Assembly type partition wall connecting member and using method thereof

A prefabricated, connecting piece technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of unadjustable connection length and connection stress, interface peeling at the connection of partition walls, penetration cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

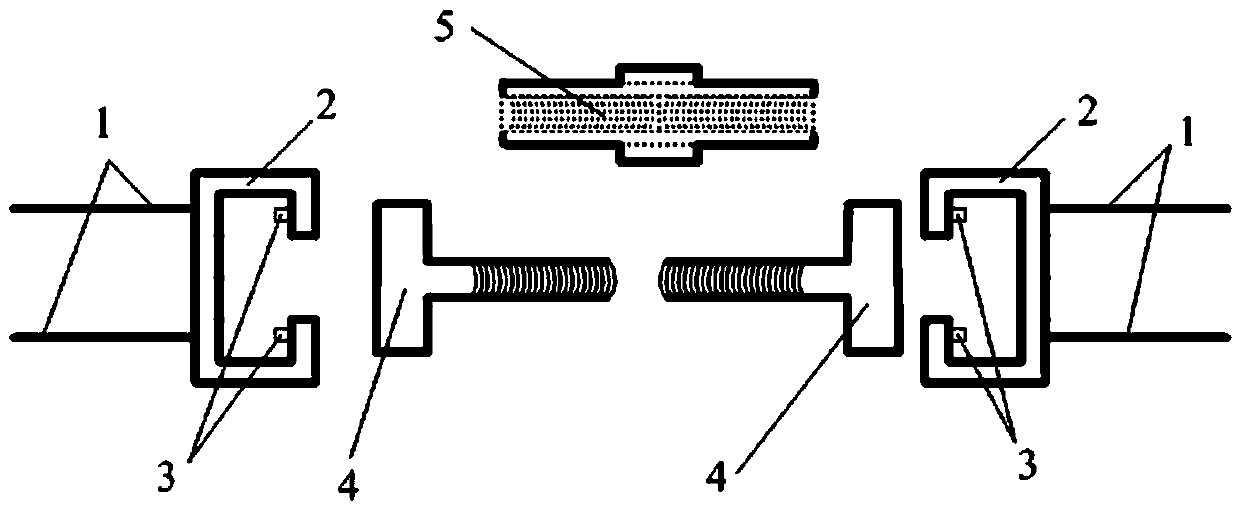

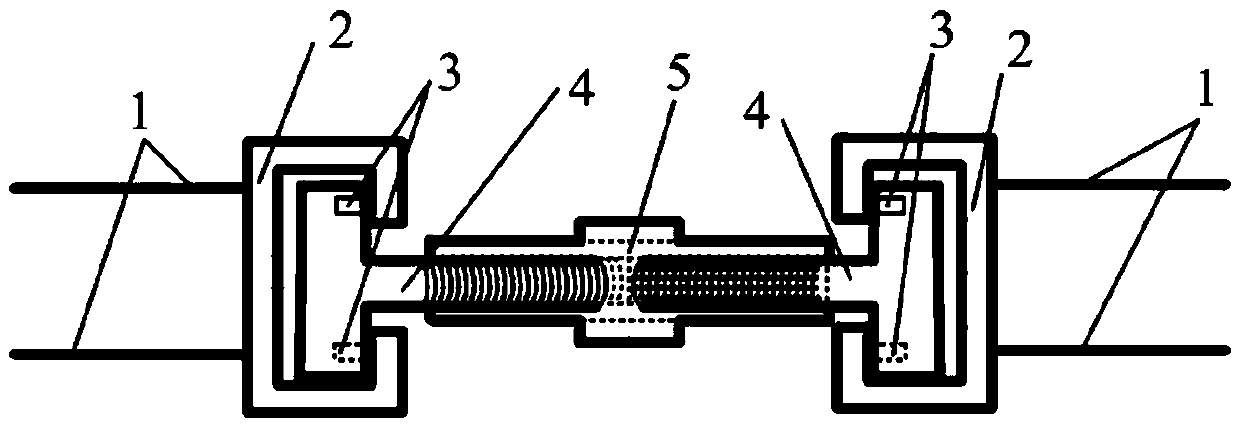

[0024] Such as figure 1 As shown, this embodiment provides an assembled partition wall connector, which is applied to an assembled partition wall, including an anchor sleeve 1, a connecting rod 4 and an adjusting sleeve 5, the anchor sleeve 1, the connecting rod 4, and the adjusting sleeve The centerlines of 5 are all on the same straight line.

[0025] Specifically, the anchor sleeve 1 is provided with a locking groove 2, and the locking groove 2 is provided with a limiting structure 3 for limiting the rotation of the connecting rod 4, and the limiting structure 3 in this embodiment stops the rotation of the needle.

[0026] In addition, the connecting rod 4 includes a terminal and a rod body, the terminal is in a rectangular structure and integrally formed with the rod body, the terminal is clamped with the locking groove 2 and locked with the anti-rotation pin. The rod body part is threadedly connected with the adjusting sleeve 5 .

