LED light emitting chip hybrid gear dividing method and application method of light emitting chip

A light-emitting chip and hybrid technology, which is applied in the direction of optical instrument testing, optical performance testing, machine/structural component testing, etc., can solve the problems of many types of LED light-emitting chips, difficulty in merging, and difficulty in management, so as to ensure consistent color purity The effect of high consistency of sex and color purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

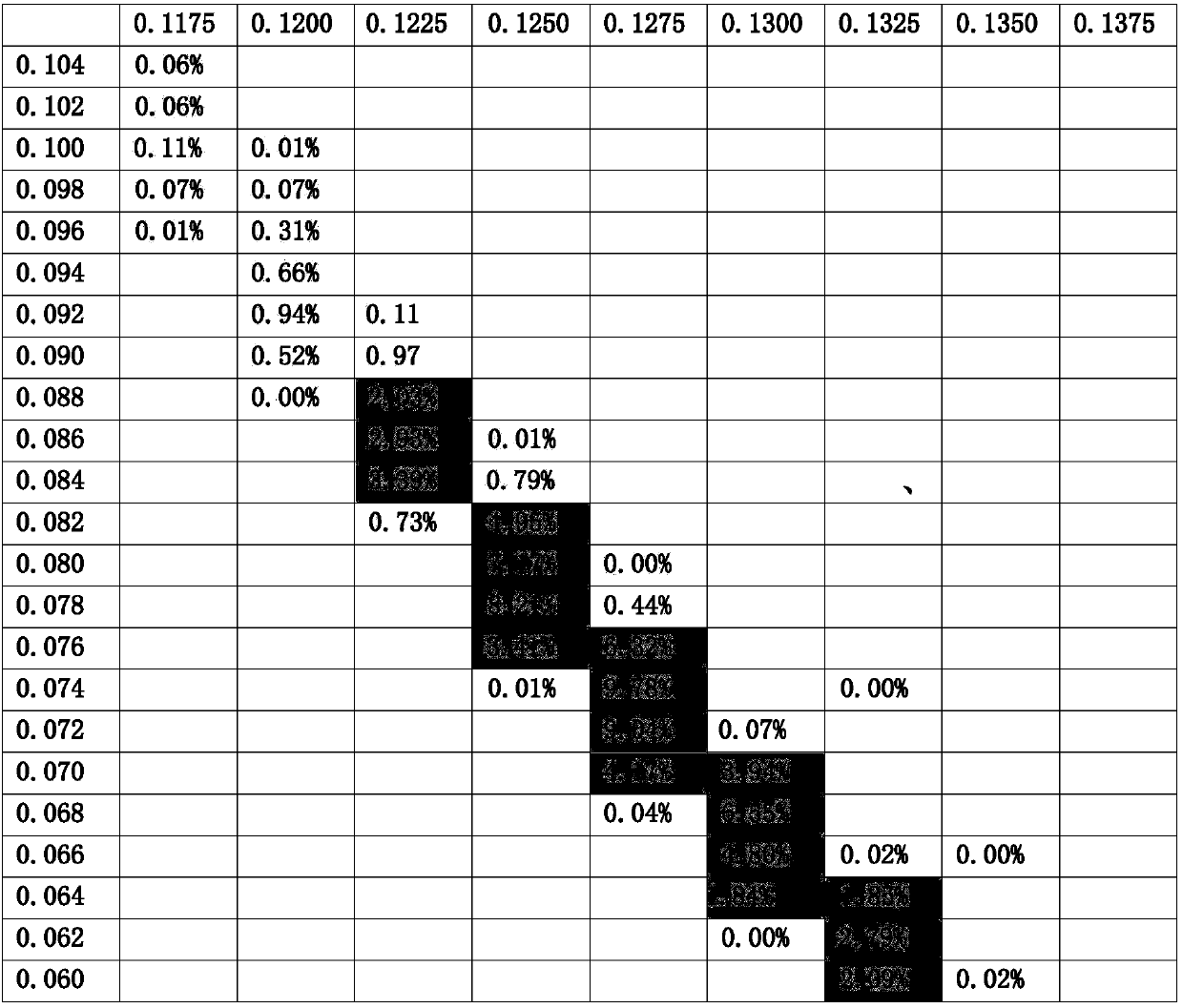

[0046] As shown in Table 1, the first row of numbers represents the upper limit of the x-color coordinates of each gear of the green light-emitting chip, and the x-color coordinate range of each gear is G[x i ~x j ]=0.006; the first column of numbers represents the upper limit of the y color coordinates of each gear of the green light-emitting chip, and the range of the y color coordinates of each gear is G[y i ~y j ]=0.013; there are 9 main stalls of green light-emitting chips; as shown in Table 2, the scattered green light-emitting chips whose x color coordinate is less than or equal to 0.132 are merged into merged file 10, and the scattered green light-emitting chips whose x color coordinate is greater than 0.132 Light-emitting chips are merged into merged file 11. As shown in Table 3, the first row of numbers represents the upper limit of the x color coordinates of each gear of the blue light-emitting chip, and the x color coordinate range of each gear is B[x i ~x j ]=...

Embodiment 2

[0048] When making the display screen, if the green light-emitting chips of the same main file in Table 1 are selected, the blue light-emitting chips of adjacent 2-3 main files in Table 3 can ensure that the green light of the display screen has good consistency and the blue light color is uniform Transitional change.

Embodiment 3

[0050] When making a display screen, select the green light-emitting chip in the merged file 10 or the merged file 11 in Table 2, and select the blue light-emitting chip in the merged file 21 or the merged file 22 in Table 4. Such a display screen has low color purity, but after sufficient There will be no obvious color lumps when stirring. Suitable for low-end display market. The application problem of scattered light-emitting chips is solved.

[0051] Table 1 The proportion of each gear after the green light-emitting chip of a certain specification is graded according to the color coordinates

[0052]

[0053] Table 2 Percentage ranking table of each grade after the green light-emitting chip of a certain specification is graded according to the color coordinates

[0054]

[0055] Table 3 The proportion of each gear after the blue light-emitting chip of a certain specification is graded according to the color coordinates

[0056]

[0057]

[0058] Table 4 Sorti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com