dispensed according to the image data obtained by the visual camera 100, and according to the coordinates of the actual im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com