Liquid sampling device capable of buoyancy stratified sampling and automatic cleaning for chemical industry

An automatic cleaning and liquid sampling technology, which is applied in the direction of sampling device and test sample preparation, etc., can solve the problems of separate sampling work, liquid scattering, affecting the working environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

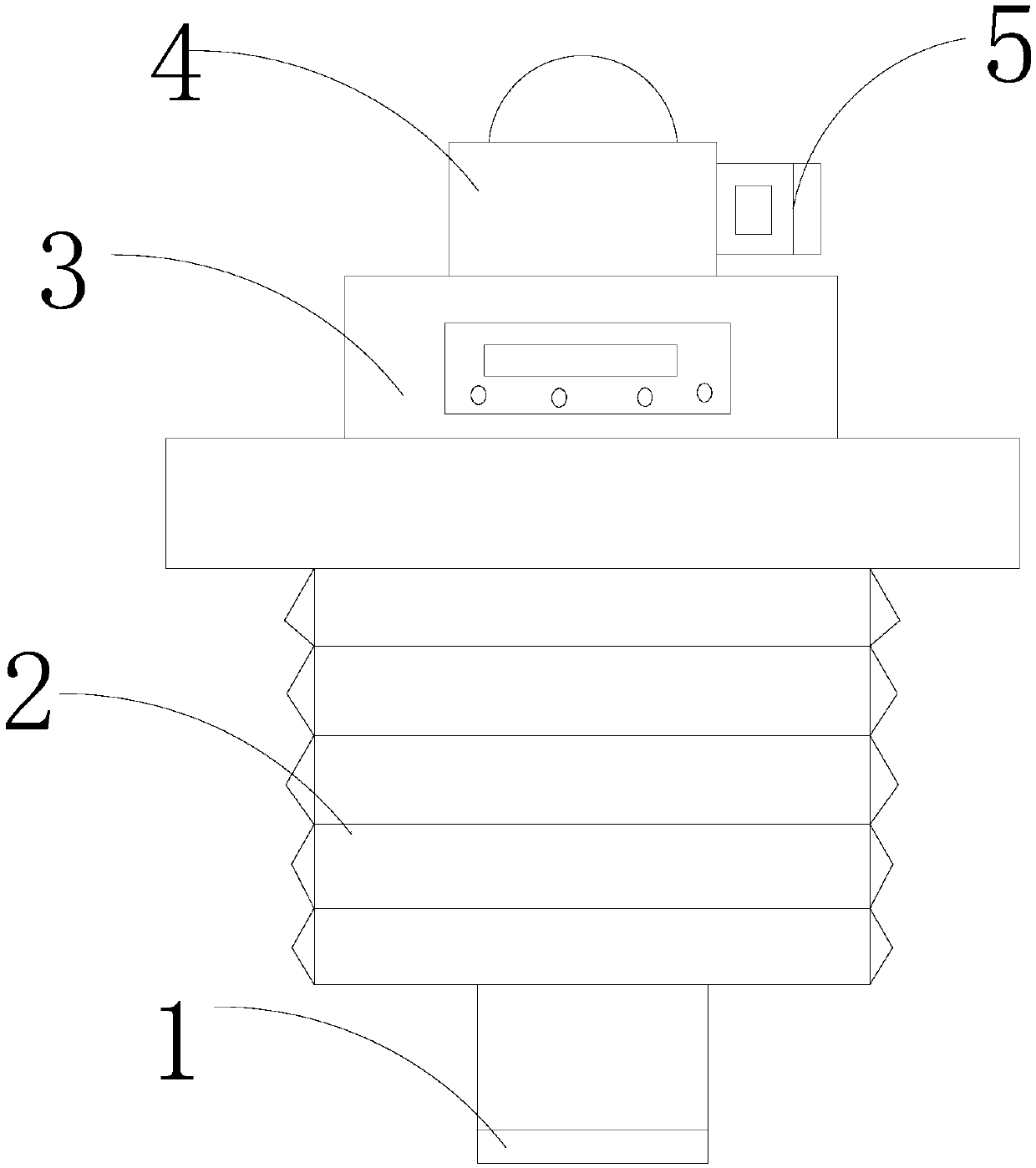

[0028] see figure 1 , the present invention provides a liquid sampling device for chemical industry that can be automatically cleaned by layered sampling with buoyancy. Its structure includes: a movable frame 1, a threaded layer 2, an intelligent sampling device 3, a device housing 4, and a motor frame 5. The motor frame 5 is located on the right end face of the device housing 4 and is connected to the device housing 4 at the same time. The intelligent sampling device 3 is fixedly connected to the inside of the device housing 4. The threaded layer 2 is located in the device housing. Both of the outer end faces of 4 are integrated structures, the movable frame 1 is located at the bottom end of the device housing 4 and is movably connected with the device housing 4, the outer end face of the device housing 4 is provided with a control module, through The control module integrates and regulates the internal devices.

