Assembled prestressed large plate inverted-camber self-adjusting system and using method thereof

A prestressed and self-adjusting technology, applied in the processing of floor slabs, building materials, construction, etc., can solve the problem of over-camber of prefabricated large slabs, reduce the operation of on-site workers, have good construction effect, and achieve a high degree of automation. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

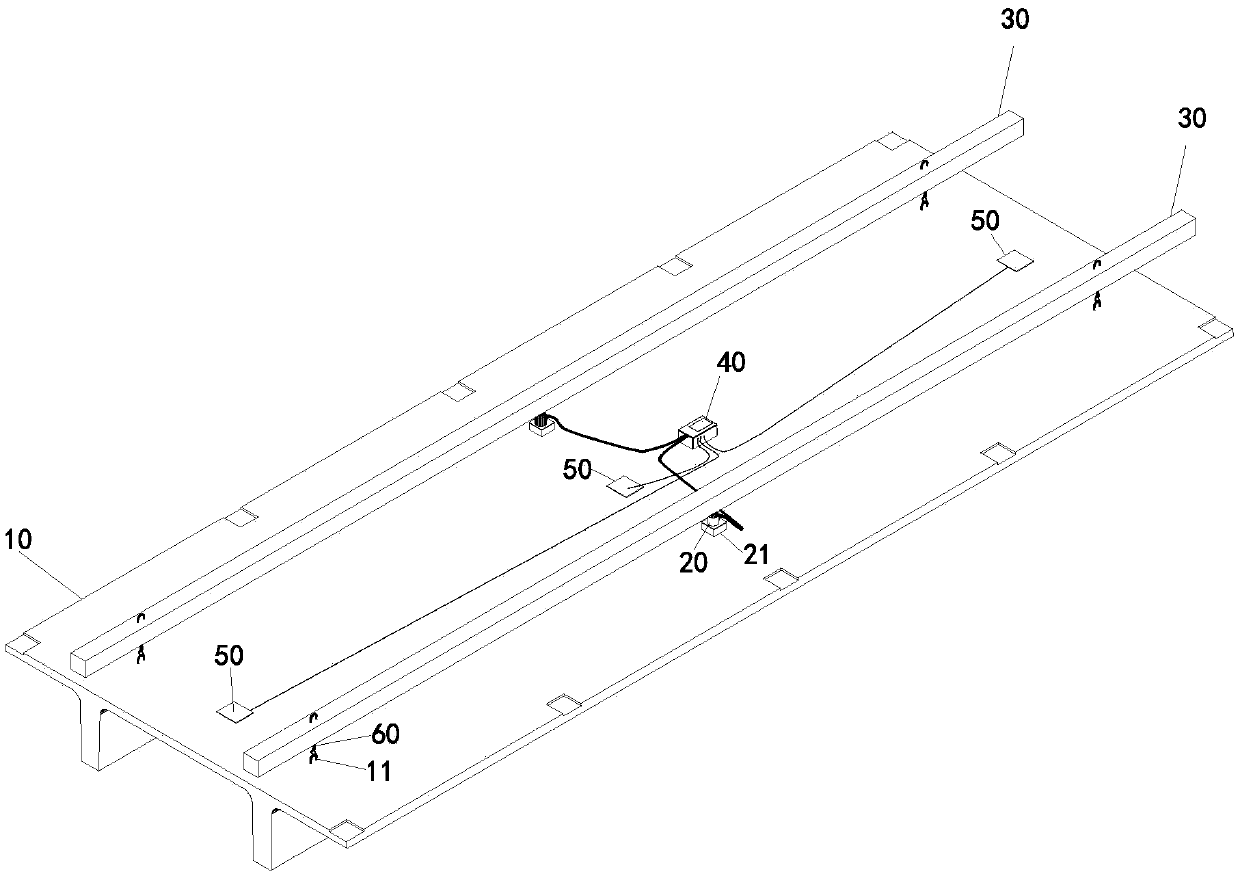

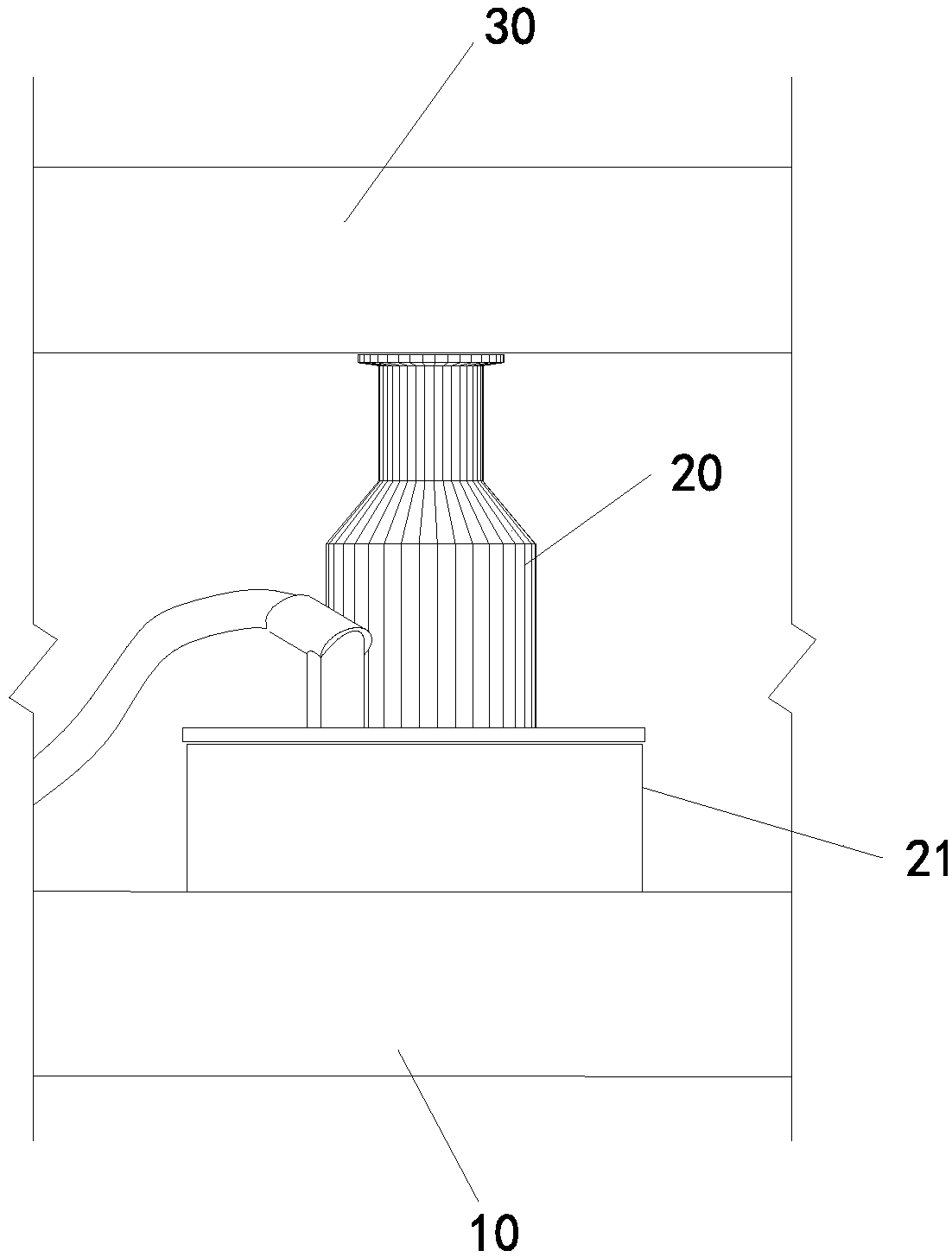

[0039] This embodiment provides an assembled prestressed slab anti-camber self-adjusting system, combined below Figure 1 to Figure 5 The system is described further. The system includes a hydraulic loading device 20 , a reaction force frame 30 , an adjustment control reactor 40 and several camber measuring sheets 50 .

[0040] Wherein, the reaction force frame 30 is arranged along the length direction of the prestressed plate 10, and the two ends are connected with the hanging points 11 at the ends of the prestressed plate 10 through flexible connectors 60. The hydraulic loading device 20 is arranged under the middle part of the reaction force frame 30. A spacer 21 is provided between the loading device 20 and the prestressed plate 10 . The camber measuring sheet 50 is arranged along the length direction of the prestressed slab 10 , and is connected to the adjustment control reactor 40 with a signal, and is used for measuring the camber value of the prestressed slab 10 . Th...

Embodiment 2

[0048] This embodiment provides a method of using the self-adjusting system for the camber of the assembled prestressed large slab described in Embodiment 1, combined below Figure 1 to Figure 5 This method of use is further introduced. The method of use specifically includes:

[0049] Step 1: Arrange a number of camber measuring points on the hoisted prestressed slab 10, install the camber measuring piece 50 and the adjustment control reactor 40, and send the camber measuring piece 50 and the adjustment control reactor 40 signal connect.

[0050] At least three camber measuring pieces 50 are arranged on the prestressed slab 10 , one of which is located at the middle of the prestressed slab 10 along the lengthwise direction, and two of them are located at the two ends of the prestressed slab 10 along the lengthwise direction. Of course, it is also possible to add a camber test piece 50 between the three camber test pieces 50 to better collect the camber data of the prestress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com