[0027] The adjusting sleeve 5 is a pip...

Embodiment 2

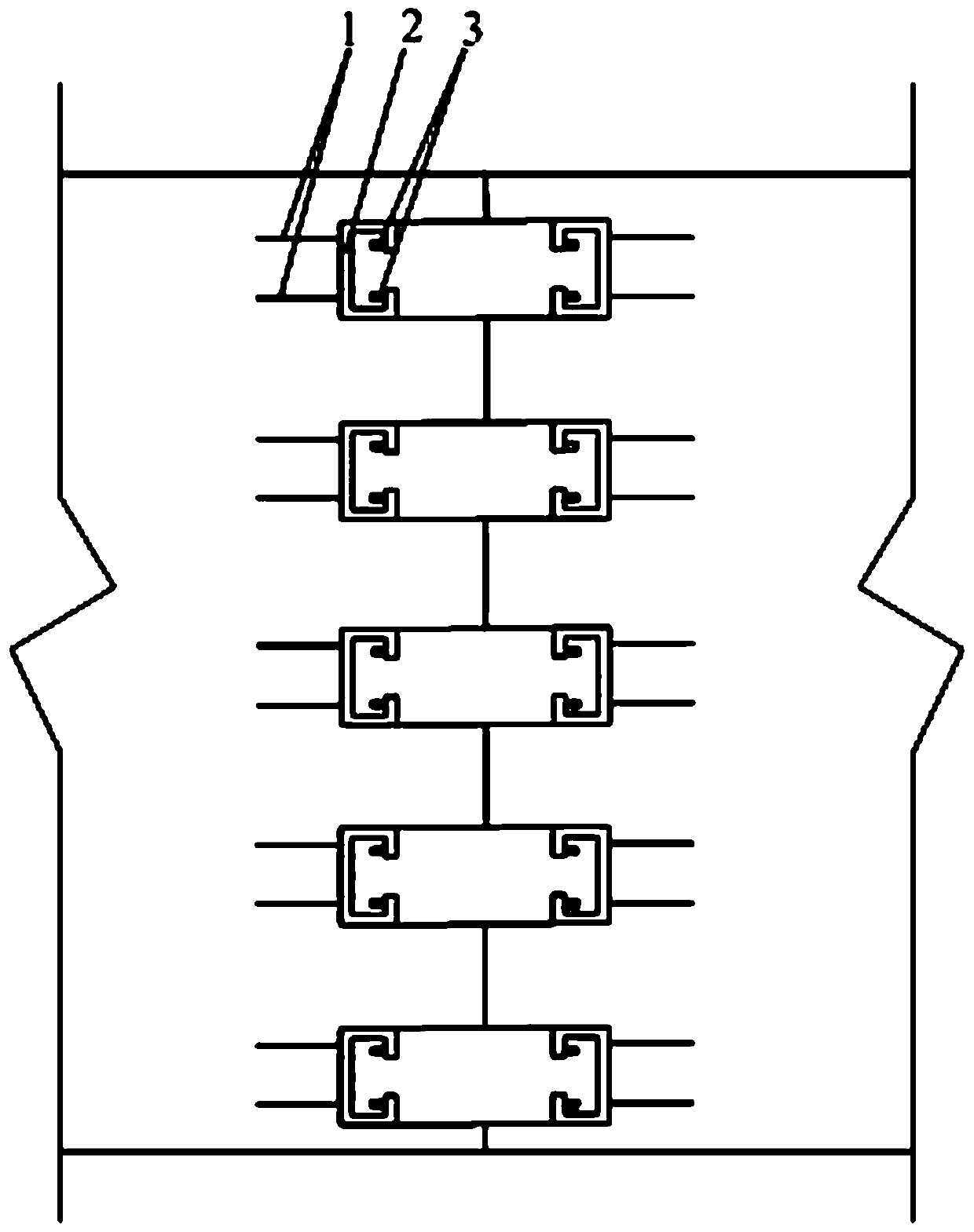

[0036] This implementation also provides a prefabricated partition wall connector. The structure and installation principle are the same as those in Embodiment 1. The difference is that this embodiment is used to connect a partition wall with a certain distance between the two sides, such as Figure 5 shown.

[0037] The method of use is as follows:

[0038] S1 cast the anchor sleeve 1 on the partition walls to be connected on both sides;

[0039] S2 uses the adjusting sleeve 5 to assemble the connecting rods 4 on both sides, and initially thread the connection;

[0040] S3 respectively clips the connecting rods 4 on both sides to the anchor sleeves 1 of the partition walls on both sides, and performs position limiting;

[0041] S4 uses a rotating tool to tighten the adjusting sleeve 5 and the connecting rods 4 on both sides, so as to realize the connection and fixation of the partition walls on both sides. The partition wall is connected by rotating the adjusting sleeve 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com