Squeeze and rub type double-height window reciprocal drum washing machine

A drum washing machine, drum technology, applied to other washing machines, washing machines with containers, washing machine control devices, etc., can solve the problems of cross-contamination of clothes, violent beating or vibration, and low washing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

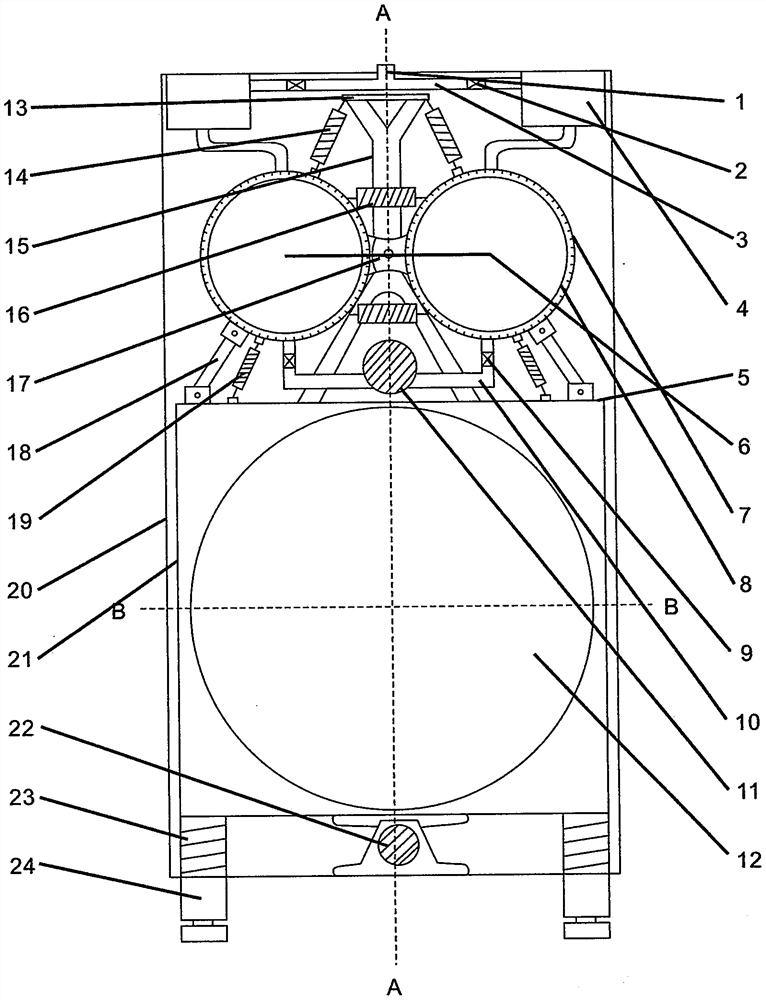

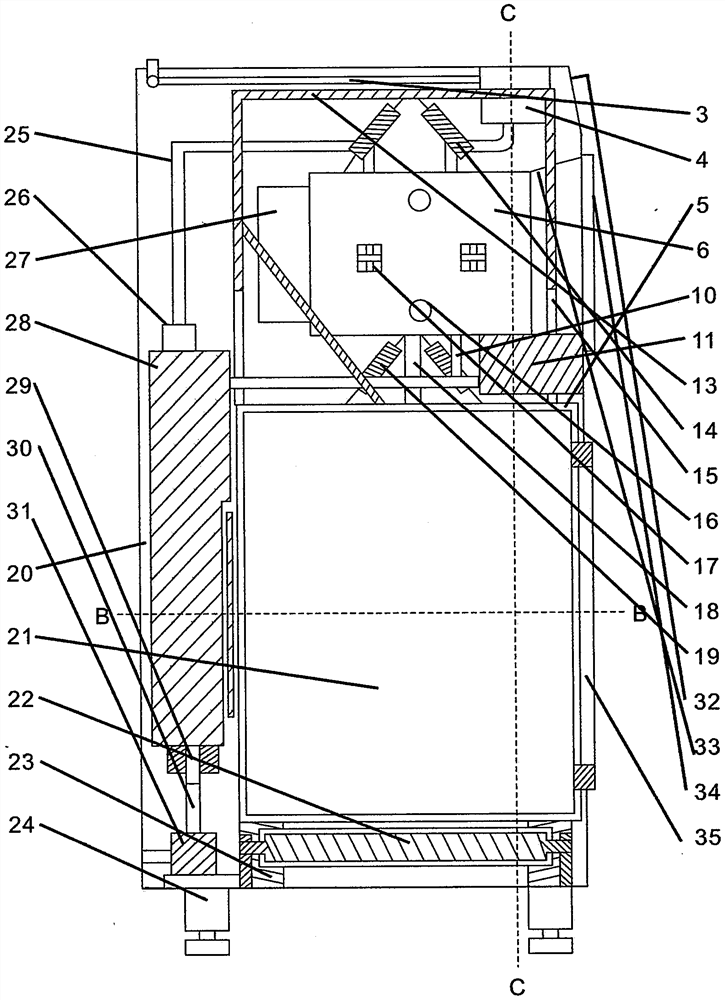

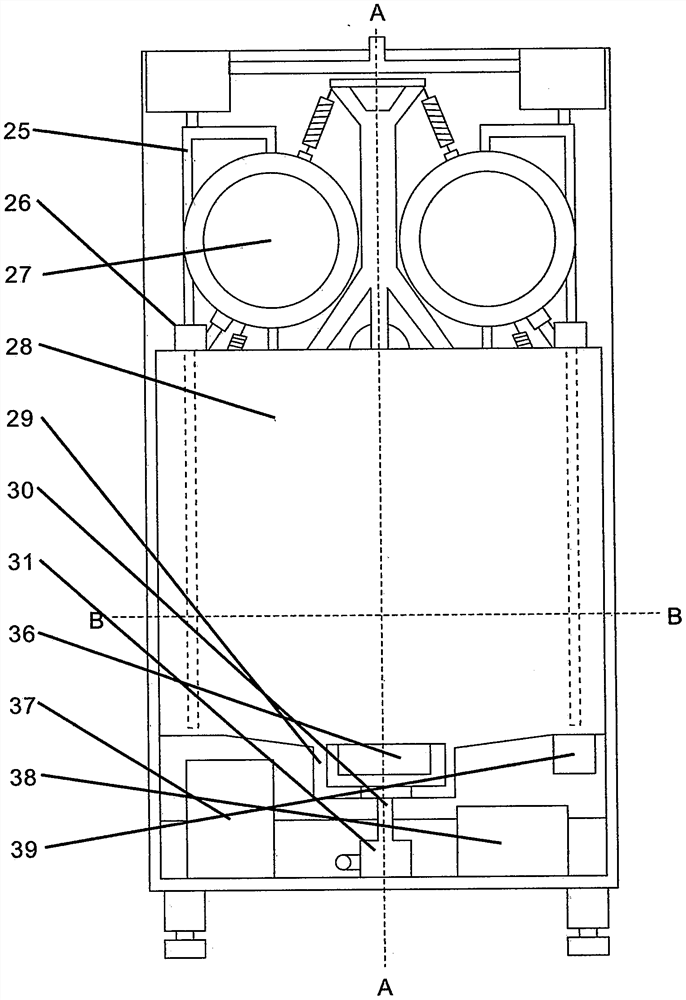

[0081] The technical solution of the present invention will be further described in detail in the following with reference to the accompanying drawings and in the form of specific embodiments.

[0082] This embodiment is the basic design (not limited to the product design) of the extruding and rubbing type double-height window reciprocal drum washing machine of the present invention. 8) The size is 300mm in diameter, 400mm in depth, 6 kg x 2 = 12 kg in washing capacity, the size of the dryer drum (12) is 680 mm in diameter, 550 mm in depth, 10 kg in dryer capacity, and the drum drive motor (27) rotates at a speed of The washing program is adjustable from 600 to 800 rpm, and the final dehydration program rotates at 1400 rpm.

[0083] like figure 1 , figure 2 , image 3 As shown, a top component mounting platform (5) is set at the middle and lower part of the body, and a box-shaped rocker type shock absorber (21) with a rotation damping balance mechanism is installed at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com