Full-automatic field tray-paving device and tray-paving method thereof

A fully automatic, plate-laying technology, applied in the fields of botanical equipment and methods, filling of flower pots, gardening, etc., can solve the problems of aggravating labor, large labor demand, inability to achieve fixed-point plate-loading work, etc., and reduce labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing.

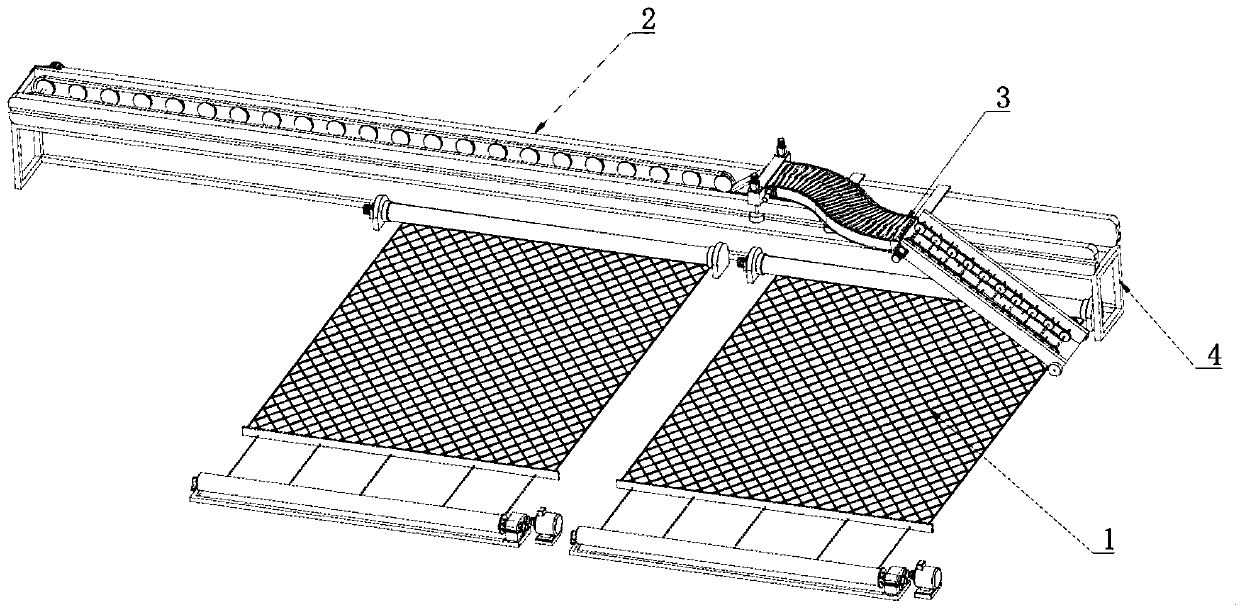

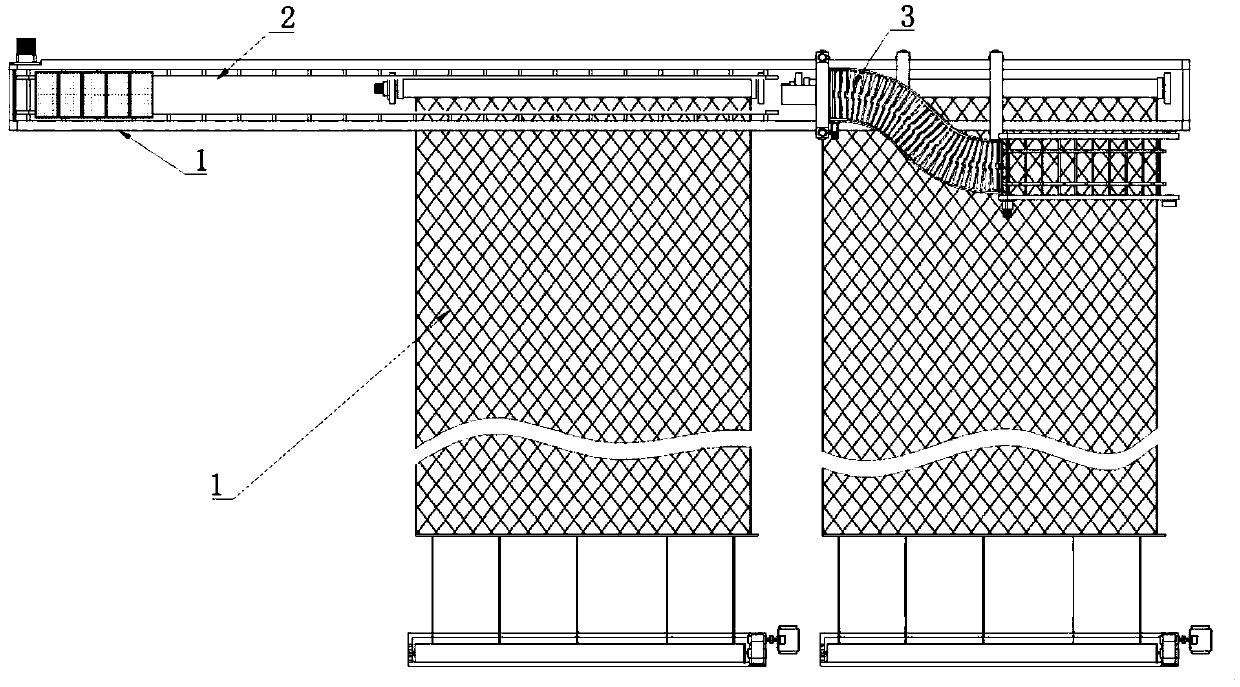

[0042] like figure 1 and 2 As shown, a fully automatic field spreading device includes a seedling raising tray output device and n film-covered spreading devices 1 . The n film-covered tray spreading devices 1 are respectively arranged on