Optical fiber conical sensing probe head based on surface plasmon resonance and manufacturing method thereof

A technology of surface plasmon and sensing probes, which is applied in the direction of transmitting sensing components, converting sensor output, and measuring devices with optical devices, can solve problems such as difficulty in use, large volume, and complex structure of optical fiber sensors, and achieve simple structure, Improved sensitivity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

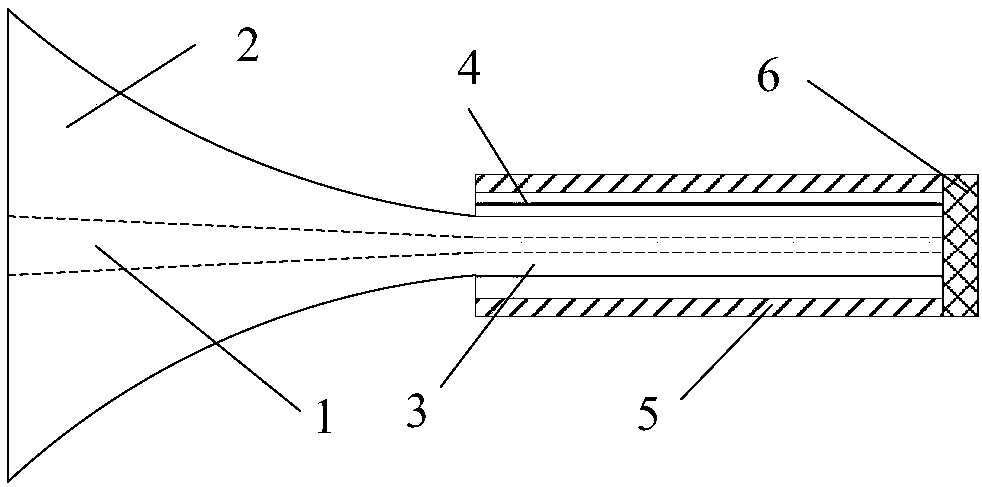

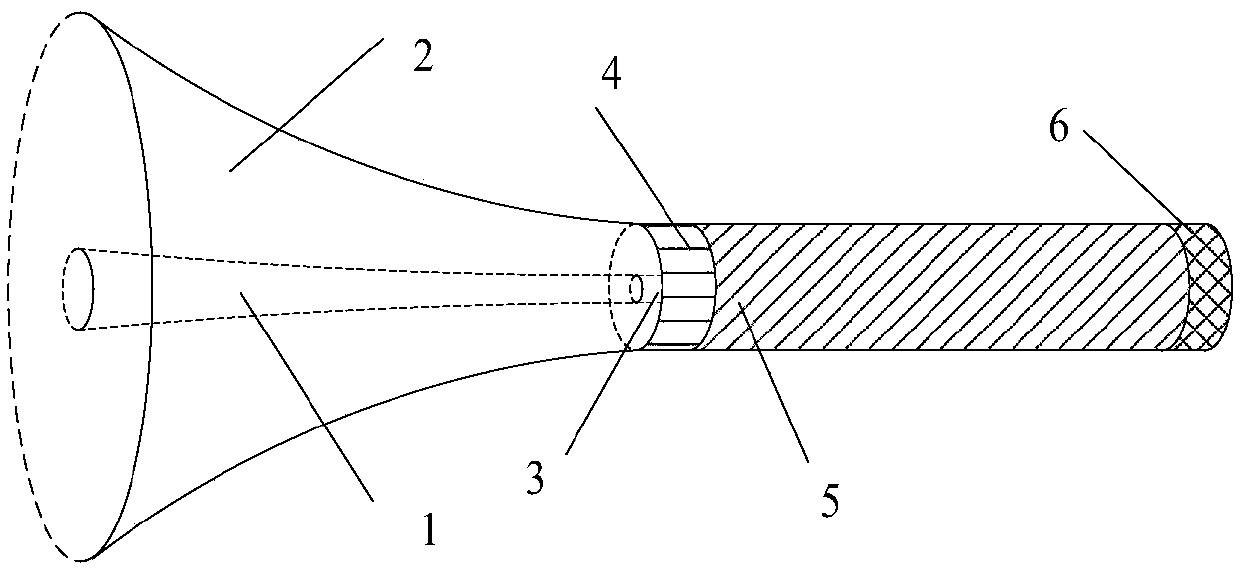

[0037] Such as figure 1 , figure 2 As shown, the present invention discloses a fiber optic tapered sensing probe based on surface plasmon resonance, which includes a single-mode fiber, a metal-metal oxide composite film, a sensitive film, and a metal reflection film; wherein, the end of the single-mode fiber The fiber core is stretched into a tapered probe; the metal-metal oxide composite film is covered on the tapered waist surface of the tapered probe to improve the sensitivity of the tapered sensing probe; the sensitive film is covered on the metal-metal oxide The surface of the compound film is used for sensing the measured signal; the metal reflective film is arranged on the end face of the end of the tapered probe to form a micro mirror for reflecting the measured signal.

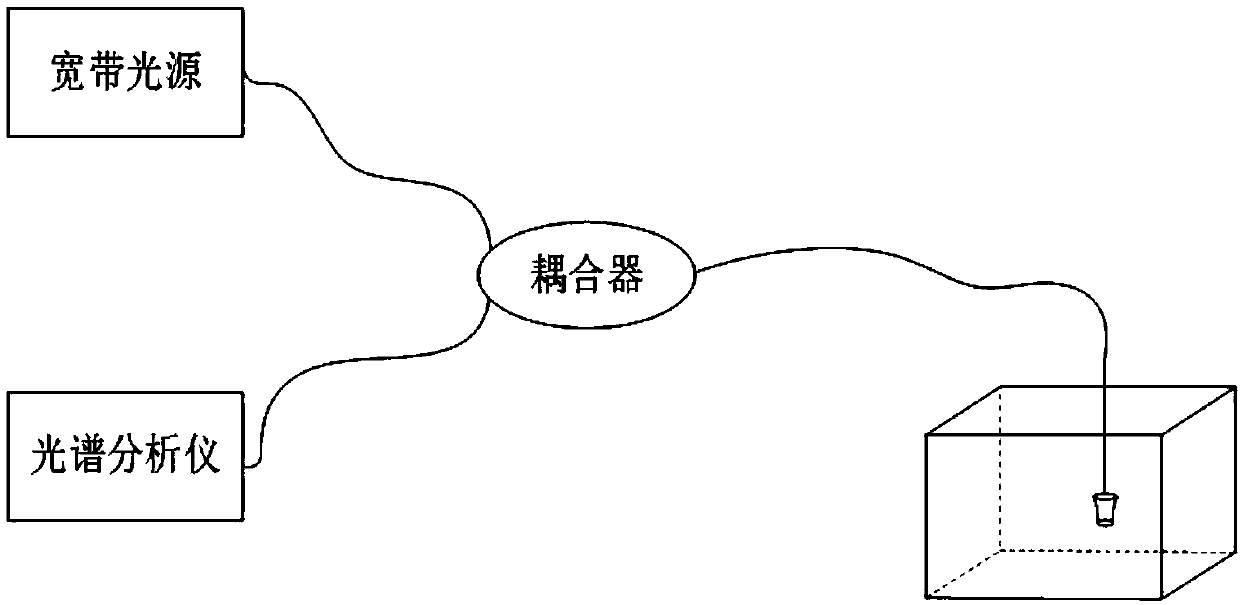

[0038] The invention also discloses a method for making the optica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com