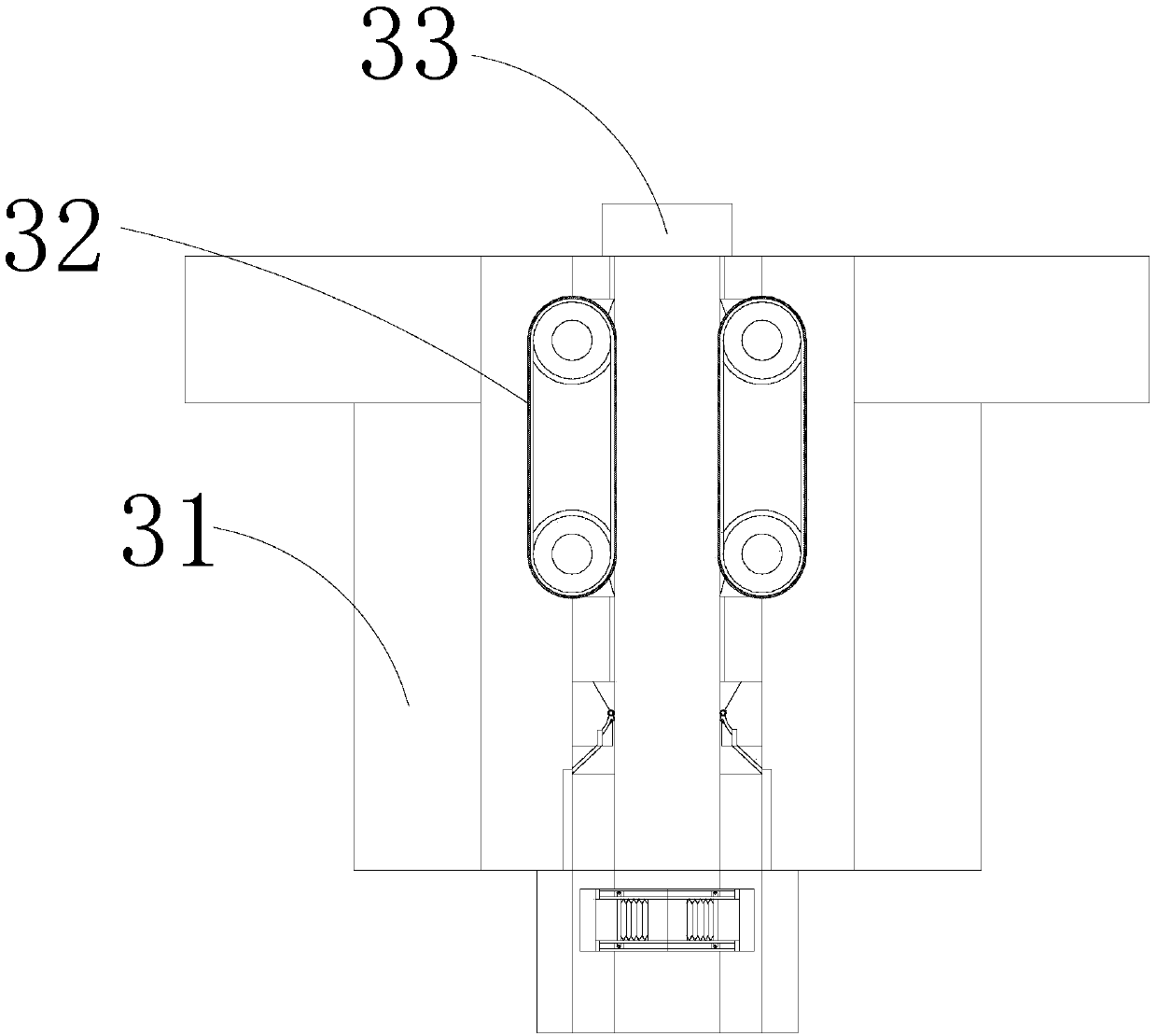

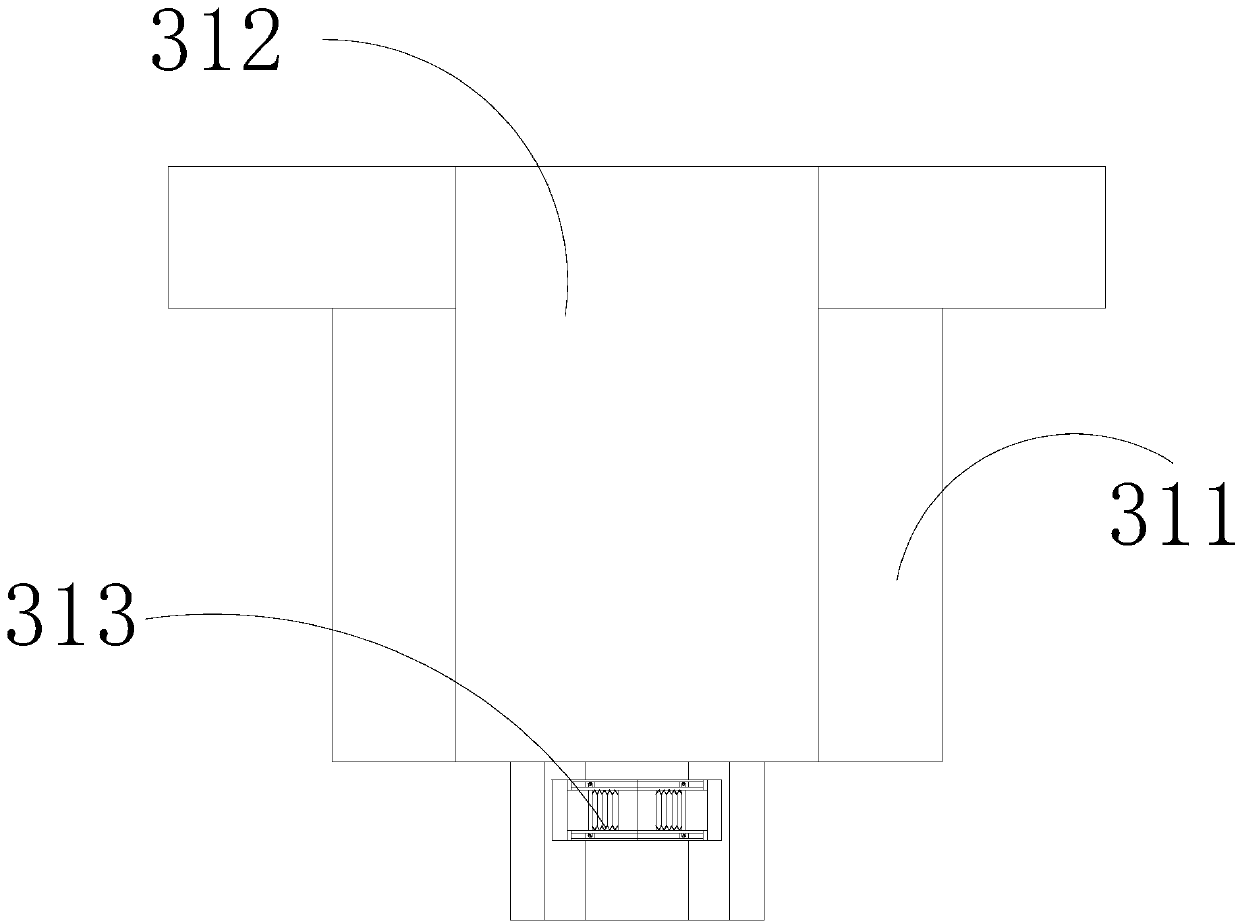

[0029] see figure 2 , the present invention provides a liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com