adjacent n rows of fields. The seedling tray output device is arranged on one end of the n ridge field (the actual number of n is determined according to the field ridge number of the paved field, in the present embodiment, for two ridge fields, so n=2).

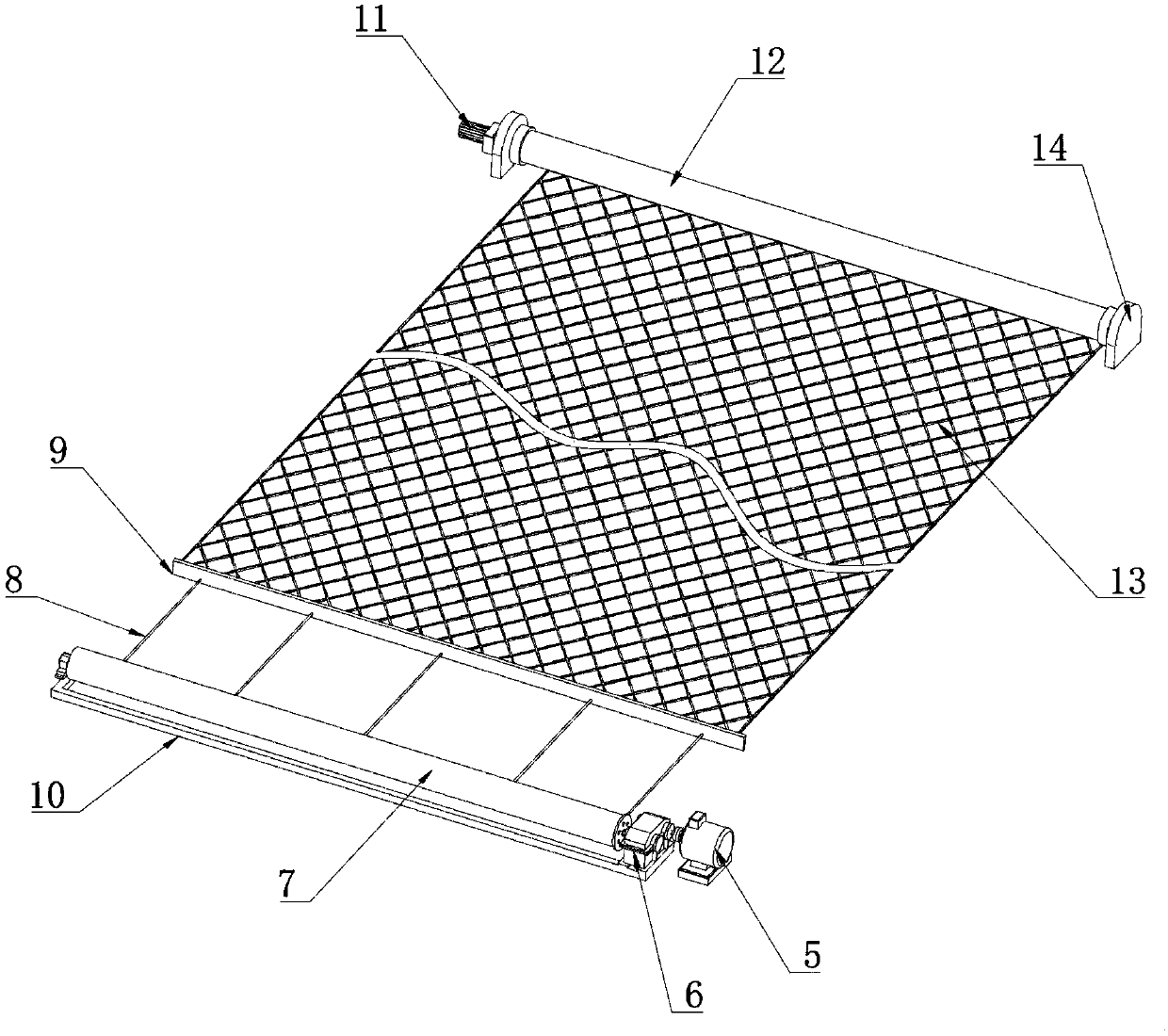

[0043] like figure 1 , 2 As shown in and 3 , the film laying device 1 includes a laying hoisting assembly and a film winding hoisting assembly. The spreading hoisting assembly and the film-winding hoisting assembly are respectively arranged at the two ends of the corresponding ridge field. The paving hoist assembly includes a paving reel 7, a rope 8, a film pulling plate 9, a pavin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com