Preparation method for loosened porous cuprous oxide material and application of cuprous oxide in electrocatalytic reduction of carbon dioxide

A cuprous oxide, loose and porous technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of lack of research and achieve the effect of lowering the activation barrier, high carbon dioxide electrocatalytic reduction activity, and promoting reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

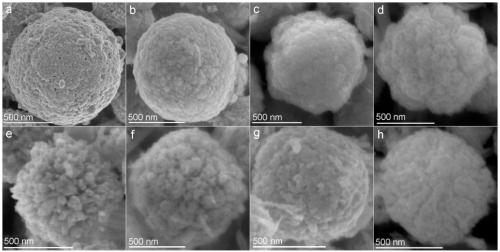

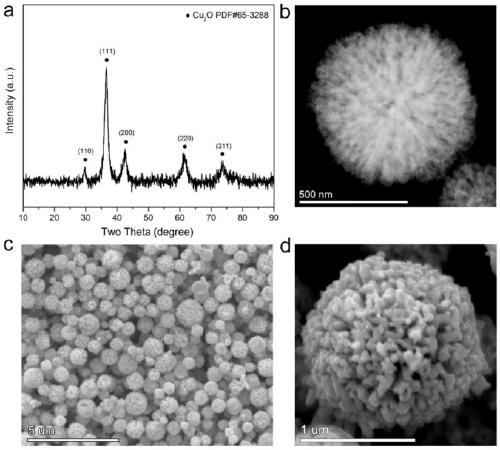

Image

Examples

Embodiment 1

[0033] (1) Wash the analytically pure cuprous iodide powder with 0.1mol / L HCl aqueous solution, remove the acid solution after oscillating and ultrasonically for 10 minutes, and then use N 2 The cuprous iodide powder was washed three times with ethanol after deoxygenation, and was washed with N 2 blow dry.

[0034] (2) Equip 15mL of 3M KI solution, add excess (>700mg) cuprous iodide powder obtained in step (1), place it in an oven at 60°C for 3 hours, and fully complex to obtain [CuI 2 ] - Complexing fluid.

[0035] (3) 2mL 2.5M NaOH solution is equipped in a 10mL beaker, and it is added to 10mL step (2) gained [CuI 2 ] - In the complexing solution, a large amount of orange-yellow precipitate was obtained.

[0036] (4) Divide the orange-yellow precipitate in the beaker into multiple large centrifuge tubes, centrifuge at 6000 rpm for 3 minutes, add ultrapure water to wash repeatedly, and centrifuge three times, then add acetone to wash and centrifuge twice , and then add ...

Embodiment 2

[0038] (1) Wash the analytically pure cuprous iodide powder with 0.1mol / L HCl aqueous solution, remove the acid solution after oscillating and ultrasonically for 10 minutes, and then use N 2 The cuprous iodide powder was washed three times with ethanol after deoxygenation, and was washed with N 2 blow dry.

[0039] (2) Equip 15mL of 5M KI solution, add excess (>1500mg) cuprous iodide powder obtained in step (1), put it in an oven at 60°C for 2 hours, and fully complex to obtain [CuI 2 ] - Complexing fluid.

[0040] (3) 3mL 3.0M NaOH solution is equipped in a 10mL beaker, and it is added to 10mL step (2) gained [CuI 2 ] - In the complexing solution, a large amount of orange-yellow precipitate was obtained.

[0041] (4) Divide the orange-yellow precipitate in the beaker into multiple large centrifuge tubes, centrifuge at 6000 rpm for 3 minutes, add ultrapure water to wash repeatedly, and centrifuge three times, then add acetone to wash and centrifuge twice , and then add a...

Embodiment 3

[0043] (1) Wash the analytically pure cuprous iodide powder with 0.1mol / L HCl aqueous solution, remove the acid solution after oscillating and ultrasonically for 10 minutes, and then use N 2 The cuprous iodide powder was washed three times with ethanol after deoxygenation, and was washed with N 2 blow dry.

[0044] (2) Equip 15mL of 8M KI solution, add excess (>2000mg) cuprous iodide powder obtained in step (1), place it in an oven at 60°C for 2 hours, and fully complex to obtain [CuI 2 ] - Complexing fluid.

[0045] (3) Equip 0.1M NaOH solution with a 500mL volumetric flask, and take out 250mL and place it in a 400mL beaker, then add 10mL of the obtained [CuI in step (2) 2 ] - complex solution, a large number of orange-yellow precipitates were obtained.

[0046] (4) Divide the orange-yellow precipitate in the beaker into multiple large centrifuge tubes, centrifuge at 6000 rpm for 3 minutes, add ultrapure water to wash repeatedly, and centrifuge three times, then add acet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com