A solar panel automatic framing machine

A technology of solar panels and framing machines, which is applied to circuits, electrical components, and photovoltaic power generation. The effect of frame precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

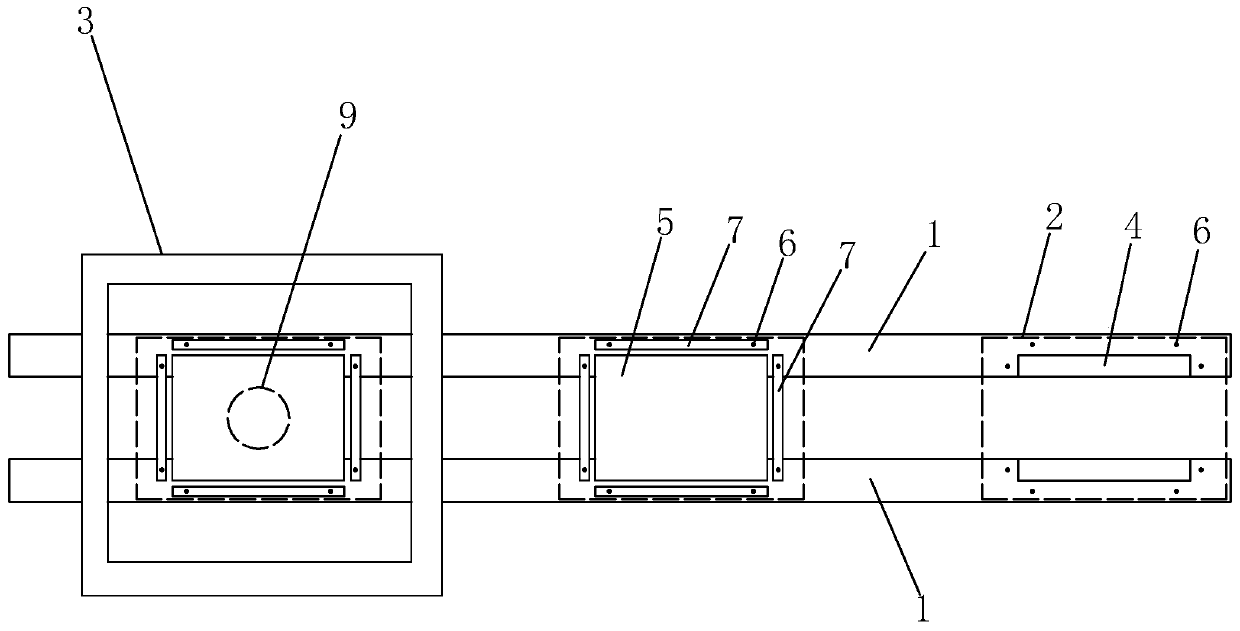

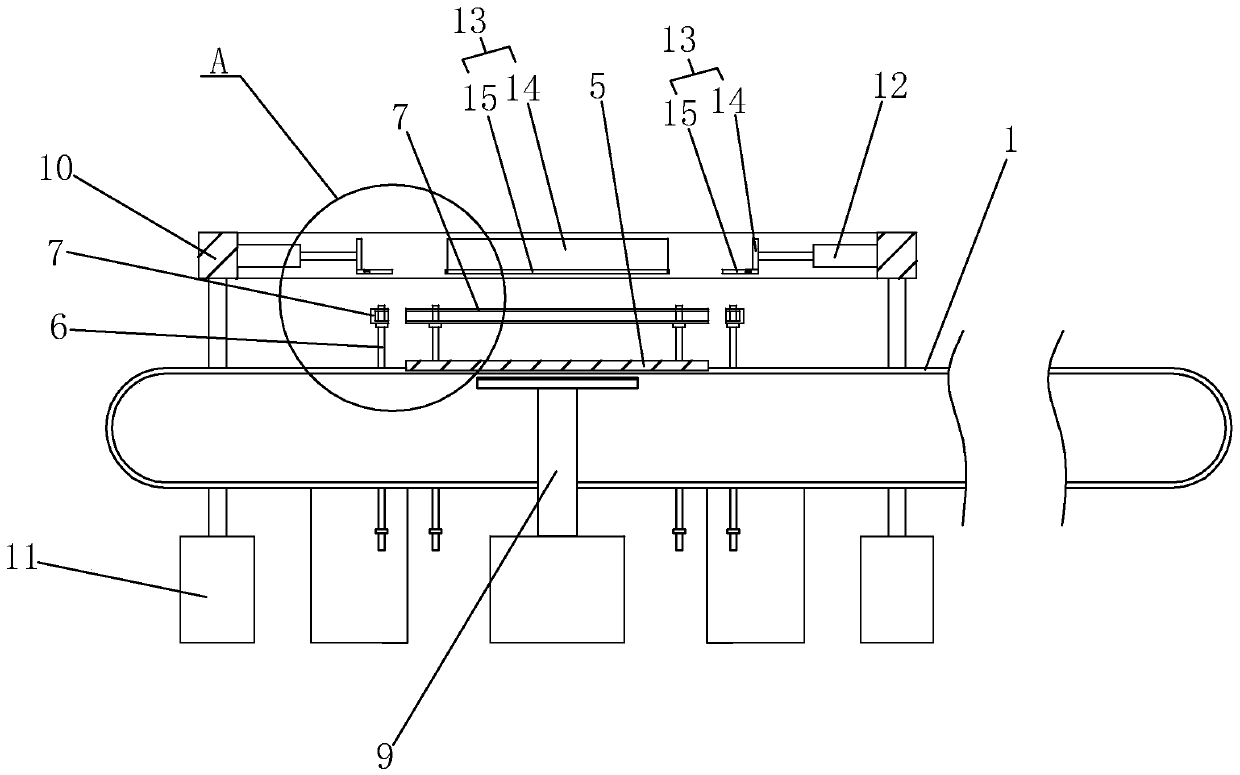

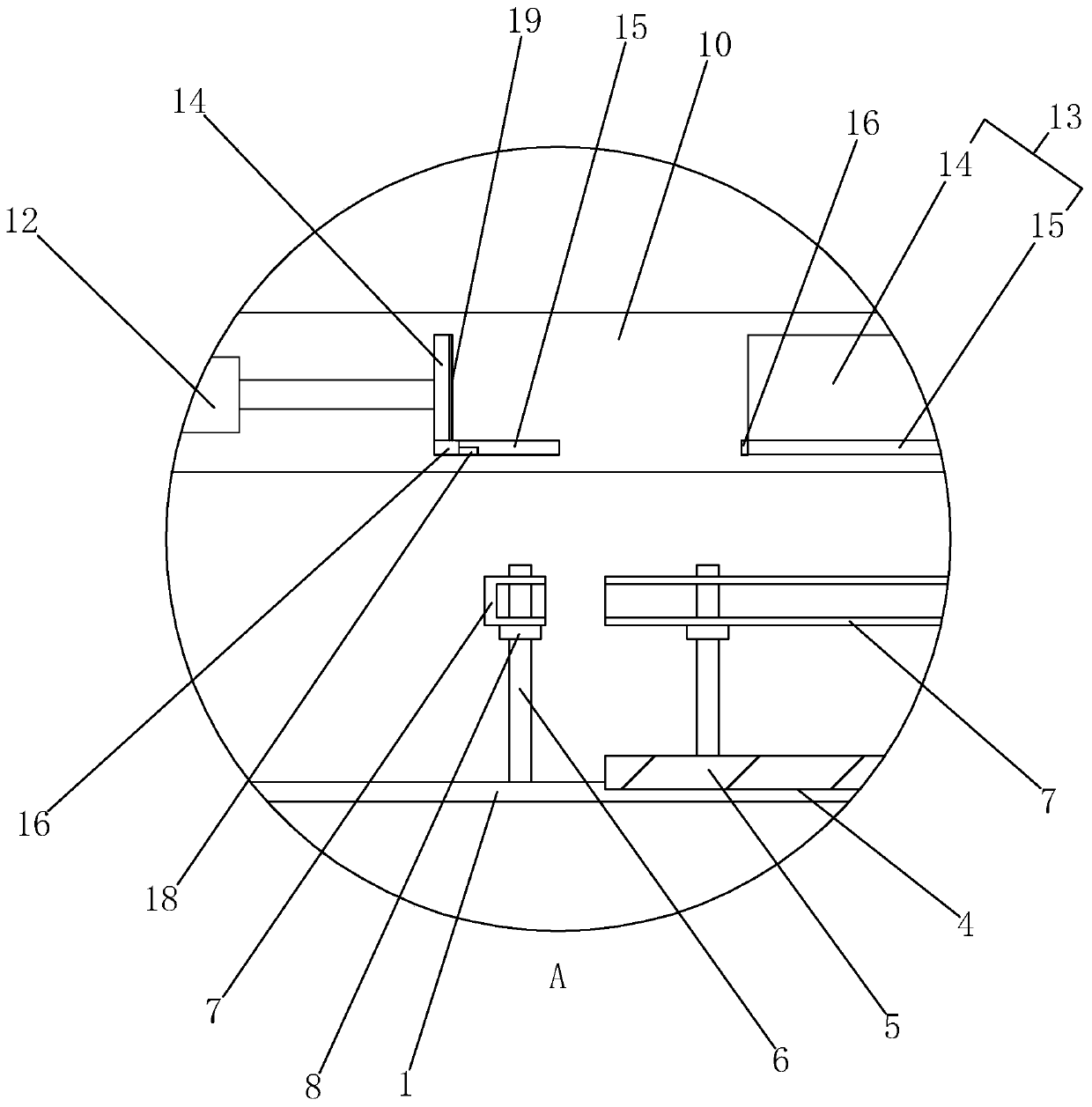

[0037] A solar panel automatic framing machine, such as figure 1 As shown, it includes two conveyor belts 1 arranged in parallel, and the two conveyor belts 1 run synchronously; the conveyor belt 1 is divided into several feeding units 2; During operation, the feeding unit 2 passes through the framing unit 3 in sequence.

[0038] Such as figure 1 As shown, each feeding unit 2 includes positioning slots 4 arranged on two conveyor belts, and solar panels 5 are transported across the positioning slots 4 placed on the two conveyor belts 1; When the solar cell panel 5 is placed in the positioning groove 4, every two fixed rods 6 correspond to one side of the solar cell panel 5 and are respectively located on both sides of the side. The fixed rods 6 are used for setting The glued frame 7 ; correspondingly, the frame 7 is also provided with a through hole 20 for matching with the fixing rod 6 . The above-mentioned conveyor belt 1 is a metal track, and the fixed rod 6 is welded and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap