A method for quantitatively detecting three-dimensional defects inside equipment

A quantitative detection and defect technology, used in material defect testing and other directions, can solve the problems of low quantitative detection level and affect the accuracy of quantitative verification, and achieve the effect of improving anti-interference ability and high detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

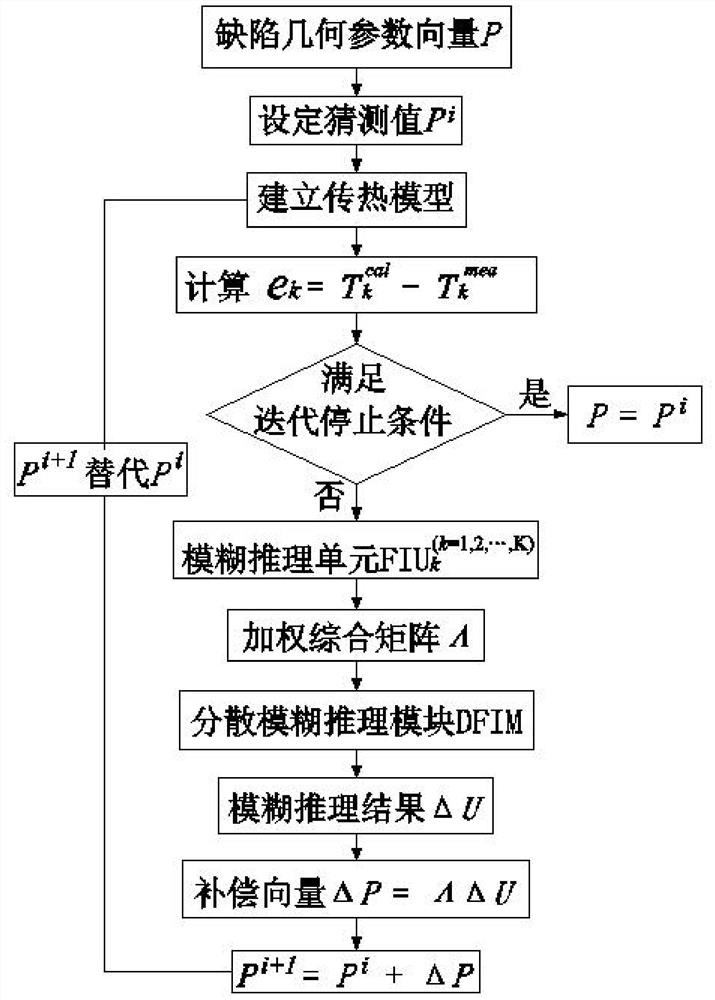

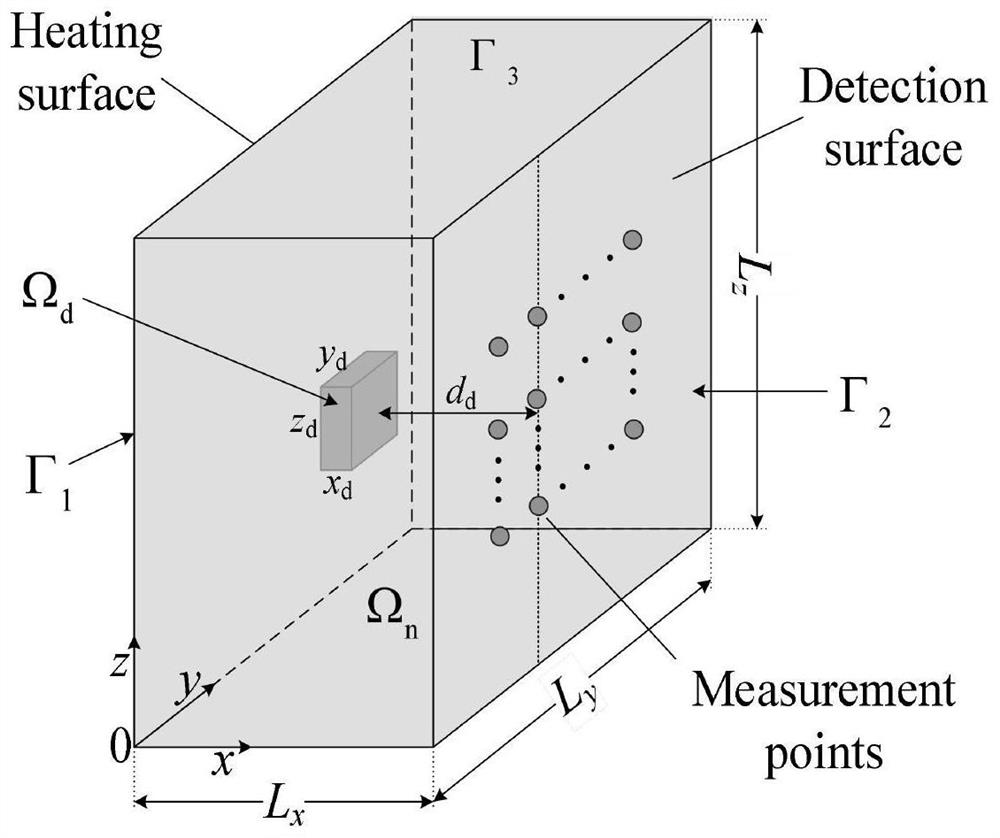

[0025] join Figure 1-5 , a method for quantitatively detecting three-dimensional defects inside a device in a specific embodiment, the length, width and height of the selected shape are respectively L x , L y , L z As the tested object, the test piece of the embodiment has a three-dimensional defect inside, and the detection includes the following steps:

[0026] 1) Select K temperature sampling points on the measurement surface of the test piece, and set the guess value P of the defect geometric parameter vector P i , where i is the number of iterations;

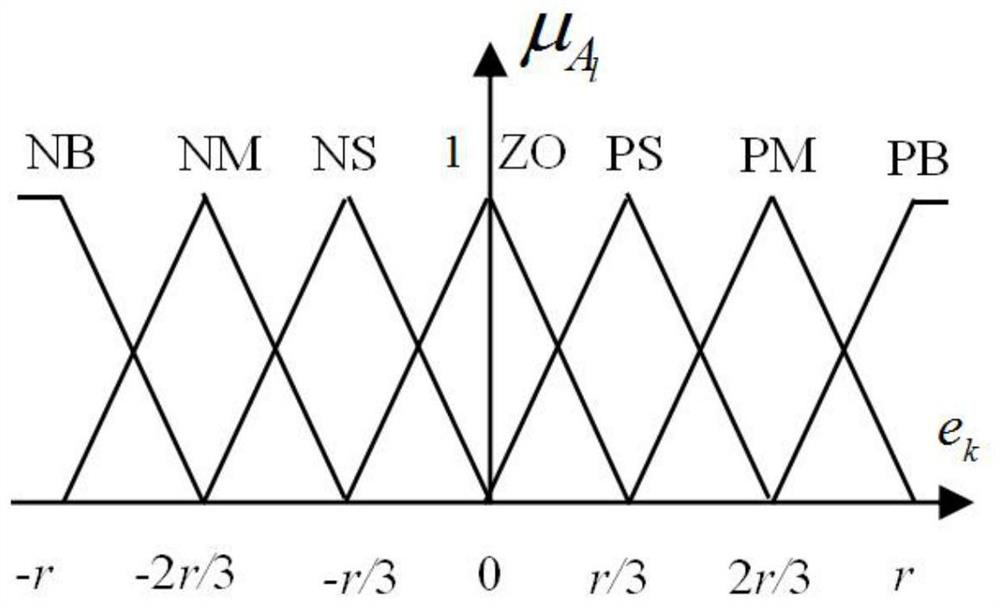

[0027] 2) According to the guessed value P of the defect geometric parameter vector P i , establish the heat transfer model of the test piece with internal defects; according to the heat transfer model, use the finite element method (FEM) to calculate the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| film coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com