Large portal crane load test device and method

A technology of load test and door crane, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of high cost of experiments, waste of resources, and heavy test configuration, so as to facilitate popularization and use, avoid waste of resources, The effect of reducing the test procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

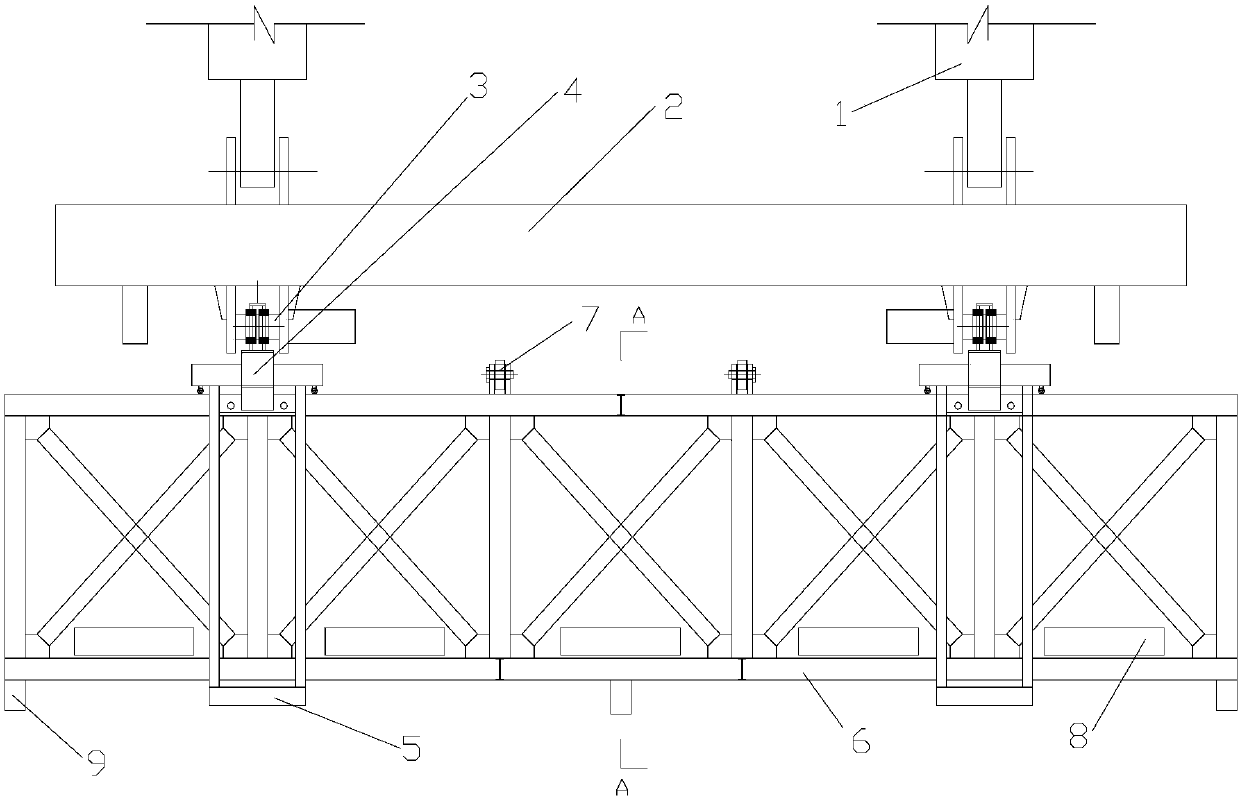

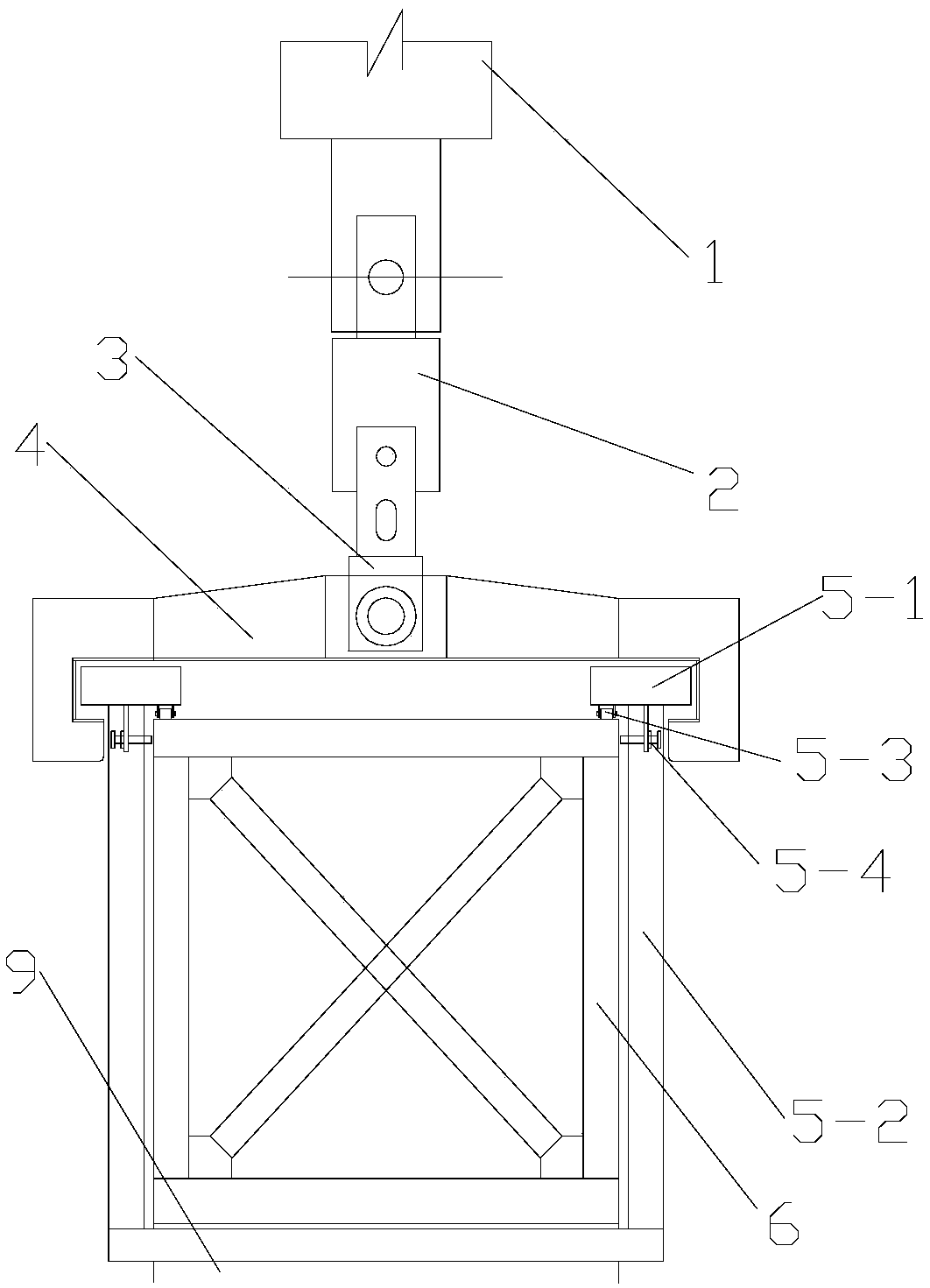

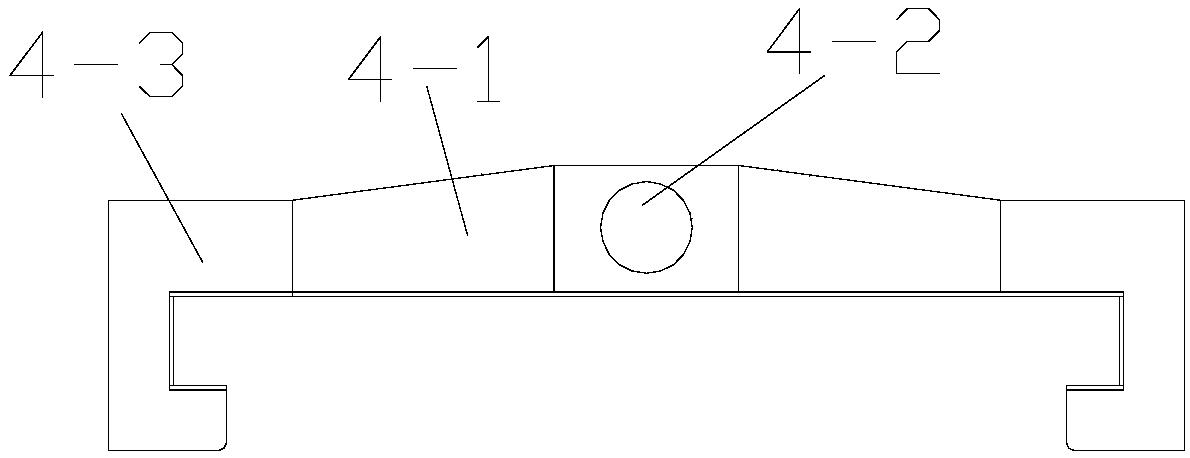

[0049] Such as Figure 1 to Figure 4 As shown, the load test device for a large-scale portal crane according to the present invention includes a main test hanger 6 for bearing test counterweight 8, an outer sliding hanger 5 installed outside the main test hanger 6, and The balance beam 4 outside the sliding hanger 5 and connected with the automatic grab beam 2 of the door machine. The bottom of the test main hanger 6 is installed with a limit mechanism 9 for limiting the moving position of the outer sliding hanger 5, and the door machine automatically grabs the beam The bottom of the 2 is provided with a balance beam connecting pin 3, the top of the automatic grab beam 2 of the door machine is matched with the door motorized pulley group 1. The test main hanger 6 is a cube frame, and the front side, rear side, and left side of the cube frame The upper surface, the right side and the bottom surface are all installed with diagonal supports arranged to cross each other. The top sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com